Asme Din Iso Fasteners Specification

Asme Din Iso Fasteners Specification / Threaded Insert / Diameter / UNF / UNC

Table of Content

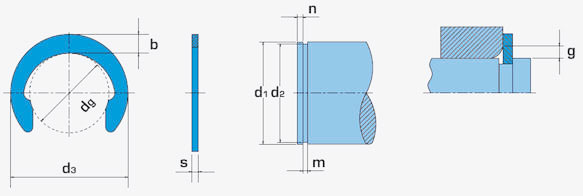

Crescent Ring for Shafts Series 2103 – 5103 Specifications

Recommended Tapping Drill Size - ISO Metric Coarse

Recommended Tapping Drill Size - ISO Metric Fine

Recommended Tapping Drill Size - UNC

Recommended Tapping Drill Size - UNF

Threaded Insert Fitted (Metric)

Threaded Insert Nominal Length (Metric)

Threaded Insert Drilling Depth (Metric)

Fasteners Mechanical Properties Dimensions

Mechanical Properties for Socket Products - DIN 912 Socket Cap Screws

Mechanical Properties for Socket Products - ASME B18.3 Socket Cap Screws

Mechanical Properties for Socket Products - DIN 7984 Low Head Socket Caps

Mechanical Properties for Socket Products - ASME B18.3 Low Head Socket Caps

Mechanical Properties for Socket Products - DIN 7991 Flat Head Countersunk Socket Cap Screws

Mechanical Properties for Socket Products - ASME B18.3 Flat Head Countersunk Socket Cap Screws

Mechanical Properties for Socket Products - ISO 7380 Button Head Socket Cap Screws

Mechanical Properties for Socket Products - ASME B18.3 Button Head Socket Cap Screws

Mechanical Properties for Socket Products - ISO 7379 Socket Shoulder Screws

Mechanical Properties for Socket Products - ASME B18.3 Socket Shoulder Screws

Mechanical Properties for Socket Products - DIN 916 Set Screws

Mechanical Properties for Socket Products - ASME B18.3 Set Screws

Mechanical Properties for Hex Products - ISO 4014 / 4017 Hex Head Bolts

Mechanical Properties for Hex Products - ASME B18.2.1 Hexagon Head Cap Screws

Mechanical Properties for Hex Products - ISO 4162 Hexagon Flange Bolts

Mechanical Properties for Hex Products - IFI-111 Hexagon Flange Screws

External Inverted Ring Specifications

Platings and Finishes Dimensions

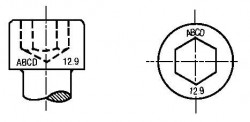

Grade Markings for Metric Fasteners - Marking Of Nuts

Fastener Finish K Factors

Steels generally used for metric screws, bolts and studs

Standard / Metric Conversion Tables

Weights for DIN 472

Screw Thread Conversions - MAJOR DIAMETER (Converted to INCH Decimals)

Screw Thread Conversions - THREAD PITCH (Converted to Number of Threads per Inch)

Weights for DIN 1652

Threaded Insert Nominal Length (UNC)

Threaded Insert Fitted (UNC)

Threaded Insert Fitted (UNF)

ISO Tolerances

Retaining Ring Interchange Chart

Basic Metric Thread Chart (M1 – M100)

Specifications for Drill Rod

Threaded Insert Outer Diameter In The Free State (UNC)

Threaded Insert Outer Diameter In The Free State (UNF)

Threaded Insert Number Of Coils In The Free State (UNF)

Threaded Insert Number Of Coils In The Free State (Metric)

Threaded Insert Number Of Coils In The Free State (UNC)

Fasteners Threaded Insert Nominal Length (UNF) Dimensions

DIN 1480 Turnbuckle Dimensions

Threaded Insert Drilling Depth (UNC)

Threaded Insert Drilling Depth (UNF)

Fasteners Crescent Ring for Shafts Series 2103 – 5103 Specifications Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Crescent Ring for Shafts Series 2103 – 5103 Specifications

Crescent Ring for Shafts Series 2103 – 5103 Specifications

All measurements in millimeters (mm)

| Ring n° | d2 | d3 ref. | s | dg | b | d1 | m | n min. | FN Lbr. | Fs Lbr. | g | Fsg Lib. | nabl min. | lbs | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 12 | 0.106 | +0.0015 | 0.165 | 0.015 | +0.002 | 0.102 | +0.002 | 0.031 | +0.003 | 0.125 | 0.020 | +0.002 | 0.020 | 45 | 86 | 0.011 | 85 | 80000 | 0.033 |

| -0.0015 | -0.002 | -0.004 | -0.003 | -0.000 | |||||||||||||||

| 15 | 0.135 | +0.0015 | 0.205 | 0.015 | +0.002 | 0.131 | +0.002 | 0.037 | +0.003 | 0.156 | 0.020 | +0.002 | 0.020 | 55 | 102 | 0.014 | 100 | 75000 | 0.053 |

| -0.0015 | -0.002 | -0.004 | -0.003 | -0.000 | |||||||||||||||

| 18 | 0.165 | +0.0015 | 0.244 | 0.015 | +0.002 | 0.161 | +0.002 | 0.042 | +0.003 | 0.188 | 0.020 | +0.002 | 0.022 | 70 | 132 | 0.016 | 110 | 73000 | 0.070 |

| -0.0015 | -0.002 | -0.004 | -0.003 | -0.000 | |||||||||||||||

| 21 | 0.193 | +0.0020 | 0.275 | 0.025 | +0.002 | 0.187 | +0.003 | 0.044 | +0.003 | 0.219 | 0.029 | +0.003 | 0.026 | 100 | 264 | 0.016 | 260 | 71000 | 0.132 |

| -0.0020 | -0.002 | -0.005 | -0.003 | -0.000 | |||||||||||||||

| 23 | 0.208 | +0.0020 | 0.295 | 0.025 | +0.002 | 0.203 | +0.003 | 0.046 | +0.004 | 0.236 | 0.029 | +0.003 | 0.028 | 115 | 284 | 0.017 | 275 | 62000 | 0.154 |

| -0.0020 | -0.002 | -0.005 | -0.004 | -0.000 | |||||||||||||||

| 25 | 0.220 | +0.0020 | 0.311 | 0.025 | +0.002 | 0.211 | +0.003 | 0.050 | +0.004 | 0.250 | 0.029 | +0.003 | 0.030 | 130 | 294 | 0.018 | 290 | 60000 | 0.183 |

| -0.0020 | -0.002 | -0.005 | -0.004 | -0.000 | |||||||||||||||

| 28 | 0.247 | +0.0020 | 0.346 | 0.025 | +0.002 | 0.242 | +0.003 | 0.051 | +0.004 | 0.281 | 0.029 | +0.003 | 0.034 | 165 | 335 | 0.016 | 310 | 56000 | 0.176 |

| -0.0020 | -0.002 | -0.005 | -0.004 | -0.000 | |||||||||||||||

| 31 | 0.276 | +0.0020 | 0.376 | 0.025 | +0.002 | 0.270 | +0.003 | 0.053 | +0.004 | 0.312 | 0.029 | +0.003 | 0.036 | 200 | 376 | 0.018 | 310 | 52000 | 0.264 |

| -0.0020 | -0.002 | -0.005 | -0.004 | -0.000 | |||||||||||||||

| 37 | 0.335 | +0.0020 | 0.448 | 0.025 | +0.002 | 0.328 | +0.003 | 0.060 | +0.004 | 0.375 | 0.029 | +0.003 | 0.040 | 270 | 447 | 0.020 | 310 | 43000 | 0.297 |

| -0.0020 | -0.002 | -0.005 | -0.004 | -0.000 | |||||||||||||||

| 40 | 0.364 | +0.0020 | 0.486 | 0.025 | +0.002 | 0.359 | +0.003 | 0.063 | +0.004 | 0.406 | 0.029 | +0.003 | 0.042 | 300 | 487 | 0.021 | 310 | 40000 | 0.374 |

| -0.0020 | -0.002 | -0.005 | -0.004 | -0.000 | |||||||||||||||

| 43 | 0.393 | +0.0020 | 0.517 | 0.025 | +0.002 | 0.386 | +0.003 | 0.065 | +0.004 | 0.438 | 0.029 | +0.003 | 0.044 | 350 | 528 | 0.022 | 310 | 31000 | 0.352 |

| -0.0020 | -0.002 | -0.005 | -0.004 | -0.000 | |||||||||||||||

| 50 | 0.450 | +0.0030 | 0.581 | 0.035 | +0.002 | 0.441 | +0.006 | 0.070 | +0.005 | 0.500 | 0.039 | +0.003 | 0.050 | 450 | 842 | 0.023 | 610 | 25000 | 0.733 |

| -0.0030 | -0.002 | -0.006 | -0.005 | -0.000 | |||||||||||||||

| 56 | 0.507 | +0.0030 | 0.653 | 0.035 | +0.002 | 0.497 | +0.006 | 0.078 | +0.005 | 0.562 | 0.039 | +0.003 | 0.056 | 550 | 944 | 0.025 | 610 | 22000 | 0.836 |

| -0.0030 | -0.002 | -0.006 | -0.005 | -0.000 | |||||||||||||||

| 62 | 0.563 | +0.0030 | 0.715 | 0.035 | +0.002 | 0.553 | +0.006 | 0.081 | +0.005 | 0.625 | 0.039 | +0.003 | 0.062 | 700 | 1045 | 0.025 | 610 | 20000 | 0.946 |

| -0.0030 | -0.002 | -0.006 | -0.005 | -0.000 | |||||||||||||||

| 68 | 0.619 | +0.0030 | 0.784 | 0.042 | +0.002 | 0.608 | +0.007 | 0.086 | +0.005 | 0.688 | 0.046 | +0.003 | 0.068 | 800 | 1726 | 0.026 | 880 | 18500 | 1.320 |

| -0.0030 | -0.002 | -0.007 | -0.005 | -0.000 | |||||||||||||||

| 75 | 0.676 | +0.0030 | 0.845 | 0.042 | +0.002 | 0.665 | +0.007 | 0.090 | +0.005 | 0.750 | 0.046 | +0.003 | 0.074 | 1000 | 1878 | 0.027 | 880 | 17500 | 1.496 |

| -0.0030 | -0.002 | -0.007 | -0.005 | -0.000 | |||||||||||||||

| 81 | 0.732 | +0.0030 | 0.915 | 0.042 | +0.002 | 0.721 | +0.007 | 0.097 | +0.005 | 0.812 | 0.046 | +0.003 | 0.080 | 1150 | 2040 | 0.029 | 880 | 16000 | 1.716 |

| -0.0030 | -0.002 | -0.007 | -0.005 | -0.000 | |||||||||||||||

LINKS HERE

*All information is strictly informative

Fasteners ISO Metric Coarse Recommended Tapping Drill Size Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners ISO Metric Coarse Recommended Tapping Drill Size / Fasteners ISO Metric Coarse Recommended Tapping Drill SizeFasteners ISO Metric Coarse Recommended Tapping Drill Size Dimensions, Weight Chart & Material Specification & Tolerances

