Stainless Steel Pipe Weight Formula | Chart Metric | Square Pipe Weight Formula

Pipe Weight Formula In Kg | Plate Weight Formula Metric | Sheet Weight Formula | Tube Weight Formula | Aluminium Weight Formula Kg | Flat Bar Weight Calculator

Stainless Steel Sheet Weight Calculation Formula, Formula for Calculating SS Pipe Weight, Formula for Calculating SS Bar Weight, Formula for Calculating SS Square Bar Weight, Formula for Calculating SS Hexagonal Bar Weight, Formula for Calculating SS Flat Bar Weight, Formula for Calculating SS Sheet & Plates Weight

Formula for Calculating SS Circle Weight, Formula for Calculating Brass Pipe/ Copper Pipe Weight, Formula for Calculating Lead Pipe Weight, Formula for Calculating Aluminium Pipe Weight, Formula for Calculating Aluminium Sheet Weight, STEEL PIPE WEIGHT CALCULATOR, STAINLESS STEEL PIPE WEIGHT CALCULATOR

Stainless Steel Pipe Weight Formula | Chart Metric | Square Pipe Weight Formula

Stainless Steel Sheet Weight Calculation Formula

| 1. | Formula for Calculating S. S. Pipe Weight : |

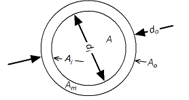

| 0.D. (mm) - W. Thick (mm) X W. Thick (mm) X 0.0248 = Wt. Per Mtr. Formula for calculating SS Pipe Weight

| |

| 2. | Formula for Calculating S. S. Bar Weight : |

| DIA (mm) X DIA (mm) X 0.00623 = Wt. Per Mtr. DIA (mm) X DIA (mm) X 0.0019 = Wt. Per Feet Formula for calculating SS Bar Weight | |

| 3. | Formula for Calculating S. S. Square Bar Weight : |

| DIA (mm) X DIA (mm) X 0.00788 = Wt. Per Mtr. DIA (mm) X DIA (mm) X 0.0024 = Wt. Per Feet Formula for calculating SS Square Weight | |

| 4. | Formula for Calculating S. S. Hexagonal Bar Weight: |

| DIA (mm) X DIA (mm) X 0.00680 = Wt. Per Mtr. DIA (mm) X DIA (mm) X 0.002072 = Wt. Per Feet Formula for calculating SS Hexagonal Weight | |

| 5. | Formula for Calculating S.S. Flat Bar Weight: |

| Width (mm) X Thick (mm) X 0.00798 = Wt. Per Mtr. Width (mm) X Thick (mm) X 0.00243 = Wt. Per Feet Formula for calculating SS Flat Bar Weight | |

| 6. | Formula for Calculating S.S. Sheet & Plates Weight: |

| Length (mtrs) X Width (mtrs) X Thick (mm) X 8.068 = Wt. Per PC. Length (feet) X Width (feet) X Thick (mm) X 3/4 = Wt. Per PC Formula for calculating SS Sheet & Plates Weight | |

| 7. | Formula for Calculating S.S. Circle Weight: |

| Dia (mm) X Dia (mm) X Thick (mm) ÷ 160 = Gms. Per PC Dia (mm) X Dia (mm) X Thick (mm) X 0.0000063 = Wt. Per PC Formula for calculating SS Pipe Weight | |

| 8. | Formula for Calculating Brass Pipe/ Copper Pipe Weight: |

O. D. (mm) - Thick (mm) X Thick (mm) X 0.0260 = Wt. Per Mtr. Formula for calculating SS Pipe Weight | |

| 9. | Formula for Calculating Lead Pipe Weight: |

O. D. (mm) - Thick (mm) X Thick (mm) X 0.0345 = Wt. Per Mtr. Formula for calculating Lead Pipe Weight | |

| 10. | Formula for Calculating Aluminium Pipe Weight: |

O. D. (mm) - Thick (mm) X Thick (mm) X 0.008 = Wt. Per Mtr. Formula for calculating Aluminium Pipe Weight | |

| 11. | Formula for Calculating Aluminium Sheet Weight: |

Length (Mtr.) X Width (Mtr.) X Thick (mm) 2.69 = Wt. Per PC Formula for calculating SS Pipe Weight | |

| 12. | Conversion of Mtrs to Feet: |

| Weight of 1 Mtrs ÷ 3.2808 = Weight Per Feet | |

| 13. | Bar Low's Formula for Calculating Bursting Pressure: |

| P = 2ST/D or t-DP/25S or S-DP/2t or D = 2st /P P = Bursting Pressure Psi. S = Tensile Strength of Tube T = Wall Thickness (in inches) D = Outside Diameter (in inches) |

Stainless Steel Pipe Material | Stainless Steel Pipe Material Grade | Stainless Steel Pipe Material Specification

316 / 316L STAINLESS STEEL PIPE GRADES

These grades of austenitic stainless steels are similar to 304 and 304L, but with the addition of molybdenum. The addition of molybdenum improves the alloys corrosion resistance, particularly with higher resistance to pitting and crevice corrosion in chloride environments. The austenitic structure allows excellent toughness, even down to cryogenic temperatures. These grades have excellent weld-ability, with or without the addition of filler metal.

Stock Size Range and Specifications:

Seamless product

NPS:1/8” through 24”

Schedules: 5, 10S, 10, 30, 40S, 40, 80, 80S

Specifications: ASTM A312, ASME SA312

Welded product

NPS:1/8” through 8”

Schedules:10, 40, 80, 160, XXH

Specifications: ASTM A312,ASME SA312

Corrosion tested to MIL-P-24691/3 or A262 Practice E

| Weight % | C | Mn | P | S | Si | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|

| 316 | .08 | 2.00 | .045 | .030 | 1.00 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

| 316L | .035 | 2.00 | .045 | .030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| Grade | Tensile | ||||

|---|---|---|---|---|---|

| Ultimate/Min | Yield/Min | Elongation/Min | |||

| KSI | MPA | KSI | MPA | % | |

| 316 | 75 | 515 | 30 | 205 | 35 |

| 316L | 70 | 485 | 25 | 170 | 35 |

304 / 304L STAINLESS STEEL PIPE GRADES

These grades of austenitic stainless steels are the most versatile and widely used stainless steels. They exhibit excellent corrosion resistance to a wide range of corrosive environments. Type 304 and 304L grades of stainless steel pipe exhibit good machinability and have excellent weld-ability characteristics with or without the addition of filler metals.