Recommended Tapping Drill Size

ISO Metric Coarse

| Size (mm) | Pitch (mm) | Drill (mm) |

|---|---|---|

| M1 | .25 | .75 |

| M1.1 | .25 | .85 |

| M1.2 | .25 | .95 |

| M1.4 | .3 | 1.1 |

| M1.6 | .35 | 1.25 |

| M1.8 | .35 | 1.45 |

| M2 | .4 | 1.6 |

| M2.2 | .45 | 1.75 |

| M2.5 | .45 | 2.05 |

| M3 | .5 | 2.5 |

| M3.5 | .6 | 2.9 |

| M4 | .7 | 3.3 |

| M4.5 | .75 | 3.75 |

| M5 | .8 | 4.2 |

| M6 | 1 | 5 |

| M7 | 1 | 6 |

| M8 | 1.25 | 6.75 |

| M9 | 1.25 | 7.75 |

| M10 | 1.5 | 8.5 |

| M11 | 1.5 | 9.5 |

| M12 | 1.75 | 10.2 |

| M14 | 2 | 12 |

| M16 | 2 | 14 |

| M18 | 2.5 | 15.5 |

| M20 | 2.5 | 17.5 |

| M22 | 2.5 | 19.5 |

| M24 | 3 | 21 |

| M27 | 3 | 24 |

| M30 | 3.5 | 26.5 |

| M33 | 3.5 | 29.5 |

| M36 | 4 | 32 |

| M39 | 4 | 35 |

| M42 | 4.5 | 37.5 |

| M45 | 4.5 | 40.5 |

| M48 | 5 | 43 |

| M52 | 5 | 47 |

| M56 | 5.5 | 50.5 |

| M60 | 5.5 | 54.5 |

| M64 | 6 | 58 |

| M68 | 6 | 62 |

| M72 | 6 | 66 |

| M76 | 6 | 70 |

| Size (mm) | Pitch (mm) | Drill (mm) |

|---|---|---|

| M2 | .25 | 1.75 |

| M2.2 | .25 | 1.95 |

| M2.3 | .25 | 2.05 |

| M2.5 | .35 | 2.15 |

| M2.6 | .35 | 2.25 |

| M3 | .35 | 2.65 |

| M3.5 | .35 | 3.15 |

| M4 | .35 | 3.65 |

| M4 | .5 | 3.5 |

| M5 | .35 | 4.65 |

| M5 | .5 | 4.5 |

| M5 | .75 | 4.25 |

| M5.5 | .5 | 5 |

| M6 | .5 | 5.5 |

| M6 | .75 | 5.25 |

| M7 | .75 | 6.25 |

| M8 | .5 | 7.5 |

| M8 | .75 | 7.25 |

| M8 | 1 | 7 |

| M9 | .75 | 8.25 |

| M9 | 1 | 8 |

| M10 | .5 | 9.5 |

| M10 | .75 | 9.25 |

| M10 | 1 | 9 |

| M10 | 1.25 | 8.75 |

| M11 | .75 | 10.25 |

| M11 | 1 | 10 |

| M11 | 1.25 | 9.75 |

| M12 | .5 | 11.5 |

| M12 | .75 | 11.25 |

| M12 | 1 | 11 |

| M12 | 1.25 | 10.75 |

| M12 | 1.5 | 10.5 |

| M14 | 1 | 13 |

| M14 | 1.25 | 12.75 |

| M14 | 1.5 | 12.5 |

| M15 | .75 | 14.25 |

| M15 | 1 | 14 |

| M15 | 1.5 | 13.5 |

| M16 | .5 | 15.5 |

| M16 | .75 | 15.25 |

| M16 | 1 | 15 |

| M16 | 1.25 | 14.75 |

| M16 | 1.5 | 14.5 |

| M17 | 1 | 16 |

| M17 | 1.5 | 15.5 |

| M18 | .75 | 17.25 |

| M18 | 1 | 17 |

| M18 | 1.25 | 16.75 |

| M18 | 1.5 | 16.5 |

| M18 | 2 | 16 |

| M19 | 1 | 18 |

| M20 | 1 | 19 |

| M20 | 1.5 | 18.5 |

| M20 | 2 | 18 |

| M22 | 1 | 21 |

| M22 | 1.5 | 20.5 |

| M22 | 2 | 20 |

| M24 | 1 | 23 |

| M24 | 1.5 | 22.5 |

| M24 | 2 | 22 |

| M25 | 1 | 24 |

| M25 | 1.5 | 23.5 |

| M25 | 2 | 23 |

| M27 | 1 | 26 |

| M27 | 1.5 | 25.5 |

| M27 | 2 | 25 |

| M28 | 1 | 27 |

| M28 | 1.5 | 26.5 |

| M28 | 2 | 26 |

| M30 | 1 | 29 |

| M30 | 1.5 | 28.5 |

| M30 | 2 | 28 |

| M30 | 3 | 27 |

| M32 | 1 | 31 |

| M32 | 1.5 | 30.5 |

| M32 | 2 | 30 |

| M33 | 1.5 | 31.5 |

| M33 | 2 | 31 |

| M33 | 3 | 30 |

| M35 | 1.5 | 33.5 |

| M35 | 2 | 33 |

| M35 | 3 | 32 |

| M36 | 1 | 35 |

| M36 | 1.5 | 34.4 |

| M36 | 2 | 34 |

| M36 | 3 | 33 |

| M38 | 1 | 37 |

| M38 | 1.5 | 36.5 |

| M38 | 2 | 36 |

| M39 | 1.5 | 37.5 |

| M39 | 2 | 37 |

| M39 | 3 | 36 |

| M40 | 1 | 39 |

| M40 | 1.5 | 38.5 |

| M40 | 3 | 37 |

| M42 | 1.5 | 40.5 |

| M42 | 2 | 40 |

| M42 | 3 | 39 |

| M42 | 4 | 38 |

| M45 | 1.5 | 43.5 |

| M45 | 2 | 43 |

| M45 | 3 | 42 |

| M48 | 1.5 | 46.5 |

| M48 | 2 | 46 |

| M48 | 3 | 45 |

| M48 | 4 | 44 |

| M50 | 1.5 | 48.5 |

| M50 | 2 | 48 |

| M50 | 3 | 47 |

| M52 | 1.5 | 50.5 |

| M52 | 2 | 50 |

| M52 | 3 | 49 |

| M52 | 4 | 48 |

| M56 | 2 | 54 |

| M56 | 4 | 52 |

| Size No. or inch | Pitch TPI | Drill (mm) |

|---|---|---|

| #1 | 64 | 1.55 |

| #2 | 56 | 1.85 |

| #3 | 48 | 2.1 |

| #4 | 40 | 2.35 |

| #5 | 40 | 2.65 |

| #6 | 32 | 2.85 |

| #8 | 32 | 3.5 |

| #10 | 24 | 3.9 |

| #12 | 24 | 4.5 |

| 1/4 | 20 | 5.1 |

| 5/16 | 18 | 6.6 |

| 3/8 | 16 | 8 |

| 7/16 | 14 | 9.4 |

| 1/2 | 13 | 10.8 |

| 9/16 | 12 | 12.2 |

| 5/8 | 11 | 13.5 |

| 3/4 | 10 | 16.5 |

| 7/8 | 9 | 19.5 |

| 1 | 8 | 22.25 |

| 1 1/8 | 7 | 25 |

| 1 1/4 | 7 | 28 |

| 1 3/8 | 6 | 30.75 |

| 1 1/2 | 6 | 34 |

| 1 3/4 | 5 | 39.5 |

| 2 | 4.5 | 45 |

| 2 1/4 | 4.5 | 51.5 |

| 2 1/2 | 4 | 57.25 |

| 2 3/4 | 4 | 63.5 |

| 3 | 4 | 70 |

| Size No. or inch | Pitch TPI | Drill (mm) |

|---|---|---|

| #0 | 80 | 1.25 |

| #1 | 72 | 1.55 |

| #2 | 64 | 1.9 |

| #3 | 56 | 2.15 |

| #4 | 48 | 2.4 |

| #5 | 44 | 2.7 |

| #6 | 40 | 2.95 |

| #8 | 36 | 3.5 |

| #10 | 32 | 4.1 |

| #12 | 28 | 4.7 |

| 1/4 | 28 | 5.5 |

| 5/16 | 24 | 6.9 |

| 3/8 | 24 | 8.5 |

| 7/16 | 20 | 9.9 |

| 1/2 | 20 | 11.5 |

| 9/16 | 18 | 12.9 |

| 5/8 | 18 | 14.5 |

| 3/4 | 16 | 17.5 |

| 7/8 | 14 | 20.4 |

| 1 | 12 | 23.25 |

| 1 1/8 | 12 | 26.5 |

| 1 1/4 | 12 | 29.5 |

| 1 3/8 | 12 | 32.75 |

| 1 1/2 | 12 | 36 |

*All information is strictly informative

Fasteners Threaded Insert Fitted (Metric) Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Threaded Insert Fitted (Metric) / Fasteners Threaded Insert Fitted (Metric)Fasteners Threaded Insert Fitted (Metric) Dimensions, Weight Chart & Material Specification & Tolerances