Stock Size Range and Specifications:

Seamless product

MPS:1/8" through 24"

Schedules:5, 10, 10S, 20, 30, 40, 40S, 80, 80S

Specifications: ASTM A312, ASME SA312

Welded product

NPS:1/8" through 12"

Schedules:5, 10, 40, 80, 160, XXH

Specifications: ASTM A312,ASME SA312

Corrosion tested to MIL-P-24691/3 or A262 Practice E

| Weight % | C | Mn | P | S | Si | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 304 | .08 | 2.00 | .045 | .030 | 1.00 | 18.0-20.0 | 8.0-11.0 |

| 304L | .035 | 2.00 | .045 | .030 | 1.00 | 18.0-20.0 | 8.0-13.0 |

| Grade | Tensile | ||||

|---|---|---|---|---|---|

| Ultimate/Min | Yield/Min | Elongation/Min | |||

| KSI | MPA | KSI | MPA | % | |

| 304 | 75 | 515 | 30 | 205 | 35 |

| 304L | 70 | 485 | 25 | 170 | 35 |

Stainless Steel Tube, Pipe and Fittings Product Specifications

Stainless Steel Tube and Fittings

| Standard | Description |

| ASTM A213/A213M | Seamless ferritic and austenitic alloy steel boiler, superheater and heat exchanger tubes. |

| ASTM A249/A249M | Welded austenitic steel boiler, superheater, heat exchanger and condenser tubes. |

| ASTM A269 | Seamless and welded austenitic stainless steel tubing for general purposes. |

| ASTM A270 | Seamless and welded austenitic stainless steel sanitary tubing. |

| ASTM A450/A450M | General requirements for carbon, ferritic alloy and austenitic alloy steel tubes. |

| ASTM A554 | Welded stainless steel mechanical tubing. |

| ASTM A791/A791M | Welded unannealed ferritic stainless steel tubing. |

| ASTM A789/A789M | Seamless and welded ferritic/austenitic stainless steel tubing for general service. |

| AS1163 | Structural steel hollow sections (dimensional tolerances). |

| AS1528, Parts 1 to 4 | Tubes (stainless steel) and tube fittings for the food industry. |

| Higher austenitic | |

| ASTM B674 | UNS N08904 welded tube. |

| ASTM B677 | UNS N08904 seamless pipe and tube. |

Stainless Steel Pipe

| Standard | Description |

| ASTM A312/A312M | Seamless and welded austenitic stainless steel pipe. |

| ASTM A358/A358M | Electric-Fusion-Welded (EFW) austenitic chromium-nickel alloy steel pipe for high temperature service. |

| ASTM A409/A409M | Welded large diameter austenitic steel pipe for corrosive or high temperature service. |

| ASTM A731/A731M | Seamless and welded ferritic and martensitic stainless steel pipe. |

| ASTM A790/A790M | Seamless and welded ferritic/austenitic stainless steel pipe. |

| ASTM A450/A450M | General requirements for carbon, ferritic alloy and austenitic alloy steel tubes. |

| ASTM A530/A530M | General requirements for specialised carbon and alloy steel pipe. |

| JIS G3459 | Stainless steel pipes. |

| ANSI/ASME B36.10M | Welded and seamless wrought steel pipe. |

| ANSI/ASME B36.19M | Stainless steel pipe. |

| Higher austenitic | |

| ASTM A673 | UNS N08904 welded pipe. |

| ASTM A677 | UNS N08904 seamless pipe and tube. |

Stainless Steel Pipe Fittings and Flanges

| Standard | Description |

| ASTM A182/A182M | Forged or rolled alloy steel pipe flanges, forged fittings and valves and parts for high temperature service. |

| ASTM A403/A403M | Wrought austenitic stainless steel piping fittings. |

| ASTM A815/A815M | Wrought ferritic, ferritic/austenitic and martensitic stainless steel piping fittings. |

| AS 2129 | Flanges for pipes, valves and fittings |

| ANSI/ASME B1.20.1 | Pipe threads, general purpose (inch). |

| ANSI B16.5 | Steel pipe flanges and flanged fittings. |

| ANSI B16.9 | Factory-made wrought steel butt-welding fittings. |

| ANSI B16.11 | Forged steel fittings socket-welding and threaded. |

| ANSI B16.25 | Butt-welding ends. |

| MSS SP43 | Wrought stainless steel butt-welding fittings. |

| BS21 | Threading. |

| ISO 4144 | Stainless steel fittings threaded to ISO 7-1. |

austenitic steel tubing, austenitic stainless steel tubes, austenitic stainless steel pipe, seamless austenitic stainless steel tube

Austenitic stainless steel tubes

Formable tubes for versatile use

Austenitic stainless steel is the most used stainless material in the world. The standard grades for everyday business are covered mainly by 304 and 316L/316Ti types of austenitics.

Austenitic stainless steel sustains its mechanical values, even at higher temperatures. This sustainability of mechanical values makes it possible to obtain 30-minute fire resistance in stainless steel structures, without any additional fire protection.

Advantages of austenitic stainless steel:

• Excellent formability

• Excellent corrosion resistance

• Toughness at low temperatures

• Good weldability

• Fire resistance

• Austenitic metric (1.4301, 1.4307, 1.4404, 1.4571)

• Austenitic imperial (304, 304L, 316L, 316 Ti)

• Also special project materials by request

316 / 316L STAINLESS STEEL PIPE

These grades of austenitic stainless steels are similar to 304 and 304L, but with the addition of molybdenum. The addition of molybdenum improves the alloys corrosion resistance, particularly with higher resistance to pitting and crevice corrosion in chloride environments. The austenitic structure allows excellent toughness, even down to cryogenic temperatures. These grades have excellent weld-ability, with or without the addition of filler metal.

SHOP 316 / 316L STAINLESS STEEL PIPE

Stock Size Range and Specifications:

Seamless product

NPS:1/8” through 24” Schedules: 5, 10S, 10, 30, 40S, 40, 80, 80SSpecifications: ASTM A312, ASME SA312

Welded product

NPS:1/8” through 8” Schedules: 10, 40, 80, 160, XXHSpecifications: ASTM A312,ASME SA312

Corrosion tested to MIL-P-24691/3 or A262 Practice E

| Weight % | C | Mn | P | S | Si | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|

| 316 | .08 | 2.00 | .045 | .030 | 1.00 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

| 316L | .035 | 2.00 | .045 | .030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| Grade | Tensile | ||||

|---|---|---|---|---|---|

| Ultimate/Min | Yield/Min | Elongation/Min | |||

| KSI | MPA | KSI | MPA | % | |

| 316 | 75 | 515 | 30 | 205 | 35 |

| 316L | 70 | 485 | 25 | 170 | 35 |

Stainless Steel Tube Specefication

| Spec. No. | Title | Scope |

| ASTM A 213 ASME SA 213 | Seamless Ferritic Stainless Steel and Austenitic Stainless Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes. | Pressure tubes, made from 16 grades of austenitic stainless steel and from 12 grades of ferritic Cr-Mo Alloy Steel. |

| ASTM A 249 ASME SA 249 | Welded Austenitic Stainless Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes. | Pressure tubes, made from austenitic stainless steels, (Types 304, 304H, 304L, 305, 309, 310, 316, 316H, 316L, 317, 321, 321H, 347, 347H, 348, 348H, and XM grades.) |

| ASTM A 268 ASME SA 268 | Seamless and Welded Ferritic Stainless Steel Tubing for General Service. | 15 grades of ferritic stainless steel tubing for general corrosion resistance and high temperature service. (Types 329, 405, 409, 410, 429, 430, 430Ti, 443, 446, XMs & others). |