Threaded Insert Fitted (Metric)

| Nominal Diameter | Pitch (mm) | Drill Bit Diameter (mm) | Drilling Diameter | Tap | Insert Fitted | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | Min Outer Diameter | 0.5d | 0.75d | 1d | 1.5d | 2d | 2.5d | 3d | |||

| M2 | 0.4 | 2.1 | 2.09 | 2.18 | 2.52 | – | – | 1.6 | 2.6 | 3.6 | 4.6 | 5.6 |

| M2.5 | 0.45 | 2.6 | 2.60 | 2.70 | 3.08 | – | – | 2.1 | 3.3 | 4.6 | 5.8 | 7.1 |

| M3 | 0.5 | 3.2 | 3.11 | 3.22 | 3.65 | – | – | 2.5 | 4.0 | 5.5 | 7.0 | 8.5 |

| M3.5 | 0.6 | 3.7 | 3.63 | 3.76 | 4.28 | – | – | 2.9 | 4.7 | 6.4 | 8.2 | 9.9 |

| M4 | 0.7 | 4.2 | 4.15 | 4.29 | 4.91 | – | – | 3.3 | 5.3 | 7.3 | 9.3 | 11.3 |

| M5 | 0.8 | 5.2 | 5.17 | 5.33 | 6.04 | – | – | 4.2 | 6.7 | 9.2 | 11.7 | 14.2 |

| M6 | 1.0 | 6.3 | 6.22 | 6.41 | 7.30 | – | – | 5.0 | 8.0 | 11.0 | 14.0 | 17.0 |

| M7 | 1.0 | 7.3 | 7.22 | 7.41 | 8.30 | – | – | 6.0 | 9.5 | 13.0 | 16.5 | 20.0 |

| M8x1 | 1.0 | 8.3 | 8.22 | 8.41 | 9.30 | – | – | 7.0 | 11.0 | 15.0 | 19.0 | 23.0 |

| M8 | 1.25 | 8.4 | 8.27 | 8.48 | 9.62 | – | – | 6.8 | 10.8 | 14.8 | 18.8 | 22.8 |

| M9 | 1.25 | 9.4 | 9.27 | 9.48 | 10.62 | – | – | 7.8 | 12.3 | 16.8 | 21.3 | 25.8 |

| M10x1 | 1.0 | 10.25 | 10.22 | 10.41 | 11.30 | – | – | 9.0 | 14.0 | 19.0 | 24.0 | 29.0 |

| M10x1.25 | 1.25 | 10.4 | 10.27 | 10.48 | 11.62 | – | – | 8.8 | 13.8 | 18.8 | 23.8 | 28.8 |

| M10 | 1.5 | 10.5 | 10.32 | 10.56 | 11.95 | – | – | 8.5 | 13.5 | 18.5 | 23.5 | 28.5 |

| M11 | 1.5 | 11.5 | 11.32 | 11.56 | 12.95 | – | – | 9.5 | 15.0 | 20.5 | 26.0 | 31.5 |

| M12x1 | 1.0 | 12.3 | 12.22 | 12.41 | 13.30 | – | – | 11.0 | 17.0 | 23.0 | 29.0 | 35.0 |

| M12x1.25 | 1.25 | 12.4 | 12.27 | 12.48 | 13.62 | – | – | 10.8 | 16.8 | 22.8 | 28.8 | 34.8 |

| M12x1.5 | 1.5 | 12.5 | 12.32 | 12.56 | 13.95 | – | – | 10.5 | 16.5 | 22.5 | 28.5 | 34.5 |

| M12 | 1.75 | 12.5 | 12.38 | 12.64 | 14.27 | – | – | 10.3 | 16.3 | 22.3 | 28.3 | 34.3 |

| M14x1.25 | 1.25 | 14.4 | 14.27 | 14.48 | 15.62 | 5.8 | 9.3 | 12.8 | 19.8 | 26.8 | 33.8 | 40.8 |

| M14x1.5 | 1.5 | 14.5 | 14.32 | 14.56 | 15.95 | – | 9.0 | 12.5 | 19.5 | 26.5 | 33.5 | 40.5 |

| M14 | 2.0 | 14.5 | 14.43 | 14.73 | 16.60 | – | – | 12.0 | 19.0 | 26.0 | 33.0 | 40.0 |

| M16x1.5 | 1.5 | 16.5 | 16.32 | 16.56 | 17.95 | – | 10.5 | 14.5 | 22.5 | 30.5 | 38.5 | – |

| M16 | 2.0 | 16.5 | 16.43 | 16.73 | 18.60 | – | – | 14.0 | 22.0 | 30.0 | 38.0 | 46.0 |

| M18x1.5 | 1.5 | 18.5 | 18.32 | 18.56 | 19.95 | 7.5 | 12.0 | 16.5 | 25.5 | 34.5 | – | – |

| M18x2 | 2.0 | 18.5 | 18.43 | 18.73 | 20.60 | 7.0 | 11.5 | 16.0 | 25.0 | 34.0 | 43.0 | 52.0 |

| M18 | 2.5 | 18.75 | 18.54 | 18.90 | 21.25 | 6.5 | 11.0 | 15.5 | 24.5 | 33.5 | 42.5 | 51.5 |

| M20x1.5 | 1.5 | 20.5 | 20.32 | 20.56 | 21.95 | 8.5 | 13.5 | 18.5 | 28.5 | 38.5 | – | – |

| M20x2 | 2.0 | 20.5 | 20.43 | 20.73 | 22.60 | 8.0 | 13.0 | 18.0 | 28.0 | 38.0 | – | – |

| M20 | 2.5 | 20.75 | 20.54 | 20.90 | 23.25 | 7.5 | 12.5 | 17.5 | 27.5 | 37.5 | 47.5 | 57.5 |

| M22x1.5 | 1.5 | 22.5 | 22.32 | 22.56 | 23.95 | 9.5 | 15.0 | 20.5 | 31.5 | 42.5 | – | – |

| M22x2 | 2.0 | 22.5 | 22.43 | 22.73 | 24.60 | 9.0 | 14.5 | 20.0 | 31.0 | 42.0 | – | – |

| M22 | 2.5 | 22.75 | 22.54 | 22.90 | 25.25 | 8.5 | 14.0 | 19.5 | 30.5 | 41.5 | 52.2 | – |

| M24x1.5 | 1.5 | 24.5 | 24.32 | 24.56 | 25.95 | 10.5 | 16.5 | 22.5 | 34.5 | 46.5 | – | – |

| M24x2 | 2.0 | 24.5 | 24.43 | 24.73 | 26.60 | 10.0 | 16.0 | 22.0 | 34.0 | 46.0 | – | – |

| M24 | 3.0 | 24.75 | 24.65 | 25.05 | 27.90 | 9.0 | 15.0 | 21.0 | 33.0 | 45.0 | 57.0 | – |

| M26x1.5 | 1.5 | 26.5 | 26.32 | 26.56 | 27.95 | 11.5 | 18.0 | 24.5 | 37.5 | 50.5 | – | – |

| M27x1.5 | 1.5 | 27.5 | 27.32 | 27.56 | 28.95 | 12.0 | 18.8 | 25.5 | 39.0 | 52.5 | – | – |

| M27x2 | 2.0 | 27.5 | 27.43 | 27.73 | 29.60 | 11.5 | 18.3 | 25.0 | 38.5 | 52.0 | – | – |

| M27 | 3.0 | 27.75 | 27.65 | 28.05 | 30.90 | 10.5 | 17.3 | 24.0 | 37.5 | 51.0 | – | – |

| M28x1.5 | 1.5 | 28.5 | 28.32 | 28.56 | 29.95 | 12.5 | 19.5 | 26.5 | 40.5 | 54.5 | – | – |

| M30x1.5 | 1.5 | 30.5 | 30.22 | 30.56 | 31.95 | 13.5 | 21.0 | 28.5 | 43.5 | 58.5 | – | – |

| M30x2 | 2.0 | 30.5 | 30.43 | 30.73 | 32.60 | 13.0 | 20.5 | 28.0 | 43.0 | 58.0 | – | – |

| M30 | 3.5 | 31.0 | 30.76 | 31.21 | 34.55 | 11.5 | 19.0 | 26.5 | 41.5 | 56.5 | – | – |

| M33x2 | 2.0 | 33.5 | 33.43 | 33.73 | 35.60 | 14.5 | 22.8 | 31.0 | 47.5 | 64.0 | – | – |

| M33 | 3.5 | 34.0 | 33.76 | 34.21 | 37.55 | 13.0 | 21.3 | 29.5 | 46.0 | 62.5 | – | – |

| M34x1.5 | 1.5 | 34.5 | 34.32 | 34.56 | 35.95 | 15.5 | 24.0 | 32.5 | 49.5 | 66.5 | – | – |

| M36x1.5 | 1.5 | 36.5 | 36.32 | 36.56 | 37.95 | 16.5 | 25.5 | 34.5 | 52.5 | 70.5 | – | – |

| M36x2 | 2.0 | 36.5 | 36.43 | 36.73 | 38.60 | 16.0 | 25.0 | 34.0 | 52.0 | 70.0 | – | – |

| M36x3 | 3.0 | 37.0 | 36.65 | 37.05 | 39.90 | 15.0 | 24.0 | 33.0 | 51.0 | 69.0 | – | – |

| M36 | 4.0 | 37.0 | 36.87 | 37.34 | 41.20 | 14.0 | 23.0 | 32.0 | 50.0 | 68.0 | – | – |

| M39x3 | 3.0 | 40.0 | 39.65 | 40.05 | 42.90 | 16.5 | 26.3 | 36.0 | 55.5 | 75.0 | – | – |

| M39 | 4.0 | 40.0 | 39.87 | 40.34 | 44.20 | – | 25.3 | 35.0 | 54.5 | 74.0 | – | – |

| M42x3 | 3.0 | 43.0 | 42.65 | 43.05 | 45.90 | 18.0 | 28.5 | 39.0 | 60.0 | 81.0 | – | – |

| M42 | 4.5 | 43.0 | 42.98 | 43.50 | 47.85 | – | 27.0 | 37.5 | 58.5 | 79.5 | – | – |

| M45x3 | 3.0 | 46.0 | 45.65 | 46.05 | 48.90 | 19.5 | 30.8 | 42.0 | 64.5 | 87.0 | – | – |

| M45 | 4.5 | 46.0 | 45.98 | 46.50 | 50.85 | – | 29.5 | 40.5 | 63.0 | 85.5 | – | – |

*All information is strictly informative

Threaded Insert Nominal Length (Metric) Dimensions, Weight Chart & Material Specification & TolerancesThreaded Insert Nominal Length (Metric) / Threaded Insert Nominal Length (Metric)Threaded Insert Nominal Length (Metric) Dimensions, Weight Chart & Material Specification & Tolerances