| ASTM A 269 | Seamless and Welded Austenitic Stainless Steel Tubing for General Service. | 13 grades of austenitic stainless steel tubing for general corrosion-resisting and high-temperature service. (Types 304, 304L, 316, 316L, 317, 321, 347, 348 and XM grades). |

| ASTM A 270 | Seamless and Welded Austenitic Stainless Steel Sanitary Tubing. | Austenitic stainless steel tubing intended for use in the diary and food industry in sizes up to and including 4 in. in outside diameter. |

| ASTM A 312 ASME SA 312 | Seamless and Welded Austenitic Stainless Steel Pipe. | Austenitic stainless steel pipe intended for high temperature and general corrosive service. 22 grades are covered. |

| ASTM A 358 ASME SA 358 | Electric-Fusion-Welded Austenitic Chromium-Nickel Alloy Steel Pipe for High-Temperature Service. | For corrosion and high temperature service, normally not less than 8 in. nominal diameter. Types 304, 316, 309, 310, 321, 347, 304L, 316L, 304H, 316H. |

| ASTM A 376 ASME SA 376 | Seamless Austenitic Stainless Steel Pipe for High-Temp Central-Station Service. | Austenitic stainless steel pipe intended for high temperature and general corrosive service. Better surface than A312 pipe. |

| ASTM A 409 ASME SA 409 | Welded Large Outside Diameter Light Wall Austenitic Chromium-Nickel Alloy Steel Pipe for Corrosive or High Temperature Service. | Nominal diameter 14-30 in. in Schedules 5S and l0S. Types 304, 309, 310, 316, 317, 321, 347, 348, 304L, 316L. |

| ASTM A 450 ASME SA 450 | General requirements for Alloy Steel Tubes. | Common requirements for ASTM tubular specifications. |

| ASTM A 511 | Seamless Stainless Steel Mechanical Tubing. | 27 grades are covered for mechanical applications. Primarily round tubing. |

| ASTM A 530 ASME SA 530 | General Requirements for Carbon, Ferritic Alloy, and Austenitic Alloy Steel Pipe. | Common requirements for ASTM pipe specifications as listed. |

| ASTM A 554 | Welded Stainless Steel Mechanical Tubing. | Nineteen grades are covered for mechanical applications. Rounds, squares, rectangles, and special shapes are included. |

| ASTM A 632 | Seamless and Welded Austenitic Stainless Steel Tubing for General Service. Small Diameter. | 9 grades of austenitic stainless steel tubing for general corrosion-resisting and high-temperature service. |

| AMS 556 | Steel Tubing, Corrosion and Heat Resistant 18 Cr; 11 Ni; (Cb + Ta) (SAE 30347) Hydraulic. | Annealed type 321 hydraulic line tubing. Type 1-Seamless Type 2-Welded & Drawn |

| AMS 5557 | Steel Tubing, Corrosion and Heat Resistant 18 Cr; 11 Ni; Ti (SAE 30321)Hydraulic | Annealed type 347 hydraulic line tubing. Type 1-Seamless Type 2-Welded & Drawn |

| AMS 5558 | Steel Tubing, Welded, Corrosion and Heat Resistant 18 Cr; 11 Ni, (Cb + Ta)(SAE 30348) Thin Wall. | High pressure ducting, wall thickness 2% of O.D. or less. Weld bead controlled, X-ray. |

| AMS 5559 | Steel Tubing, Welded, Corrosion and Heat Resistant 18 Cr, 10 Ni, Ti, (SAE 30321) Thin Wall. | High pressure ducting, wall thickness 2% of O.D. or less. Weld bead controlled, X-ray. |

| AMS 5560 | Steel Tubing, Seamless Corrosion Resistant 19 Cr; 9 Ni (SAE 30304). | Annealed type 304 aircraft hydraulic fine tubing. (Not subject to high pressure). Structural. |

| AMS 5561 | Steel Tubing, Welded and Drawn Corrosion Resistant 21 Cr; 6 Ni; 9 Mn High Pressure Hydraulic. | For parts and assemblies such as fluid lines subject to high pressure and requiring corrosion resistance. 1/8 - 1/4 Hard. |

| AMS 5562 | Steel Tubing, Seamless Corrosion Resistant 21 Cr; 6 Ni; 9 Mn Annealed. | Parts and assemblies requiring both corrosion and heat resistance, and having higher strength than 18-8 types. |

| AMS 5565 | Steel Tubing, Welded, Corrosion Resistant 19 Cr; 6 Ni (SAE 30304). | Annealed type 304 aircraft hydraulic line tubing. (Not subject to high pressure), Structural. |

| AMS 5566 | Steel Tubing, Seamless or Welded Corrosion Resistant 19 Cr; 10 N (SAE 30304) High Pressure Hydraulic | Cold drawn type 304, high pressure, aircraft hydraulic line tubing. 1/8 hard. Type 1óSeamless Type 2óWelded & Drawn |

| AMS 5567 | Steel Tubing, Seamless or Welded Corrosion Resistant 19Cr; 10 Ni (SAE 30304) Hydraulic, Solution Treated. | Fluid lines subject to medium high pressures requiring corrosion resistance. Annealed.(1) Seamless (2) Welded & Drawn |

| AMS 5570 | Steel Tubing, Seamless Corrosion and Heat Resistant 18 Cr; 10 Ni; Ti (SAE 30321). Annealed Structural. | Parts and assemblies requiring both corrosion and heat resistance especially when such parts are welded during fabrication. Requiring oxidation resistance up to approximately 1500?F, but useful at that temperature only when stresses are low. |

| AMS 5571 | Steel Tubing, Seamless Corrosion and Heat Resistant 18 Cr; 11 Ni; (Cb + Ta) (SAE 30347). Annealed Structural. | Parts and assemblies requiring both corrosion and heat resistance especially when such parts are welded during fabrication. Requiring oxidation resistance up to approximately 1500?F, but useful at that temperature only when stresses are low. |

| AMS 5572 | Steel Tubing, Seamless Corrosion and Heat Resistant 25 Cr; 20 Ni (SAE 30310). Annealed Structural. | Parts and assemblies requiring both corrosion and heat resistance especially when welded during fabrication, Requiring oxidation resistance up to approximately 2000?F, but useful at that temperature only when stresses are low. |

| AMS 5573 | Seamless Type 316 Annealed Structural | Parts & assemblies requirinq,,both corrosion and heat resistance up to 1600?F. |

| AMS 5574 | Seamless Type 309S Annealed Structural | Parts & assemblies requiring both corrosion and heat resistance up to 2000?F, especially welded assemblies. |

| AMS 5575 | Steel Tubing, Seamless Corrosion and Heat Resistant 18 Cr; 11 Ni; (Gb + Ta) (SAE 30347). Annealed Structural. | Parts and assemblies requiring both corrosion and heat resistance especially when such parts are welded during fabrication. Requiring oxidation resistance up to approximately 1500?F, but useful at that temperature only when stresses are low. |