Threaded Insert Nominal Length (Metric)

| Nominal Diameter | Pitch (mm) | Drill Bit Diameter (mm) | Drilling Diameter | Tap | Nominal Length | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | Min Outer Diameter | 0.5d | 0.75d | 1d | 1.5d | 2d | 2.5d | 3d | |||

| M2 | 0.4 | 2.1 | 2.09 | 2.18 | 2.52 | – | – | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 |

| M2.5 | 0.45 | 2.6 | 2.60 | 2.70 | 3.08 | – | – | 2.5 | 3.75 | 5.0 | 6.25 | 7.5 |

| M3 | 0.5 | 3.2 | 3.11 | 3.22 | 3.65 | – | – | 3.0 | 4.5 | 6.0 | 7.5 | 9.0 |

| M3.5 | 0.6 | 3.7 | 3.63 | 3.76 | 4.28 | – | – | 3.5 | 5.25 | 7.0 | 8.75 | 10.5 |

| M4 | 0.7 | 4.2 | 4.15 | 4.29 | 4.91 | – | – | 4.0 | 6.0 | 8.0 | 10.0 | 12.0 |

| M5 | 0.8 | 5.2 | 5.17 | 5.33 | 6.04 | – | – | 5.0 | 7.5 | 10.0 | 12.5 | 15.0 |

| M6 | 1.0 | 6.3 | 6.22 | 6.41 | 7.30 | – | – | 6.0 | 9.0 | 12.0 | 15.0 | 18.0 |

| M7 | 1.0 | 7.3 | 7.22 | 7.41 | 8.30 | – | – | 7.0 | 10.5 | 14.0 | 17.5 | 21.0 |

| M8x1 | 1.0 | 8.3 | 8.22 | 8.41 | 9.30 | – | – | 8.0 | 12.0 | 16.0 | 20.0 | 24.0 |

| M8 | 1.25 | 8.4 | 8.27 | 8.48 | 9.62 | – | – | 8.0 | 12.0 | 16.0 | 20.0 | 24.0 |

| M9 | 1.25 | 9.4 | 9.27 | 9.48 | 10.62 | – | – | 9.0 | 13.5 | 18.0 | 22.5 | 27.0 |

| M10x1 | 1.0 | 10.25 | 10.22 | 10.41 | 11.30 | – | – | 10.0 | 15.0 | 20.0 | 25.0 | 30.0 |

| M10x1.25 | 1.25 | 10.4 | 10.27 | 10.48 | 11.62 | – | – | 10.0 | 15.0 | 20.0 | 25.0 | 30.0 |

| M10 | 1.5 | 10.5 | 10.32 | 10.56 | 11.95 | – | – | 10.0 | 15.0 | 20.0 | 25.0 | 30.0 |

| M11 | 1.5 | 11.5 | 11.32 | 11.56 | 12.95 | – | – | 11.0 | 16.5 | 22.0 | 27.5 | 33.0 |

| M12x1 | 1.0 | 12.3 | 12.22 | 12.41 | 13.30 | – | – | 12.0 | 18.0 | 24.0 | 30.0 | 36.0 |

| M12x1.25 | 1.25 | 12.4 | 12.27 | 12.48 | 13.62 | – | – | 12.0 | 18.0 | 24.0 | 30.0 | 36.0 |

| M12x1.5 | 1.5 | 12.5 | 12.32 | 12.56 | 13.95 | – | – | 12.0 | 18.0 | 24.0 | 30.0 | 36.0 |

| M12 | 1.75 | 12.5 | 12.38 | 12.64 | 14.27 | – | – | 12.0 | 18.0 | 24.0 | 30.0 | 36.0 |

| M14x1.25 | 1.25 | 14.4 | 14.27 | 14.48 | 15.62 | 7.0 | 10.5 | 14.0 | 21.0 | 28.0 | 35.0 | 42.0 |

| M14x1.5 | 1.5 | 14.5 | 14.32 | 14.56 | 15.95 | – | 10.5 | 14.0 | 21.0 | 28.0 | 35.0 | 42.0 |

| M14 | 2.0 | 14.5 | 14.43 | 14.73 | 16.60 | – | – | 14.0 | 21.0 | 28.0 | 35.0 | 42.0 |

| M16x1.5 | 1.5 | 16.5 | 16.32 | 16.56 | 17.95 | – | 12.0 | 16.0 | 24.0 | 32.0 | 40.0 | – |

| M16 | 2.0 | 16.5 | 16.43 | 16.73 | 18.60 | – | – | 16.0 | 24.0 | 32.0 | 40.0 | 48.0 |

| M18x1.5 | 1.5 | 18.5 | 18.32 | 18.56 | 19.95 | 9.0 | 13.5 | 18.0 | 27.0 | 36.0 | – | – |

| M18x2 | 2.0 | 18.5 | 18.43 | 18.73 | 20.60 | 9.0 | 13.5 | 18.0 | 27.0 | 36.0 | 45.0 | 54.0 |

| M18 | 2.5 | 18.75 | 18.54 | 18.90 | 21.25 | 9.0 | 13.5 | 18.0 | 27.0 | 36.0 | 45.0 | 54.0 |

| M20x1.5 | 1.5 | 20.5 | 20.32 | 20.56 | 21.95 | 10.0 | 15.0 | 20.0 | 30.0 | 40.0 | – | – |

| M20x2 | 2.0 | 20.5 | 20.43 | 20.73 | 22.60 | 10.0 | 15.0 | 20.0 | 30.0 | 40.0 | – | – |

| M20 | 2.5 | 20.75 | 20.54 | 20.90 | 23.25 | 10.0 | 15.0 | 20.0 | 30.0 | 40.0 | 50.0 | 60.0 |

| M22x1.5 | 1.5 | 22.5 | 22.32 | 22.56 | 23.95 | 11.0 | 16.5 | 22.0 | 33.0 | 44.0 | – | – |

| M22x2 | 2.0 | 22.5 | 22.43 | 22.73 | 24.60 | 11.0 | 16.5 | 22.0 | 33.0 | 44.0 | – | – |

| M22 | 2.5 | 22.75 | 22.54 | 22.90 | 25.25 | 11.0 | 16.5 | 22.0 | 33.0 | 44.0 | 55.0 | – |

| M24x1.5 | 1.5 | 24.5 | 24.32 | 24.56 | 25.95 | 12.0 | 18.0 | 24.0 | 36.0 | 48.0 | – | – |

| M24x2 | 2.0 | 24.5 | 24.43 | 24.73 | 26.60 | 12.0 | 18.0 | 24.0 | 36.0 | 48.0 | – | – |

| M24 | 3.0 | 24.75 | 24.65 | 25.05 | 27.90 | 12.0 | 18.0 | 24.0 | 36.0 | 48.0 | 60.0 | – |

| M26x1.5 | 1.5 | 26.5 | 26.32 | 26.56 | 27.95 | 13.0 | 19.5 | 26.0 | 39.0 | 52.0 | – | – |

| M27x1.5 | 1.5 | 27.5 | 27.32 | 27.56 | 28.95 | 13.5 | 20.3 | 27.0 | 40.5 | 54.0 | – | – |

| M27x2 | 2.0 | 27.5 | 27.43 | 27.73 | 29.60 | 13.5 | 20.3 | 27.0 | 40.5 | 54.0 | – | – |

| M27 | 3.0 | 27.75 | 27.65 | 28.05 | 30.90 | 13.5 | 20.3 | 27.0 | 40.5 | 54.0 | – | – |

| M28x1.5 | 1.5 | 28.5 | 28.32 | 28.56 | 29.95 | 14.0 | 21.0 | 28.0 | 42.0 | 56.0 | – | – |

| M30x1.5 | 1.5 | 30.5 | 30.22 | 30.56 | 31.95 | 15.0 | 22.5 | 30.0 | 45.0 | 60.0 | – | – |

| M30x2 | 2.0 | 30.5 | 30.43 | 30.73 | 32.60 | 15.0 | 22.5 | 30.0 | 45.0 | 60.0 | – | – |

| M30 | 3.5 | 31.0 | 30.76 | 31.21 | 34.55 | 15.0 | 22.5 | 30.0 | 45.0 | 60.0 | – | – |

| M33x2 | 2.0 | 33.5 | 33.43 | 33.73 | 35.60 | 16.5 | 24.8 | 33.0 | 49.5 | 66.0 | – | – |

| M33 | 3.5 | 34.0 | 33.76 | 34.21 | 37.55 | 16.5 | 24.8 | 33.0 | 49.5 | 66.0 | – | – |

| M34x1.5 | 1.5 | 34.5 | 34.32 | 34.56 | 35.95 | 17.0 | 25.5 | 34.0 | 51.0 | 68.0 | – | – |

| M36x1.5 | 1.5 | 36.5 | 36.32 | 36.56 | 37.95 | 18.0 | 27.0 | 36.0 | 54.0 | 72.0 | – | – |

| M36x2 | 2.0 | 36.5 | 36.43 | 36.73 | 38.60 | 18.0 | 27.0 | 36.0 | 54.0 | 72.0 | – | – |

| M36x3 | 3.0 | 37.0 | 36.65 | 37.05 | 39.90 | 18.0 | 27.0 | 36.0 | 54.0 | 72.0 | – | – |

| M36 | 4.0 | 37.0 | 36.87 | 37.34 | 41.20 | 18.0 | 27.0 | 36.0 | 54.0 | 72.0 | – | – |

| M39x3 | 3.0 | 40.0 | 39.65 | 40.05 | 42.90 | 19.5 | 29.3 | 39.0 | 58.5 | 78.0 | – | – |

| M39 | 4.0 | 40.0 | 39.87 | 40.34 | 44.20 | – | 29.3 | 39.0 | 58.5 | 78.0 | – | – |

| M42x3 | 3.0 | 43.0 | 42.65 | 43.05 | 45.90 | 21.0 | 31.5 | 42.0 | 63.0 | 84.0 | – | – |

| M42 | 4.5 | 43.0 | 42.98 | 43.50 | 47.85 | – | 31.5 | 42.0 | 63.0 | 84.0 | – | – |

| M45x3 | 3.0 | 46.0 | 45.65 | 46.05 | 48.90 | 22.5 | 33.8 | 45.0 | 67.5 | 90.0 | – | – |

| M45 | 4.5 | 46.0 | 45.98 | 46.50 | 50.85 | – | 33.8 | 45.0 | 67.5 | 90.0 | – | – |

*All information is strictly informative

Fasteners Threaded Insert Drilling Depth (Metric) Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Threaded Insert Drilling Depth (Metric) / Fasteners Threaded Insert Drilling Depth (Metric)Fasteners Threaded Insert Drilling Depth (Metric) Dimensions, Weight Chart & Material Specification & Tolerances