| AMS 5576 | Steel Tubing. Welded, Corrosion and Heat Resistant 18 Cr; 10 Ni; Ti (SAE 30321). Annealed Structural. | Parts and assemblies requiring both corrosion and heat resistance especially when such parts are welded during fabrication. Requiring oxidation resistance up to approximately 1500?F, but useful at that temperature only when stresses are low. |

| AMS 5577 | Steel Tubing, Welded, Corrosion and Heat Resistant 25 Cr; 20 Ni; (SAE 30310). Annealed Structural. | Parts and assemblies requiring both corrosion and heat resistance especially when welded during fabrication. Requiring oxidation resistance up to approximately 2000?F, but useful at that temperature only when stresses are low. |

| AMS 5639 | Seamless Type 304 | Cold Finished Mechanical Tube Rockwell 90B max Hardness Corrosion Embrittlement Capability |

| AMS 5645 | Seamless Type 321 | Cold Finished Mechanical Tube Rockwell 90B max Hardness Corrosion Embrittlement Capability |

| AMS 5546 | Seamless Type 347 | Cold Finished Mechanical Tube Rockwell 90B max Hardness Corrosion Embrittlement Capability |

| AMS 5647 | Seamless Type 304L | Cold Finished Mechanical Tube Rockwell 90B max Hardness Corrosion Embrittlement Capability |

| AMS 5648 | Seamless Type 316 | Cold Finished Mechanical Tube Rockwell 90B max Hardness |

| MIL-T-5695 | Tubing, Steel, Corrosion Resistant, (304) Cold Drawn (1/2 or 1/4 Hard) Smls or W&D. | Intended for use in the fabrication of aircraft structural parts requiring a high degree of resistance to corrosion. |

| MIL-T-6737 (T 321) | Tubing, Steel, Corrosion and Heat Resistant (18-8 Stabilized), Welded.Annealed. | Type 321 and 347 tubing intended for use in the manufactured exhaust-stacks, manifolds, blast tubes, ring collectors and similar applications where a weldable corrosion and heat resisting steel is required or for use at 8000 - 1500?F. |

| MIL-T-6845 (T304) | Tubing, Steel, Corrosion Resistant (304) Aerospace Vehicle Hydraulic System. 1/8 Hard, Seamless, Welded & Drawn. | Intended for use in high pressure hydraulic and pneumatic systems in which corrosion resistant materials are required. The tubing is not suitable for use in applications assembled by welding or brazing or exposed to temperatures higher than 800?F, because of impaired resistance to corrosion, where subsequent anneal not possible. |

| MIL-T-8504 (T 304) | Tubing, Steel, Corrosion Resistant (18-8) Annealed, Aircraft Hydraulic System. Seamless, Welded. | Intended for use in high pressure hydraulic and pneumatic systems in which corrosion resistant materials are required. This tubing is of lower strength and higher ductility than tubing to Specification MIL-T-6845. May be used to replace MIL-T-6845 tubing but heavier wall thicknesses must be used:Same qualifications regarding welding, brazing & temperature. |

| MIL-T-8506 (T 304) | Tubing, Steel, Corrosion Resistant, (304) Annealed, Seamless, Welded. | Intended for use in the fabrication of aircraft parts requiring a high degree of resistance to corrosion. Not to be used in high pressure hydraulic control systems. |

| MILT 8606 (T 304L) (T 321) (T 347) | Tubing, Steal, Corrosion Resistant (18-8 Stabilized). Annealed. Seamless, Welded & Drawn. | Intended for use in applications which require a high degree of resistance to corrosion or to temperatures in the range of 800?F-1500?F. or in applications which involve welding. Suitble for use in tank-automotive equipment for hydraulic and mechanical applications. |

| MlL-T-8808 (T 321) (T 347) | Tubing, Steel, Corrosion Resistant (l8-8 Stabilized), Aircraft Hydraulic Quality. Annealed, Seamless, Welded & Drawn. | Intended for use in high pressure hydraulic and pneumatic systems where corrosion and heat resistance are required and in which welding or brazing may be involved during fabrication. Resists oxidation at temperatures to 1200?F, but is useful at that temperature only when stresses are low. |

| MIL-T4973 (T 304L) (T 316L) (T 321) (T 347) | Tubing, Steel, Corrosion Resistant, Aerospace Vehicle Hydraulic System. 1/8Hard. Seamless, Welded & Drawn. | Intended for use in high pressure hydraulic and pneumatic systems where corrosion and heat resistance are required and in which welding or brazing may be involved during fabrication. Suitable for use in temperatures to 1200?F, when stresses are low. |

| MIL-P-1144 (T 304) (T 304L) (T 316) (T 316L) (T 321) (T 347) | Pipe, Stainless Steel, (Corrosion Resisting). Seamless or Welded. Annealed. | Pipe is intended for high-temperature and hydraulic br other pressure service under general corrosive conditions. |

Stainless Steel Pipe Weights and Dimensions

Black - Indicates wall thickness in inches.

Red - Indicates weight per foot in pounds.

| PIPE SIZE | O.D. | 5s | True 5 | 10s | True 10 | 20 | 30 | True 40 | STD. | 60 | True 80 | XH | 100 | 120 | 140 | True 160 | XXH |

| 1/8 | 0.405 | .035 .1383 | .049 .1863 | .049 .1863 | .068 .2447 | .0668 .2447 | .095 .3145 | .095 .3145 | |||||||||

| 1/4 | 0.540 | .049 .2570 | .065 . 3297 | .065 .3297 | .088 .4248 | .088 .4248 | .119 .5351 | .119 .5351 | |||||||||

| 3/8 | 0.675 | .049 .3276 | .065 .4235 | .065 .4235 | .091 .5676 | .091 .5676 | .126 .7388 | .126 .7388 | |||||||||

| 1/2 | 0.840 | .065 .5383 | .065 .5380 | .083 .6710 | .083 .6710 | .109 .8510 | .109 .8510 | .147 1.088 | .147 1.088 | .187 1.304 | .294 1.714 | ||||||

| 3/4 | 1.050 | .065 .6838 | .065 .6838 | .083 .8572 | .083 .8572 | .113 1.131 | .113 1.131 | .154 1.474 | .154 1.474 | .218 1.937 | .308 2.441 | ||||||

| 1 | 1.315 | .065 .8678 | .065 .8678 | .109 1.404 | .109 1.404 | .133 1.679 | .133 1.679 | .179 2.172 | .179 2.172 | .250 3.765 | .382 5.214 | ||||||

| 1 1/4 | 1.660 | .065 1.107 | .065 1.107 | .109 1.806 | .109 1.806 | .140 2.273 | .140 2.273 | .191 2.997 | .191 2.997 | .250 3.765 | .382 5.214 | ||||||

| 1 1/2 | 1.900 | .065 1.274 | .065 1.274 | .109 2.085 | .109 2.085 | .145 2.718 | .145 2.718 | .200 3.631 | .200 3.631 | .281 4.859 | .400 6.408 | ||||||

| 2 | 2.375 | .065 1.604 | .065 1.604 | .109 2.638 | .109 2.638 | .154 3.653 | .154 3.653 | .218 5.022 | .218 5.022 | .343 7.444 | .436 9.029 | ||||||