Threaded Insert Drilling Depth (Metric)

| Nominal Diameter | Pitch (mm) | Drill Bit Diameter (mm) | Drilling Diameter | Tap | Minimum Drilling Depth | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | Min Outer Diameter | 0.5d | 0.75d | 1d | 1.5d | 2d | 2.5d | 3d | |||

| M2 | 0.4 | 2.1 | 2.09 | 2.18 | 2.52 | – | – | 3.6 | 4.6 | 5.6 | 6.6 | 7.6 |

| M2.5 | 0.45 | 2.6 | 2.60 | 2.70 | 3.08 | – | – | 5.1 | 6.3 | 7.6 | 8.9 | 10.1 |

| M3 | 0.5 | 3.2 | 3.11 | 3.22 | 3.65 | – | – | 5.8 | 7.3 | 8.8 | 10.3 | 11.8 |

| M3.5 | 0.6 | 3.7 | 3.63 | 3.76 | 4.28 | – | – | 6.9 | 8.6 | 10.4 | 12.2 | 13.9 |

| M4 | 0.7 | 4.2 | 4.15 | 4.29 | 4.91 | – | – | 7.8 | 9.8 | 11.8 | 13.8 | 15.8 |

| M5 | 0.8 | 5.2 | 5.17 | 5.33 | 6.04 | – | – | 9.2 | 11.7 | 14.2 | 16.7 | 19.2 |

| M6 | 1.0 | 6.3 | 6.22 | 6.41 | 7.30 | – | – | 11.2 | 14.2 | 17.2 | 20.2 | 23.2 |

| M7 | 1.0 | 7.3 | 7.22 | 7.41 | 8.30 | – | – | 12.1 | 15.6 | 19.1 | 22.6 | 26.1 |

| M8x1 | 1.0 | 8.3 | 8.22 | 8.41 | 9.30 | – | – | 13.0 | 17.0 | 21.0 | 25.0 | 29.0 |

| M8 | 1.25 | 8.4 | 8.27 | 8.48 | 9.62 | – | – | 14.2 | 18.2 | 22.2 | 26.2 | 30.2 |

| M9 | 1.25 | 9.4 | 9.27 | 9.48 | 10.62 | – | – | 15.2 | 19.7 | 24.2 | 28.7 | 33.2 |

| M10x1 | 1.0 | 10.25 | 10.22 | 10.41 | 11.30 | – | – | 15.0 | 20.0 | 25.0 | 30.0 | 35.0 |

| M10x1.25 | 1.25 | 10.4 | 10.27 | 10.48 | 11.62 | – | – | 16.2 | 21.2 | 26.2 | 31.2 | 36.2 |

| M10 | 1.5 | 10.5 | 10.32 | 10.56 | 11.95 | – | – | 17.3 | 22.3 | 27.3 | 32.3 | 37.3 |

| M11 | 1.5 | 11.5 | 11.32 | 11.56 | 12.95 | – | – | 18.3 | 23.8 | 29.3 | 34.8 | 40.3 |

| M12x1 | 1.0 | 12.3 | 12.22 | 12.41 | 13.30 | – | – | 17.2 | 23.2 | 29.2 | 35.2 | 41.2 |

| M12x1.25 | 1.25 | 12.4 | 12.27 | 12.48 | 13.62 | – | – | 18.2 | 24.2 | 30.2 | 36.2 | 42.2 |

| M12x1.5 | 1.5 | 12.5 | 12.32 | 12.56 | 13.95 | – | – | 19.3 | 25.3 | 31.3 | 37.3 | 43.3 |

| M12 | 1.75 | 12.5 | 12.38 | 12.64 | 14.27 | – | – | 20.3 | 26.3 | 32.3 | 38.3 | 44.3 |

| M14x1.25 | 1.25 | 14.4 | 14.27 | 14.48 | 15.62 | 13.2 | 16.7 | 20.2 | 27.2 | 34.2 | 41.2 | 48.2 |

| M14x1.5 | 1.5 | 14.5 | 14.32 | 14.56 | 15.95 | – | 17.7 | 21.3 | 28.3 | 35.3 | 42.3 | 49.3 |

| M14 | 2.0 | 14.5 | 14.43 | 14.73 | 16.60 | – | – | 23.3 | 30.3 | 37.3 | 44.3 | 51.3 |

| M16x1.5 | 1.5 | 16.5 | 16.32 | 16.56 | 17.95 | – | 19.3 | 23.3 | 31.3 | 39.3 | 47.3 | – |

| M16 | 2.0 | 16.5 | 16.43 | 16.73 | 18.60 | – | – | 25.3 | 33.3 | 41.3 | 49.3 | 57.3 |

| M18x1.5 | 1.5 | 18.5 | 18.32 | 18.56 | 19.95 | 16.3 | 20.8 | 25.3 | 34.3 | 43.3 | – | – |

| M18x2 | 2.0 | 18.5 | 18.43 | 18.73 | 20.60 | 18.3 | 22.8 | 27.3 | 36.3 | 45.3 | 54.3 | 62.0 |

| M18 | 2.5 | 18.75 | 18.54 | 18.90 | 21.25 | 20.2 | 24.7 | 29.2 | 38.2 | 47.2 | 56.2 | 64.0 |

| M20x1.5 | 1.5 | 20.5 | 20.32 | 20.56 | 21.95 | 17.3 | 22.3 | 27.3 | 37.3 | 47.3 | – | – |

| M20x2 | 2.0 | 20.5 | 20.43 | 20.73 | 22.60 | 19.3 | 24.3 | 29.3 | 39.3 | 49.3 | – | – |

| M20 | 2.5 | 20.75 | 20.54 | 20.90 | 23.25 | 21.2 | 26.2 | 31.2 | 41.2 | 51.2 | 61.2 | 71.2 |

| M22x1.5 | 1.5 | 22.5 | 22.32 | 22.56 | 23.95 | 18.3 | 23.8 | 29.3 | 40.3 | 51.3 | – | – |

| M22x2 | 2.0 | 22.5 | 22.43 | 22.73 | 24.60 | 20.3 | 25.8 | 31.3 | 42.3 | 53.3 | – | – |

| M22 | 2.5 | 22.75 | 22.54 | 22.90 | 25.25 | 22.2 | 27.7 | 33.2 | 44.2 | 55.2 | 66.2 | – |

| M24x1.5 | 1.5 | 24.5 | 24.32 | 24.56 | 25.95 | 19.3 | 25.3 | 31.3 | 43.3 | 55.3 | – | – |

| M24x2 | 2.0 | 24.5 | 24.43 | 24.73 | 26.60 | 21.3 | 27.3 | 33.3 | 45.3 | 57.3 | – | – |

| M24 | 3.0 | 24.75 | 24.65 | 25.05 | 27.90 | 25.1 | 31.1 | 37.1 | 49.1 | 61.1 | 73.1 | – |

| M26x1.5 | 1.5 | 26.5 | 26.32 | 26.56 | 27.95 | 20.3 | 26.8 | 33.3 | 46.3 | 59.3 | – | – |

| M27x1.5 | 1.5 | 27.5 | 27.32 | 27.56 | 28.95 | 20.8 | 27.6 | 34.3 | 47.8 | 61.3 | – | – |

| M27x2 | 2.0 | 27.5 | 27.43 | 27.73 | 29.60 | 22.8 | 29.6 | 36.3 | 49.8 | 63.3 | – | – |

| M27 | 3.0 | 27.75 | 27.65 | 28.05 | 30.90 | 26.6 | 33.4 | 40.1 | 53.6 | 67.1 | – | – |

| M28x1.5 | 1.5 | 28.5 | 28.32 | 28.56 | 29.95 | 21.3 | 28.3 | 35.3 | 49.3 | 63.3 | – | – |

| M30x1.5 | 1.5 | 30.5 | 30.22 | 30.56 | 31.95 | 22.3 | 29.8 | 37.3 | 52.3 | 67.3 | – | – |

| M30x2 | 2.0 | 30.5 | 30.43 | 30.73 | 32.60 | 24.3 | 31.8 | 39.3 | 54.3 | 69.3 | – | – |

| M30 | 3.5 | 31.0 | 30.76 | 31.21 | 34.55 | 30.3 | 37.8 | 45.3 | 60.3 | 75.3 | – | – |

| M33x2 | 2.0 | 33.5 | 33.43 | 33.73 | 35.60 | 25.8 | 34.1 | 42.3 | 58.8 | 75.3 | – | – |

| M33 | 3.5 | 34.0 | 33.76 | 34.21 | 37.55 | 31.7 | 40.0 | 48.2 | 64.7 | 81.2 | – | – |

| M34x1.5 | 1.5 | 34.5 | 34.32 | 34.56 | 35.95 | 24.3 | 32.8 | 41.3 | 58.3 | 75.3 | – | – |

| M36x1.5 | 1.5 | 36.5 | 36.32 | 36.56 | 37.95 | 25.3 | 34.3 | 43.3 | 61.3 | 49.3 | – | – |

| M36x2 | 2.0 | 36.5 | 36.43 | 36.73 | 38.60 | 27.3 | 36.6 | 45.3 | 63.3 | 81.3 | – | – |

| M36x3 | 3.0 | 37.0 | 36.65 | 37.05 | 39.90 | 31.1 | 40.1 | 49.1 | 67.1 | 85.1 | – | – |

| M36 | 4.0 | 37.0 | 36.87 | 37.34 | 41.20 | 34.8 | 13.8 | 52.8 | 70.8 | 88.8 | – | – |

| M39x3 | 3.0 | 40.0 | 39.65 | 40.05 | 42.90 | 32.6 | 42.4 | 52.1 | 71.6 | 91.1 | – | – |

| M39 | 4.0 | 40.0 | 39.87 | 40.34 | 44.20 | – | 46.1 | 55.8 | 75.3 | 94.8 | – | – |

| M42x3 | 3.0 | 43.0 | 42.65 | 43.05 | 45.90 | 34.1 | 44.6 | 55.1 | 76.1 | 97.1 | – | – |

| M42 | 4.5 | 43.0 | 42.98 | 43.50 | 47.85 | – | 46.0 | 57.5 | 78.5 | 9935 | – | – |

| M45x3 | 3.0 | 46.0 | 45.65 | 46.05 | 48.90 | 35.6 | 46.9 | 58.1 | 80.6 | 103.1 | – | – |

| M45 | 4.5 | 46.0 | 45.98 | 46.50 | 50.85 | – | 49.3 | 60.5 | 83.0 | 105.5 | – | – |

*All information is strictly informative

Fasteners Mechanical Properties Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Mechanical Properties / Fasteners Mechanical PropertiesFasteners Mechanical Properties Dimensions, Weight Chart & Material Specification & Tolerances

Mechanical Properties

| Property | 3.6 | 4.6 | 4.8 | 5.6 | 5.8 | 6.8 | 8.8 | 10.9 | 12.9 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| <= 16mm | > 16mm | ||||||||||

| Tensile Strength | nominal value | 300 | 400 | 400 | 500 | 500 | 600 | 800 | 800 | 1000 | 1200 |

| minimum | 330 | 400 | 420 | 500 | 520 | 600 | 800 | 830 | 1040 | 1220 | |

| Vickers Hardness HV=F 98N | minimum | 95 | 120 | 130 | 155 | 160 | 190 | 230 | 255 | 310 | 372 |

| maximum | 220 | 220 | 220 | 220 | 220 | 250 | 300 | 336 | 382 | 434 | |

| Brinell Hardness HB F=30D2 | minimum | 90 | 114 | 124 | 147 | 152 | 181 | 219 | 242 | 295 | 353 |

| maximum | 209 | 238 | 285 | 319 | 363 | 412 | |||||

| Rockwell Hardness HR | minimum HRB | 52 | 67 | 71 | 79 | 82 | 89 | ||||

| minimum HRC | 20 | 23 | 31 | 38 | |||||||

| maximum HRB | 95 | 95 | 95 | 95 | 95 | ||||||

| maximum HRC | 30 | 34 | 39 | 44 | |||||||

| Surface Hardness HV 0.3 | maximum | 320 | 356 | 402 | 454 | ||||||

| Yield Stress Rel in MPa(N/mm2) | nominal value | 180 | 240 | 320 | 300 | 400 | 480 | ||||

| minimum | 190 | 240 | 340 | 300 | 420 | 480 | |||||

| 0.2% elongation limit Rp0.2 in Mpa (N/mm2) | nominal value | 640 | 640 | 900 | 1080 | ||||||

| minimum | 640 | 660 | 940 | 1100 | |||||||

| Test stress Sp | Sp/ReL or Rp0.2 | 0.94 | 0.94 | 0.91 | 0.94 | 0.91 | 0.91 | 0.91 | 0.91 | 0.88 | 0.88 |

| MPA (N/mm2) | 180 | 225 | 310 | 280 | 380 | 440 | 580 | 600 | 830 | 970 | |

| Elongation after fracture A5 in % | minimum | 25 | 22 | 14 | 20 | 10 | 8 | 12 | 12 | 9 | 8 |

| Minimum notch impact energy in Joules | 25 | 30 | 30 | 20 | 15 | ||||||

| Head Impact Toughness | No Fracture | ||||||||||

| Maximum Height of the Thread Zone Not Decarburized E | 1/2H1 | 1/2H1 | 2/3H1 | 3/4H1 | |||||||

| Maximum Depth of Decarburization Gmm | .015 | .015 | .015 | .015 | |||||||

Mechanical Properties for Socket Products

DIN 912 Socket Cap Screws

| Property Class | 12.9 |

|---|---|

| Hardness (HRC) | 39-44 |

| Tensile Strength (Mpa) | 1,220 min. |

| Yield Strength at 0.2% Offset (Mpa) | 1,100 min. |

| Elongation (%) | 8 min. |

| Diameter d | d <= 1/2 | d > 1/2 |

|---|---|---|

| Hardness (HRC) | 39-44 | 37-44 |

| Tensile Strength (psi) | 145,000 min. | 135,000 min. |

| Property Class | 10.9 |

|---|---|

| Hardness (HRC) | 32-39 |

| Tensile Strength (Mpa) | 832 min. |

ASME B18.3 Low Head Socket Caps

| Diameter d | d <= 1/2 | d > 1/2 |

|---|---|---|

| Hardness (HRC) | 39-45 | 37-45 |

| Tensile Strength (psi) | 180,000 min. | 170,000 min. |

| Yield Strength at 0.2% Offset (psi) | 153,000 min. | 153,000 min. |

| Elongation (%) | 10 min. | 10 min. |

DIN 7991 Flat Head Countersunk Socket Cap Screws

| Property Class | 10.9 |

|---|---|

| Hardness (HRC) | 32-39 |

| Tensile Strength (Mpa) | 835 min. |

ASME B18.3 Flat Head Countersunk Socket Cap Screws

| Diameter d | d <= 1/2 | d > 1/2 |

|---|---|---|

| Hardness (HRC) | 39-44 | 37-44 |

| Tensile Strength (psi) | 145,000 min. | 135,000 min. |

ISO 7380 Button Head Socket Cap Screws

| Property Class | 10.9 |

|---|---|

| Hardness (HRC) | 32-39 |

| Tensile Strength (Mpa) | 835 min. |

ASME B18.3 Button Head Socket Cap Screws

| Diameter d | d <= 1/2 | d > 1/2 |

|---|---|---|

| Hardness (HRC) | 39-44 | 37-44 |

| Tensile Strength (psi) | 145,000 min. | 135,000 min. |

ISO 7379 Socket Shoulder Screws

| Property Class | 12.9 |

|---|---|

| Hardness (HRC) | 39-44 |

| Tensile Strength (Mpa) | 1,100 min. |

ASME B18.3 Socket Shoulder Screws

| Hardness (HRC) | 39-43 |

| Tensile Strength (psi) | 140,000 min. |

| Property Class | 45H |

|---|---|

| Hardness (HRC) | 45-53 |

| Property Class | 45H |

|---|---|

| Hardness (HRC) | 45-53 |

Mechanical Properties for Hex Products

ISO 4014 / 4017 Hex Head Bolts

| Property Class | 10.9 | 12.9 |

|---|---|---|

| Hardness (HRC) | 32-39 | 39-44 |

| Tensile Strength (Mpa) | 1,040 min. | 1,220 min. |

| Yield Strength at 0.2% Offset (Mpa) | 940 min. | 1,100 min. |

| Elongation (%) | 9 min. | 8 min. |

ASME B18.2.1 Hexagon Head Cap Screws

| Property Class | SAE J429-Grade 8 |

|---|---|

| Hardness (HRC) | 33-39 |

| Surface Hardness (30N) | 58.6 max. |

| Tensile Strength (psi) | 150,000 min. |

| Yield Strength at 0.2% Offset (psi) | 130,000 min. |

| Elongation (%) | 12 min. |

| Property Class | 10.9 | 12.9 |

|---|---|---|

| Hardness (HRC) | 32-39 | 39-44 |

| Tensile Strength (Mpa) | 1,040 min. | 1,220 min. |

| Yield Strength at 0.2% Offset (Mpa) | 940 min. | 1,100 min. |

| Elongation (%) | 9 min. | 8 min. |

| Property Class | SAE J429-Grade 8 |

|---|---|

| Hardness (HRC) | 33-39 |

| Surface Hardness (30N) | 58.6 max. |

| Tensile Strength (psi) | 150,000 min. |

| Yield Strength at 0.2% Offset (psi) | 130,000 min. |

| Elongation (%) | 12 min. |

*All information is strictly informative

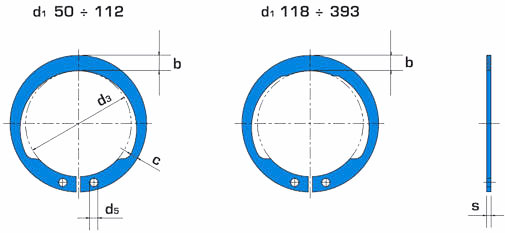

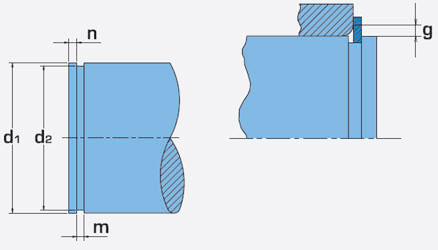

Fasteners External Inverted Ring Specifications Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners External Inverted Ring Specifications / Fasteners External Inverted Ring Specifications

Fasteners External Inverted Ring Specifications Dimensions, Weight Chart & Material Specification & Tolerances

External Inverted Ring Specifications

All measurements in millimeters (mm)

| Ring n° | d1 | s | d3 | b | c | d5 | d2 | m | n | FN | FR | g | FRg | nabl | lbs | Tool | Ring n° | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 0.500 | 0.035 | +0.002 | 0.461 | +0.005 | 0.080 | +0.004 | 0.041 | +0.004 | 0.042 | +0.010 | 0.468 | +0.002 | 0.039 | +0.003 | 0.048 | 280 | 1117 | 0.032 | 680 | 40000 | 1.000 | A0 | A01 | 50 |

| -0.002 | -0.010 | -0.004 | -0.004 | -0.002 | -0.002 | -0.000 | |||||||||||||||||||

| 56 | 0.562 | 0.035 | +0.002 | 0.521 | +0.005 | 0.088 | +0.004 | 0.043 | +0.004 | 0.042 | +0.010 | 0.530 | +0.002 | 0.039 | +0.003 | 0.048 | 320 | 1269 | 0.036 | 680 | 35000 | 1.400 | A0 | A01 | 56 |

| -0.002 | -0.010 | -0.004 | -0.004 | -0.002 | -0.002 | -0.000 | |||||||||||||||||||

| 59 | 0.594 | 0.035 | +0.002 | 0.550 | +0.005 | 0.092 | +0.004 | 0.046 | +0.004 | 0.042 | +0.010 | 0.559 | +0.003 | 0.039 | +0.003 | 0.052 | 370 | 1320 | 0.037 | 680 | 32000 | 1.600 | A0 | A01 | 59 |

| -0.002 | -0.010 | -0.004 | -0.004 | -0.002 | -0.003 | -0.000 | |||||||||||||||||||

| 62 | 0.625 | 0.035 | +0.002 | 0.579 | +0.005 | 0.096 | +0.004 | 0.048 | +0.004 | 0.042 | +0.010 | 0.588 | +0.003 | 0.039 | +0.003 | 0.055 | 400 | 1421 | 0.039 | 680 | 30000 | 1.600 | A0 | A01 | 62 |