| 2 1/2 | 2.875 | .083 2.475 | .083 2.475 | .120 3.531 | .120 3.531 | .203 5.793 | .203 5.793 | .276 7.661 | .276 7.661 | .375 10.01 | .552 13.70 | ||||||

| 3 | 3.5 | .083 3.029 | .083 3.029 | .120 4.332 | .120 4.332 | .216 7.576 | .216 7.576 | .300 10.25 | .300 10.25 | .438 14.32 | .600 18.58 | ||||||

| 3 1/2 | 4.0 | .083 3.472 | .083 3.472 | .120 4.973 | .120 4.973 | .226 9.109 | .226 9.109 | .318 12.51 | .318 12.51 | .636 22.85 | |||||||

| 4 | 4.5 | .083 3.915 | .083 3.915 | .120 5.613 | .120 5.613 | .237 10.79 | .237 10.79 | .281 12.66 | .337 14.98 | .337 14.98 | .438 19.00 | .531 22.51 | .674 27.54 | ||||

| 4 1/2 | 5.0 | .247 12.53 | .355 17.61 | .710 32.53 | |||||||||||||

| 5 | 5.563 | .109 6.349 | .109 6.349 | .134 7.770 | .134 7.770 | .258 14.62 | .258 14.62 | .375 20.78 | .375 20.78 | .500 27.04 | .625 32.96 | .750 38.55 | |||||

| 6 | 6.625 | .109 7.585 | .109 7.585 | .134 9.290 | .134 9.289 | .280 18.97 | .280 18.97 | .432 28.57 | .432 28.57 | .562 36.39 | .719 45.30 | .864 53.16 | |||||

| 7 | 7.625 | .301 23.57 | .500 38.05 | .875 63.08 | |||||||||||||

| 8 | 8.625 | .109 9.914 | .109 9.914 | .148 13.40 | .148 13.40 | .250 22.36 | .277 24.70 | .322 28.55 | .322 28.55 | .406 35.64 | .500 43.39 | .500 43.39 | .594 50.87 | .719 60.63 | .812 67.76 | .906 74.69 | .875 72.42 |

| 9 | 9.625 | .342 33.90 | .500 48.72 | ||||||||||||||

| 10 | 10.75 | .134 15.19 | .134 15.19 | .165 18.65 | .165 18.70 | .250 28.04 | .307 34.24 | .365 40.48 | .365 40.48 | .500 54.74 | .594 64.33 | .500 54.74 | .719 76.93 | .844 89.20 | 1.000 104.1 | 1.125 115.6 | |

| 11 | 11.75 | .375 45.55 | .500 60.07 | ||||||||||||||

| 12 | 12.75 | .156 21.07 | .165 22.18 | .180 24.16 | .180 24.20 | .250 33.38 | .330 43.77 | .406 53.53 | .375 49.56 | .562 73.16 | .688 88.51 | .500 65.42 | .844 107.2 | 1.000 125.5 | 1.125 139.7 | 1.312 160.3 | |

| 14 | 14.0 | .156 23.07 | .188 27.73 | .250 36.71 | .312 45.68 | .375 54.57 | .437 63.37 | .375 54.57 | .594 84.91 | .750 106.1 | .500 72.09 | .938 130.7 | 1.094 150.7 | 1.250 170.2 | 1.406 189.1 | ||

| 16 | 16.0 | .165 27.90 | .188 31.75 | .250 42.05 | .312 52.36 | .375 62.58 | .500 82.77 | .375 62.58 | .656 107.5 | .844 136.5 | .500 82.77 | 1.031 164.8 | 1.219 192.3 | 1.438 223.5 | 1.593 245.1 | ||

| 18 | 18.0 | .165 31.43 | .188 35.76 | .250 47.39 | .312 59.03 | .437 82.06 | .562 104.8 | .375 70.59 | .750 138.2 | .938 170.8 | .500 93.45 | 1.156 208.0 | 1.375 244.1 | 1.562 274.2 | 1.781 308.5 | ||

| 20 | 20.0 | .188 39.78 | .218 46.05 | .250 52.73 | .375 78.60 | .500 104.1 | .594 122.9 | .375 78.60 | .812 166.4 | 1.031 208.9 | .500 104.1 | 1.281 256.1 | 1.500 296.4 | 1.750 341.1 | 1.968 379.0 | ||

| 22 | 22.0 | .250 58.07 | .375 86.61 | .500 114.81 | .375 86.61 | .875 197.42 | 1.125 250.82 | .500 114.81 | 1.357 302.88 | 1.625 353.61 | 1.875 403.01 | 2.125 451.07 | |||||

| 24 | 24.0 | .218 55.37 | .250 63.41 | .250 63.41 | .375 94.62 | .562 140.8 | .687 171.2 | .375 94.62 | .969 238.1 | 1.219 296.4 | .500 125.5 | 1.531 367.4 | 1.812 429.4 | 2.062 483.1 | 2.343 541.9 | ||

| 26 | 26.0 | .312 85.73 | .375 102.63 | .500 136.17 | |||||||||||||

| 30 | 30.0 | .250 79.43 | .312 98.93 | .312 99.08 | .625 196.08 | .375 118.65 | .500 157.53 | ||||||||||

| 34 | 34.0 | .312 112.43 | .625 222.78 | .688 244.60 | .375 134.67 | .500 178.89 | |||||||||||

| 36 | 36.0 | .312 119.11 | .625 236.13 | .688 282.36 | .375 142.68 | .500 189.57 | |||||||||||

| 42 | 42.0 | .625 276.17 | .688 330.41 | .375 166.71 | .500 221.61 | ||||||||||||

| PIPE SIZE | O.D. | 5s | True 5 | 10s | True 10 | 20 | 30 | True 40 | STD. | 60 | True 80 | XH | 100 | 120 | 140 | True 160 | XXH |

Stainless Steel Pipe 316L

Rs 260/ Kilogram

ASTM A 312 TP 316L Seamless Pipe

Rs 150/ Meter

Price SS Stainless Steel Welded Pipes & Tubes ( 304)

Stainless Steel Welded Pipes & Tubes ( 304)

RATES OF S.S. TUBES 304 PER MTR.