| -0.002 | -0.010 | -0.004 | -0.004 | -0.002 | -0.003 | -0.000 | |||||||||||||||||||

| 68 | 0.688 | 0.042 | +0.002 | 0.635 | +0.005 | 0.104 | +0.005 | 0.052 | +0.005 | 0.042 | +0.010 | 0.646 | +0.003 | 0.046 | +0.003 | 0.063 | 500 | 2335 | 0.042 | 1000 | 28000 | 2.500 | A0 | A01 | 68 |

| -0.002 | -0.010 | -0.005 | -0.005 | -0.002 | -0.003 | -0.000 | |||||||||||||||||||

| 75 | 0.750 | 0.042 | +0.002 | 0.693 | +0.005 | 0.112 | +0.005 | 0.056 | +0.005 | 0.042 | +0.010 | 0.704 | +0.003 | 0.046 | +0.003 | 0.069 | 600 | 2538 | 0.045 | 1000 | 26500 | 2.800 | A0 | A01 | 75 |

| -0.002 | -0.010 | -0.005 | -0.005 | -0.002 | -0.003 | -0.000 | |||||||||||||||||||

| 78 | 0.781 | 0.042 | +0.002 | 0.722 | +0.005 | 0.116 | +0.005 | 0.057 | +0.005 | 0.042 | +0.010 | 0.733 | +0.003 | 0.046 | +0.003 | 0.072 | 650 | 2639 | 0.046 | 1000 | 25500 | 3.100 | A0 | A01 | 78 |

| -0.002 | -0.010 | -0.005 | -0.005 | -0.002 | -0.003 | -0.000 | |||||||||||||||||||

| 81 | 0.812 | 0.042 | +0.002 | 0.751 | +0.005 | 0.120 | +0.005 | 0.060 | +0.005 | 0.050 | +0.010 | 0.762 | +0.003 | 0.046 | +0.003 | 0.075 | 700 | 2690 | 0.048 | 1000 | 24500 | 3.300 | A0 | A01 | 81 |

| -0.002 | -0.010 | -0.005 | -0.005 | -0.002 | -0.003 | -0.000 | |||||||||||||||||||

LINKS HERE

*All information is strictly informative

Platings and Finishes Dimensions, Weight Chart & Material Specification & Tolerances / Platings and Finishes / Platings and Finishes / Platings and Finishes Dimensions, Weight Chart & Material Specification & Tolerances

Platings and Finishes

| Finish | Color | Anti-Corrosion Properties | Used With | Characteristics And Uses |

|---|---|---|---|---|

| Black Oxide | Black | Good-Interior Only | Most metals | Decorative finish. Used on interior applications. |

| Black Zinc | Black | Excellent | All metals | Rich and lustrous. With or without lacquering. |

| Cadmium | Bright Silver-gray Dull or burnished | Very Good | Most metals | Non-porous metallic plating. Rich appearance, good rust resistance, low cost, good electrical conductivity. Bright silver-gray dull gray or black electroplated finish. |

| Chromium (Chrome) | Bright Blue-white | Excellent | All metals | Used wherever a beautiful finish is desired. Bright blue-white lustrous appearance. Electroplated. |

| Dichromate Dip | Rainbow | Excellent | All metals | A yellow, brown, green or iridescent colored catalog. This dipping process gently increases rust resistance. Add to Zinc or Cadmium plating. |

| E-Coat | Black | Excellent-168 Hour Salt Spray | All metals | Added protection containing corrosion inhibitors. Excellent for exterior applications. |

| Iridite | Green, Blue, Olive Drab, Red, Bronze, Black | Excellent | All metals | A colouring dip which also adds rust resistance. Usually applied on Zinc or Cadmium. |

| JS-500 | Chrome-like luster | Excellent-500 Hour Salt Spray | All metals | Outstanding corrosion resistant finish that provides economical corrosion protection without adversely affecting dimensions. |

| Nickel | Silver | Very good | All metals | A hard stable, dull white or bright burnished finish. Used for appliances and hardware. |

| Parkerized | Black | Excellent | Ferrous metals | Added protection when oiled with a non-drying petroleum oil containing corrosion inhibitors. Good lubricity. |

| Phosphating | Dull, gray, black, or blue | Excellent | Ferrous metals | A chemical process of rust-proofing steel. |

| Passivating | – | Excellent | Stainless steels | For stainless steels. A nitric acid dip to remove foreign material and brighten finish. |

| Zinc Electrogalvanized | Gray | Very good | All metals | A commonly used finish with good rust resistance, appearance and low cost. |

*All information is strictly informative

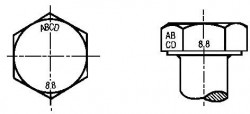

Grade Markings for Metric Fasteners Dimensions, Weight Chart & Material Specification & Tolerances / Grade Markings for Metric Fasteners / Grade Markings for Metric Fasteners

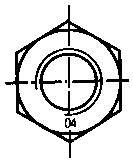

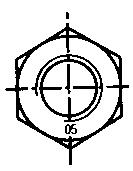

Grade Markings for Metric Fasteners

Examples of markings on socket head cap screws.

Marking Of Nuts

(According to ISO 898 – Part II)

| Property Class | 04 | 05 | 4 | 5 | 6 | 8 | 9 | 10 | 12 |

|---|---|---|---|---|---|---|---|---|---|

| Either designation Symbol | 04 | 05 | 4 | 5 | 6 | 8 | 9 | 10 | 12 |

| Code (Clock Symbol) Symbol |  |  |  |  |  |  |  |  |  |

| Identification with the manufacturer’s mark and property class is mandatory for hexagon nuts with thread diameter d ≥ 5 mm. The hexagon nuts must be marked with an indentation on the bearing surface or on the side or by embossing on the chamfer. Embossed markings must not protrude beyond the bearing surface of the nut. |

*All information is strictly informative

Fasteners Finish K Factors Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Finish K Factors / Fasteners Finish K Factors

| Fastener Finish K Factors | |||||

| As received steel | 0.18 | GEOBLACK® 147 | 0.15 | Magni 575 | 0.13 |

| Black Oxide | 0.20 | GEOBLACK® ML | 0.16 | Magni 590 | 0.11 |

| Cadmium plated nuts and bolts | 0.19 | GEOMET® 500 A | 0.17 | Magni 591 | 0.11 |

| Copper based antiseize | 0.13 | GEOMET® 500 B | 0.17 | Magni 594 | 0.12 |

| DACROBLACK® 107 | 0.14 | GEOMET® 720 L | 0.15 | Never-Seize Paste | 0.17 |

| DACROBLACK® 127 | 0.15 | GEOMET® 720 ML | 0.17 | Phosphate & Oil | 0.18 |

| DACROMET® 500 A | 0.19 | GEOMET® L | 0.15 | Plain | 0.20 |

| DACROMET® 500 B | 0.19 | GEOMET® MlL | 0.17 | Rusty (exposed outdoors 2 wks) | 0.39 |

| DACROMET® L | 0.15 | GEOMET® P | 0.20 | SermaGard (Aluminum particles in a ceramic binder) basecoat + wax | 0.23 |

| DACROMET® ML | 0.17 | GEOMET® XL | 0.09 | Xylan 5230 (PTFE) | 0.12 |

| DACROMET® P | 0.20 | Graphite coatings | 0.19 | Zinc & Black (cr6) | 0.22 |

| DACROMET® XL | 0.09 | Hot dip galvanized - clean and dry | 0.23 | Zinc & Clear (cr6) | 0.22 |

| Delta-Protekt KL 100 base coat with Delta VH 301 topcoat | 0.17 | Machine Oil | 0.21 | Zinc & Clear (cr6) & Waxed Locknut | 0.18 |

| Delta-Protekt KL 100 base coat with Delta VH 302 topcoat | 0.19 | Magni 510 | 0.15 | Zinc & Olive (cr6) | 0.22 |

| Delta-Protekt KL 100 base coat with Delta-Seal | 0.23 | Magni 5111 | 0.15 | Zinc & Yellow (cr6) | 0.22 |

| Delta-Protekt KL 100 base coat with Delta-Seal GZ | 0.18 | Magni 515 | 0.15 | Zinc (mechanical) & Clear (cr6) | 0.35 |

| GEOBLACK® 117 | 0.20 | Magni 560 | 0.13 | Zinc-Cobalt electroplated finish | 0.30 |

| GEOBLACK® 137 | 0.17 | Magni 565 | 0.13 | Zinc-Nickel electroplated finish | 0.30 |

| Note: Values determined using DIN 946. |

Fasteners Steels For Screws, Bolts and Studs Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Steels For Screws, Bolts and Studs / Fasteners Steels For Screws, Bolts and Studs

Steels generally used for metric screws, bolts and studs

| Property Class | Size | Materials per DIN 1) | Materials per ANSI 1) |

|---|---|---|---|

| 3.6 4.6 | to M39 | QSt 36-2 USt 38-2 UQSt 36-2 UQSt 38-2 | 1006 1010 |

| 4.8 | to M16 | QSt 36-2 QSt 38-2 | 1006 1010 |

| 5.6 | to M39 | Cq 22 | 1022 |

| 5.8 | to M39 | Cq 22 Cq 35 | 1022 1035 |

| 8.8 | to M12 | 22B2 28B2 Cq 35 | 10B22 10B28 1035 (1038) |

| to M22 | 35B2 Cq 35 Cq 45 46 Cr 1 | 10B35 1035 (1038) 1045 | |

| over M24 to M39 | 34 Cr 4 37 Cr 4 46 Cr2 | 5132 5135 | |

| 10.9 | to M6 | 35B2 Cq 35 | 10B35 1035 |

| over M6 to M18 | 34 Cr 4 41 Cr 4 | 5132 5140 | |

| to M39 | 41 Cr 4 34 CrMo 4 42 CrMo 4 | 5135 4137 4140 | |

| 12.9 | to M18 | 34 CrMo4 37 Cr 4 41 Cr 4 | 4137 5135 5140 |

| to M24 | 42CrMo 4 | 4140 | |

| to M39 | 34 CrNiMo 6 | 4340 |

| 1) The above listed materials are generally used. It is however up to the manufacturer’s discretion to use any other material providing the final product meets the specified chemical composition and mechanical property. |

*All information is strictly informative

Fasteners Standard / Metric Conversion Tables Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Standard / Metric Conversion Tables / Fasteners Standard / Metric Conversion Tables