SIZE | O.D. | 10G(3.25) | 12G(2.64) | 14G(2.03) | 16G(1.62) | 18G(1.21) | 20G(0.91) | ||||

IN MM | [0.128"] | [0.104"] | [0.080"] | [0.064"] | [0.048"] | [0.036"] | |||||

| 1/2" | 12.7 | 155 | 138 | 119 | 101 | 79 | 59 | ||||

3/4" | 19.05 | 266 | 224.7 | 184.8 | 155.1 | 116.6 | 89.1 | ||||

1" | 25.4 | 363 | 302.4 | 247.5 | 212.3 | 157.3 | 121 | ||||

1.1/4" | 31.75 | 467 | 389.55 | 315.7 | 264 | 198 | 144.1 | ||||

1.1/2" | 38.1 | 571 | 470.4 | 381.7 | 326.7 | 239.8 | 180.4 | ||||

1.3/4" | 44.45 | 686 | 558.6 | 454.3 | 382.8 | 281.6 | 212.3 | ||||

2" | 50.8 | 760 | 627.9 | 502.7 | 437.8 | 322.3 | 242 | ||||

2.1/2" | 63.5 | 964 | 791.7 | 633.6 | 572 | 405.9 | 0 | ||||

3" | 76.2 | 1167 | 955.5 | 764.5 | 666.6 | 488.4 | 0 | ||||

4" | 101.6 | 1573 | 1290.45 | 1026.3 | 894.3 | 0 | 0 | ||||

5" | 127.0 | 2031 | 1664.25 | 1322.2 | 1178.1 | 0 | 0 | ||||

6" | 152.4 | 2455 | 2004.45 | 1591.7 | 1421.2 | 0 | 0 | ||||

RATES OF S.S. PIPES 304Q PER MTR

MM | INCH | SCH 5 | SCH 10 | SCH 40 |

15 | 1/2" | 175 | 222 | 262 |

20 | 3/4" | 211 | 275 | 341 |

25 | 1" | 262 | 421 | 497 |

32 | 1.1/4" | 334 | 541 | 642 |

40 | 1.1/2" | 385 | 624 | 820 |

50 | 2" | 483 | 798 | 1084 |

65 | 2.1/2" | 778 | 1145 | 1855 |

80 | 3" | 948 | 1406 | 2289 |

100 | 4" | 1225 | 1821 | 3265 |

125 | 5" | 1969 | 2471 | 4719 |

150 | 6" | 2352 | 2925 | 5578 |

200 | 8" | 3072 | 4158 | 8658 |

250 | 10" | 5005 | 6440 | 11277 |

300 | 12" | 6660 | 7616 | 15075 |

350 | 14" | 7865 | 9094 | 18384 |

Rates : Subject to Final Confirmation.

Life time Member of

THE BOMBAY PIPES & FITTINGS MERCHANTۥS ASSOCIATION

-----------------PRICE OF PIPES-------------------------------------

Stainless Steel Pipe

ELIVERY: Ex Stock or 15-30 DAYS or AS COMMUNICATION

Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer)

Port of Dispatch : CST Air Port, Mumbai & Nhava Seva Sea Port

Production Capacity : 500 Metric Tons/Month

AISI 316L Stainless Steel Pipe

AISI 316L stainless steel pipe

ISO9001:2008

1) Diameters: 4 -76.2mm

2) W.T.: 0.4 - 2.5mm

FOB Price: US$1500 to 6900 / Ton

Stainless Steel Pipe, Bright And Annealed, ASTMA249 TP304L

Stainless steel pipe

1. The price is competitive.

2. There is a high quality.

3. Finished Bright and Annealing.

FOB Price: US$2950 to 6750 / Ton

SS Pipe, 4 Inch Seamless Stainless Steel Pipe

Water pipe, seamless stainless steel pipe (ss smls pipe)

1.OD:12-219mm

2.WT:1 to 5mm

3.Standard:GB ASTM

4.Mirror pipe

FOB Price: US$4.62 to 19.5 / Kilogram

COLD DRAWN Seamless Stainless Steel Pipe

stainless steel pipe

grade:TP304(L) TP316(L) TP321

standard: ASTM/GOST/JIS/DIN/BS

certificate:ISO PED

OD:6-600,WT:1-30 L:14M...

FOB Price: US$2500 to 7500 / Ton

Best Quality Grade 201 304 316 430 Stainless Steel Pipe /Tube In India

Quick Details Standard: ASTM Place of Origin: India

Model Number: 17 Type: Seamless Steel Grade: 300 Series

FOB Price: US$1500 to 5500 / Metric Ton

Top Quality Stainless Steel Pipe

stainless steel pipe

1.Material:stainless steel

2.Standards:ASTM,JIS,DIN,GB,SUS

3.Diameter:6mm-610mm

4.Thickness:0.5mm-8mm...

FOB Price: US$1200 to 10000 / Ton

2013 High Quality TP316 316L 321 309 310 310S 304 Stainless Steel Pipe

1) Large Caliber Stainless Steel Pipe

2) O.D: 15-1500mm; W.T: 1-100mm

3) Standard: ASTM/API/DIN/JIS/GB

4) READY STOCK

FOB Price: US$2500 to 6500 / Ton

304 Stainless Steel Pipe

304 Stainless Steel Pipe

1) Grade : 321, 304, 304L, 316, 316L, 317, 317L,310s,904L etc.

2) Standards: GB/ASTM/ASME/DIN/JIS etc

FOB Price: US$1000 to 7000 / Ton

Reduction Sale ! ! ! ASTM 304 Stainless Steel Pipe Of Bottom Price

1.Selected/high quality materials

2.Dimensional accuracy

3.Prime quality & bottom price

4.Strong corrosion resistant...

FOB Price: US$2500 to 5000 / Ton

904L Duplex Stainless Steel Pipe Price

904L duplex stainless steel pipe

1.Grade:201 304 316 316L 310 310S 409 410 430 904

2.Thickness:1mm-150mm

3.Length:1-12m

FOB Price: US$1500 to 7000 / Ton

Sanitary Stainless Steel Pipe

stainless steel pipe

1.Grade 304L/316L/321/310S/347H

2.OD 10mm to 3006mm

3.WT 1mm to 15mm

4.certification:ISO

FOB Price: US$1000 to 7000 / Ton

304 Stainless steel seamless pipe US $2100-2400 / Ton (FOB Price)

316 Stainless steel seamless pipe US $2000-3000 / Ton (FOB Price)

Inconel 625 Plate US $15-45 / Kilogram (FOB Price)

Inconel 825 Flanges US $25-100 / Piece (FOB Price)

ASTM 304 Welding Or Seamless Stainless Steel Pipe/Tube

1).Item:309Stainless Steel

2).PipeStandard:ASTM,JIS,DIN,EN,etc.Wall

3).Thickness:1mm to 150mm Outside

4).Diameter:6mm to 2500mm

FOB Price: US$2890 to 5950 / Ton

304 Stainless Steel Pipes Best Price At Raaj Sagar Steels

best Price at Raaj Sagar Steels for 304 stainless steel pipes

1.outer diameter:6mm-2500mm

2.thickness:0.5mm-150mm

3.length:6m or as you

FOB Price: US$2000 to 7000 / Ton

Welded Stainless Steel Pipe

welded stainless steel pipe

1)Grade:300,600,800series

2)O.D:0.33-300mm; W.T:0.08-6mm

3)Standard:ASTM AISI EN DIN GB

FOB Price: US$10 to 15000 / Ton

Industrial Manufacturing Stainless Steel Pipe 201

Stainless Steel Pipe

1.Material:201,202,304,316L,310,etc

2.OD:6mm-800mm

3 Thickness:0.3-25mm

4 Surface:Mirror,Satin/HL...

FOB Price: US$1500 to 5800 / Metric Ton

How is Stainless Steel Pipe Made | Stainless Steel Pipe and Tube Manufacturing Process

Stainless Steel Pipe and Tube Manufacturing Process

In the nineteenth century, rolling mill technology was the only technique used to manufacture stainless tubes and pipes for industrial purpose. This rolling technique involved long procedures. The rolled strips of sheet were formed into a circular cross section with the help of funnel rolls. The lap welding was then done on these rolled strips through the forge welding process.

Thankfully with the advent of development and technology, various processes came into existence for the manufacturing of stainless tubes and pipes in India. Now-a-days, stainless steel pipes and tubes are manufactured with continuous tube mill using multitorch tungsten Inert gas. The filler metal or forge welding process is not used in this technique.

Stainless Steel Pipe and Tube Manufacturing Process

Tube mill Process description:

- Rolling and welding

Firstly, the stainless steel strips are made to gone through various quality checks and are trimmed at edges. They are then fed to the tubes mill by stainless steel pipe manufacturers in India. The strips pass through the number of rollers as per the required size. In the tubes-mill, the strip is gradually converted into the tubular shape. The fitted welding machine is then used to weld trim edges of the strip using TIG welding process. The scraps and inside weld bead are removed instantaneously by the Tibo machine. In this way, rolled pipes and tubes are formed.

- The cleaning and heating phase

The rolled stainless steel pipes thus manufactured are cut to the required lengths depending upon the industrial demand. These stainless pipes and tubes are then subjected to cleaning to remove the dirt. Further, a heat treatment is given to these rolled pipes and tubes to remove the stresses that may occur due to welding and formation processes. Heat treatment is given on the continuously rolling hearth furnace. The furnace is fitted with temperature recorders and controllers. After the heat treatment process, the SS tubes and pipes are straightened and subjected to pickling for removing scales from the surface.

- Cold- drawing process

In some cases, the required size may not be obtained from the mill directly. Then, the cold operation process can be used to obtain the desired size. In cold drawing process, the tubes or pipes are coated with oxalic and soap solution. This solution acts as a lubricant to reduce friction while cold drawing operation. In the cold drawing process, the tube or pipe is drawn over the bench using Die plugs.

- Finishing process

The drawn-out tube or ss pipe is then subjected to cleaning, heat treatment, pickling and straightening. The computerized ink jet marking machine is used to do the marking on the finished pipes or tubes. The pipe or tube is marked with grade of material, size, heat number and the stamp of third party inspection before passing on to stainless steel pipe exporters. The stainless tubes or pipes thus produced will undergo certain testing and quality checks. This process is followed by proper packing and dispatch. There are numerous numbers of stainless steel pipe applications, these pipes and tubes are used thereafter for.

Raaj Sagar Steels is one of the leading Stainless Steel Pipe manufacturer in India. We provide services to oil and gas, pipeline, food processing, automobile and other manufacturing industries worldwide Our state of art manufacturing unit is capable of producing wide range and dimensions of stainless steel pipe and tube. We supply our customers with the highest level of stainless steel products. We are Stainless steel pipe and tube manufacturer from India.

Steel Pipe History

Steel pipes are long, hollow tubes that are used for a variety of purposes. They are produced by two distinct methods which result in either a welded or seamless pipe. In both methods, raw steel is first cast into a more workable starting form. It is then made into a pipe by stretching the steel out into a seamless tube or forcing the edges together and sealing them with a weld. The first methods for producing steel pipe were introduced in the early 1800s, and they have steadily evolved into the modern processes we use today. Each year, millions of tons of steel pipe are produced. Its versatility makes it the most often used product produced by the steel industry.

Steel pipes are found in a variety of places. Since they are strong, they are used underground for transporting water and gas throughout cities and towns. They are also employed in construction to protect electrical wires. While steel pipes are strong, they can also be lightweight. This makes them perfect for use in bicycle frame manufacture. Other places they find utility is in automobiles, refrigeration units, heating and plumbing systems, flagpoles, street lamps, and medicine to name a few.

History

People have used pipes for thousands of years. Perhaps the first use was by ancient agriculturalists who diverted water from streams and rivers into their fields. Archeological evidence suggests that the Chinese used reed pipe for transporting water to desired locations as early as 2000 B.C. Clay tubes that were used by other ancient civilizations have been discovered. During the first century A.D. , the first lead pipes were constructed in Europe. In tropical countries, bamboo tubes were used to transport water. Colonial Americans used wood for a similar purpose. In 1652, the first waterworks was made in Boston using hollow logs.

Development of the modern day welded steel pipe can be traced back to the early 1800s. In 1815, William Murdock invented a coal burning lamp system. To fit the entire city of London with these lights, Murdock joined together the barrels from discarded muskets. He used this continuous pipeline to transport the coal gas. When his lighting system proved successful a greater demand was created for long metal tubes. To produce enough tubes to meet this demand, a variety of inventors set to work on developing new pipe making processes.

An early notable method for producing metal tubes quickly and inexpensively was patented by James Russell in 1824. In his method, tubes were created by joining together opposite edges of a flat iron strip. The metal was first heated until it was malleable. Using a drop hammer, the edges folded together and welded. The pipe was finished by passing it through a groove and rolling mill.

Russell's method was not used long because in the next year, Comelius Whitehouse developed a better method for making metal tubes. This process, called the butt-weld process is the basis for our current pipe-making procedures. In his method, thin sheets of iron were heated and drawn through a cone-shaped opening. As the metal went through the opening, its edges curled up and created a pipe shape. The two ends were welded together to finish the pipe. The first manufacturing plant to use

Welded pipe is formed by rolling steel strips through a series of grooved rollers that mold the material into a circular shape. Next, the unwelded pipe passes by welding electrodes. These devices seal the two ends of the pipe together. this process in the United States was opened in 1832 in Philadelphia.

Welded pipe is formed by rolling steel strips through a series of grooved rollers that mold the material into a circular shape. Next, the unwelded pipe passes by welding electrodes. These devices seal the two ends of the pipe together. this process in the United States was opened in 1832 in Philadelphia.Gradually, improvements were made in the Whitehouse method. One of the most important innovations was introduced by John Moon in 1911. He suggested the continuous process method in which a manufacturing plant could produce pipe in an unending stream. He built machinery for this specific purpose and many pipe manufacturing facilities adopted it.

While the welded tube processes were being developed, a need for seamless metal pipes arouse. Seamless pipes are those which do not have a welded seam. They were first made by drilling a hole through the center of a solid cylinder. This method was developed during the late 1800s. These types of pipes were perfect for bicycle frames because they have thin walls, are lightweight but are strong. In 1895, the first plant to produce seamless tubes was built. As bicycle manufacturing gave way to auto manufacturing, seamless tubes were still needed for gasoline and oil lines. This demand was made even greater as larger oil deposits were found.

As early as 1840, ironworkers could already produce seamless tubes. In one method, a hole was drilled through a solid metal, round billet. The billet was then heated and drawn through a series of dies which elongated it to form a pipe. This method was inefficient because it was difficult to drill the hole in the center. This resulted in an uneven pipe with one side being thicker than the other. In 1888, an improved method was awarded a patent. In this process the solid billed was cast around a fireproof brick core. When it was cooled, the brick was removed leaving a hole in the middle. Since then new roller techniques have replaced these methods.

Design

There are two types of steel pipe, one is seamless and another has a single welded seam along its length. Both have different uses. Seamless tubes are typically more light weight, and have thinner walls. They are used for bicycles and transporting liquids. Seamed tubes are heavier and more rigid. The have a better consistency and are typically straighter. They are used for things such as gas transportation, electrical conduit and plumbing. Typically, they are used in instances when the pipe is not put under a high degree of stress.

Certain pipe characteristics can be controlled during production. For example, the diameter of the pipe is often modified depending how it will be used. The diameter can range from tiny pipes used to make hypodermic needles, to large pipes used to transport gas throughout a city. The wall thickness of the pipe can also be controlled. Often the type of steel will also have an impact on pipe's the strength and flexibility. Other controllable characteristics include length, coating material, and end finish.

Raw Materials

The primary raw material in pipe production is steel. Steel is made up of primarily iron. Other metals that may be present in the alloy include aluminum, manganese, titanium, tungsten, vanadium, and zirconium. Some finishing materials are sometimes used during production. For example, paint may be

Seamless pipe is manufactured using a process that heats and molds a solid billet into a cylindrical shape and then rolls it until it is stretched and hollowed. Since the hollowed center is irregularly shaped, a bullet-shaped piercer point is pushed through the middle of the billet as it is being rolled.

used if the pipe is coated. Typically, a light amount of oil is applied to steel pipes at the end of the production line. This helps protect the pipe. While it is not actually a part of the finished product, sulfuric acid is used in one manufacturing step to clean the pipe.

The Manufacturing

Process

Steel pipes are made by two different processes. The overall production method for both processes involves three steps. First, raw steel is converted into a more workable form. Next, the pipe is formed on a continuous or semicontinuous production line. Finally, the pipe is cut and modified to meet the customer's needs.

Ingot production

- 1 Molten steel is made by melting iron ore and coke (a carbon-rich substance that results when coal is heated in the absence of air) in a furnace, then removing most of the carbon by blasting oxygen into the liquid. The molten steel is then poured into large, thick-walled iron molds, where it cools into ingots.

- 2 In order to form flat products such as plates and sheets, or long products such as bars and rods, ingots are shaped between large rollers under enormous pressure.

Producing blooms and slabs

- 3 To produce a bloom, the ingot is passed through a pair of grooved steel rollers that are stacked. These types of rollers are called "two-high mills." In some cases, three rollers are used. The rollers are mounted so that their grooves coincide, and they move in opposite directions. This action causes the steel to be squeezed and stretched into thinner, longer pieces. When the rollers are reversed by the human operator, the steel is pulled back through making it thinner and longer. This process is repeated until the steel achieves the desired shape. During this process, machines called manipulators flip the steel so that each side is processed evenly.

- 4 Ingots may also be rolled into slabs in a process that is similar to the bloom making process. The steel is passed through a pair of stacked rollers which stretch it. However, there are also rollers mounted on the side to control the width of the slabs. When the steel acquires the desired shape, the uneven ends are cut off and the slabs or blooms are cut into shorter pieces.

Further processing

- 5 Blooms are typically processed further before they are made into pipes. Blooms are converted into billets by putting them through more rolling devices which make them longer and more narrow. The billets are cut by devices known as flying shears. These are a pair of synchronized shears that race along with the moving billet and cut it. This allows efficient cuts without stopping the manufacturing process. These billets are stacked and will eventually become seamless pipe.

- 6 Slabs are also reworked. To make them malleable, they are first heated to 2,200° F (1,204° C). This causes an oxide coating to form on the surface of the slab. This coating is broken off with a scale breaker and high pressure water spray. The slabs are then sent through a series of rollers on a hot mill and made into thin narrow strips of steel called skelp. This mill can be as long as a half mile. As the slabs pass through the rollers, they become thinner and longer. In the course of about three minutes a single slab can be converted from a 6 in (15.2 cm) thick piece of steel to a thin steel ribbon that can be a quarter mile long.

- 7 After stretching, the steel is pickled. This process involves running it through a series of tanks that contain sulfuric acid to clean the metal. To finish, it is rinsed with cold and hot water, dried and then rolled up on large spools and packaged for transport to a pipe making facility.

Pipe making

- 8 Both skelp and billets are used to make pipes. Skelp is made into welded pipe. It is first placed on an unwinding machine. As the spool of steel is unwound, it is heated. The steel is then passed through a series of grooved rollers. As it passes by, the rollers cause the edges of the skelp to curl together. This forms an unwelded pipe.

- 9 The steel next passes by welding electrodes. These devices seal the two ends of the pipe together. The welded seam is then passed through a high pressure roller which helps create a tight weld. The pipe is then cut to a desired length and stacked for further processing. Welded steel pipe is a continuous process and depending on the size of the pipe, it can be made as fast as 1,100 ft (335.3 m) per minute.

- 10 When seamless pipe is needed, square billets are used for production. They are heated and molded to form a cylinder shape, also called a round. The round is then put in a furnace where it is heated white-hot. The heated round is then rolled with great pressure. This high pressure rolling causes the billet to stretch out and a hole to form in the center. Since this hole is irregularly shaped, a bullet shaped piercer point is pushed through the middle of the billet as it is being rolled. After the piercing stage, the pipe may still be of irregular thickness and shape. To correct this it is passed through another series of rolling mills.

Final processing

- 11 After either type of pipe is made, they may be put through a straightening machine. They may also be fitted with joints so two or more pieces of pipe can be connected. The most common type of joint for pipes with smaller diameters is threading—tight grooves that are cut into the end of the pipe. The pipes are also sent through a measuring machine. This information along with other quality control data is automatically stenciled on the pipe. The pipe is then sprayed with a light coating of protective oil. Most pipe is typically treated to prevent it from rusting. This is done by galvanizing it or giving it a coating of zinc. Depending on the use of the pipe, other paints or coatings may be used.

Quality Control

A variety of measures are taken to ensure that the finished steel pipe meets specifications. For example, x-ray gauges are used to regulate the thickness of the steel. The gauges work by utilizing two x rays. One ray is directed at a steel of known thickness. The other is directed at the passing steel on the production line. If there is any variance between the two rays, the gauge will automatically trigger a resizing of the rollers to compensate.

Pipes are also inspected for defects at the end of the process. One method of testing a pipe is by using a special machine. This machine fills the pipe with water and then increases the pressure to see if it holds. Defective pipes are returned for scrap.

If you don’t see what you’re looking for just call one of our team members at +91-22-6659 5285 Or Mail Us inquiry@raajsagarsteels.com. No inquiry is too large or too small, we specialize in locating hard to find items. If you do see what you are looking, we would love to assist you and give you a quote today!

24 Hrs. Online Whatsapp Number Contact Person: Mr. Milap Mehta - Cell: +91-9869 532 584