Standard / Metric Conversion Tables

To convert inches to mm multiply inches by 25.4

To convert mm to inches multiply mm by .039370

LENGTH CONVERSION

| U.S. TO METRIC | METRIC TO U.S. | ||

|---|---|---|---|

| 1 inch | 25.400 millimeters | 1 millimeter | : .03937 inches |

| 1 inch | 2.540 centimeters | 1 centimeter | : .39370 inches |

| 1 foot | 30.480 centimeters | 1 meter | : 3.2808 feet |

| 1 yard | 0.9144 meters | 1 meter | : 1.0936 yards |

| 1 mile | 1.6093 kilometers | 1 kilometer | : .62137 miles |

MASS (WEIGHT)

| Lb. | kg | kg | Lb. |

|---|---|---|---|

| 1 | .45 | 1 | 2.20 |

| 2 | .91 | 2 | 4.41 |

| 3 | 1.36 | 3 | 6.61 |

| 4 | 1.81 | 4 | 8.82 |

| 5 | 2.27 | 5 | 11.02 |

Properties at Elevated Temperatures

Properties at Elevated Temperatures

DIN ISO 898 Standard Part 1

| Property Class | +20°C | +100°C | +200°C | +250°C | +300°C |

|---|---|---|---|---|---|

| –Lower yield stress, Rel or proof stress Rp0.2 N/mm2 — | |||||

| 5.6 | 300 | 270 | 230 | 215 | 195 |

| 8.8 | 640 | 590 | 540 | 510 | 480 |

| 10.9 | 940 | 875 | 790 | 745 | 705 |

| 12.9 | 1100 | 1020 | 925 | 875 | 825 |

*All information is strictly informative

Weights for DIN 472 Retaining Ring, DIN 472 Retaining Ring Dimensions & External Circlip DIN 471 Metric Material Specification & Tolerances / Weights For DIN 472 Retaining Ring / Weights For DIN 472 Retaining Ring / DIN 472 Retaining Ring Manufacturer & Suppliers Mumbai, India

Weights for DIN 472

Weight in kgs. per 1,000 pcs. unless otherwise specified. All weights are approximations.

| Diameter | Weight |

|---|---|

| 8 | 0.14 |

| 9 | 0.15 |

| 10 | 0.18 |

| 11 | 0.31 |

| 12 | 0.37 |

| 13 | 0.42 |

| 14 | 0.52 |

| 15 | 0.56 |

| 16 | 0.6 |

| 17 | 0.65 |

| 18 | 0.74 |

| 19 | 0.83 |

| 20 | 0.9 |

| 21 | 1 |

| 22 | 1.1 |

| 24 | 1.42 |

| 25 | 1.5 |

| 26 | 1.6 |

| 28 | 1.8 |

| 30 | 2.06 |

| 31 | 2.1 |

| 32 | 2.21 |

| 34 | 3.2 |

| 35 | 3.54 |

| 36 | 3.7 |

| 37 | 3.74 |

| 38 | 3.9 |

| 40 | 4.7 |

| 42 | 5.4 |

| 45 | 6 |

| 47 | 6.1 |

| 48 | 6.7 |

| 50 | 7.3 |

| 52 | 8.2 |

| 55 | 8.3 |

| 56 | 8.7 |

| 58 | 10.5 |

| 60 | 11.1 |

| 62 | 11.2 |

| 63 | 11.7 |

| 65 | 14.3 |

| 68 | 16 |

| 70 | 16.5 |

| 72 | 18.1 |

| 75 | 18.8 |

| 78 | 20.4 |

| 80 | 22 |

| 82 | 24 |

| 85 | 25.3 |

| 88 | 28 |

| 90 | 31 |

| 92 | 32 |

| 95 | 35 |

| 98 | 37 |

| 100 | 38 |

| 102 | 55 |

| 105 | 56 |

| 108 | 60 |

| 110 | 64.5 |

| 112 | 72 |

| 115 | 74.5 |

| 120 | 77 |

| 125 | 79 |

| 130 | 82 |

| 135 | 84 |

| 140 | 87.5 |

| 145 | 93 |

| 150 | 105 |

| 155 | 107 |

| 160 | 110 |

| 165 | 125 |

| 170 | 140 |

| 175 | 150 |

| 180 | 165 |

| 185 | 170 |

| 190 | 175 |

| 195 | 183 |

| 200 | 195 |

| 210 | 270 |

| 220 | 315 |

| 230 | 330 |

| 240 | 345 |

| 250 | 360 |

| 260 | 375 |

| 270 | 388 |

| 280 | 400 |

| 290 | 415 |

| 300 | 435 |

*All information is strictly informative

Fasteners Screw Thread Conversions Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Screw Thread Conversions / Fasteners Screw Thread Conversions

MAJOR DIAMETER (Converted to INCH Decimals)

| NOMINAL DIAMETER (mm) | MAJOR DIAMETER | |

|---|---|---|

| mm | INCH | |

| M 1 | 1 | .0393 |

| M 1.1 | 1.1 | .0433 |

| M 1.2 | 1.2 | .0472 |

| M 1.4 | 1.4 | .0551 |

| M 1.6 | 1.6 | .0629 |

| M 1.8 | 1.8 | .0708 |

| M 2 | 2 | .0787 |

| M 2.2 | 2.2 | .0866 |

| M 2.3 | 2.3 | .0905 |

| M 2.5 | 2.5 | .0984 |

| M 2.6 | 2.6 | .1023 |

| M 3 | 3 | .1181 |

| M 3.5 | 3.5 | .1378 |

| M 4 | 4 | .1574 |

| M 4.5 | 4.5 | .1771 |

| M 5 | 5 | .1968 |

| M 6 | 6 | .2362 |

| M 7 | 7 | .2755 |

| M 8 | 8 | .3149 |

| M 10 | 10 | .3937 |

| M 12 | 12 | .4724 |

| M 14 | 14 | .5511 |

| M 16 | 16 | .6299 |

| M 18 | 18 | .7086 |

| M 20 | 20 | .7874 |

| M 22 | 22 | .8661 |

| M 24 | 24 | .9448 |

| M 27 | 27 | 1.0629 |

| M 30 | 30 | 1.181 |

| M 33 | 33 | 1.299 |

| M 36 | 36 | 1.417 |

| M 39 | 39 | 1.535 |

| M 42 | 42 | 1.654 |

| M 45 | 45 | 1.772 |

| M 48 | 48 | 1.890 |

| M 52 | 52 | 2.047 |

| M 56 | 56 | 2.205 |

| M 60 | 60 | 2.362 |

| M 64 | 64 | 2.520 |

| M 68 | 68 | 2.677 |

| M 72 | 72 | 2.835 |

| M 76 | 76 | 2.992 |

| M 80 | 80 | 3.150 |

| M 85 | 85 | 3.346 |

| M 90 | 90 | 3.543 |

| M 95 | 95 | 3.740 |

| M 100 | 100 | 3.937 |

| M 105 | 105 | 4.134 |

| M 110 | 110 | 4.331 |

| M 115 | 115 | 4.538 |

| M 120 | 120 | 4.724 |

| M 125 | 125 | 4.921 |

| M 130 | 130 | 5.118 |

| M 135 | 135 | 5.315 |

| M 140 | 140 | 5.512 |

| M 145 | 145 | 5.709 |

| M 150 | 150 | 5.906 |

THREAD PITCH (Converted to Number of Threads per Inch)

| PITCH (mm) | Approx. Threads per Inch |

|---|---|

| 0.08 | 317.5 |

| 0.09 | 282.25 |

| 0.1 | 254 |

| 0.125 | 203.25 |

| 0.15 | 169.25 |

| 0.175 | 145.25 |

| 0.2 | 127 |

| 0.225 | 113 |

| 0.25 | 101.5 |

| 0.3 | 84.75 |

| 0.35 | 72.5 |

| 0.4 | 63.5 |

| 0.45 | 56.5 |

| 0.5 | 50.75 |

| 0.6 | 42.25 |

| 0.7 | 36.25 |

| 0.75 | 33.75 |

| 0.8 | 31.75 |

| 0.9 | 25.25 |

| 1 | 25.5 |

| 1.25 | 20.25 |

| 1.5 | 17 |

| 1.75 | 14.25 |

| 2 | 12.75 |

| 2.5 | 10.25 |

| 3 | 8.5 |

| 3.5 | 7.25 |

| 4 | 6.25 |

| 5 | 5 |

| 5.5 | 4.5 |

| 6 | 4.25 |

*All information is strictly informative

Weights for DIN 1652 Cold Rolled Bar, DIN 1652 Cold Rolled Bar Dimensions & DIN 1652 Rod Material Specification & Tolerances / Weights For DIN 1652 Cold Rolled Bar / Weights For DIN 1652 Cold Rolled Bar / DIN 1652 Cold Rolled Bar Manufacturer & Suppliers Mumbai, India

Weights for DIN 1652

Weight in kgs. per 1,000 pcs. unless otherwise specified. All weights are approximations.

| Diameter | Weight kg. per/m |

|---|---|

| M1 | 0.0062 |

| M2 | 0.0247 |

| M3 | 0.0555 |

| M4 | 0.0987 |

| M5 | 0.1540 |

| M6 | 0.2220 |

| M7 | 0.3020 |

| M8 | 0.3950 |

| M9 | 0.4990 |

| M10 | 0.6170 |

| M11 | 0.7460 |

| M12 | 0.8880 |

| M13 | 1.04 |

| M14 | 1.21 |

| M15 | 1.36 |

| M16 | 1.58 |

| M17 | 1.78 |

| M18 | 2.00 |

| M19 | 2.23 |

| M20 | 2.47 |

| M21 | 2.72 |

| M22 | 2.98 |

| M23 | 3.26 |

| M24 | 3.55 |

| M25 | 3.85 |

| M26 | 4.17 |

| M27 | 4.50 |

| M28 | 4.83 |

| M29 | 5.19 |

| M30 | 5.55 |

| M32 | 6.31 |

| M33 | 6.71 |

| M34 | 7.13 |

| M35 | 7.55 |

| M36 | 7.99 |

| M38 | 8.90 |

| M40 | 9.87 |

| M41 | 10.40 |

| M42 | 10.90 |

| M43 | 11.40 |

| M44 | 11.90 |

| M45 | 12.50 |

| M46 | 13.00 |

| M48 | 14.20 |

| M50 | 15.40 |

| M55 | 18.70 |

| M60 | 22.20 |

| M65 | 26.00 |

| M70 | 30.20 |

| M75 | 34.70 |

| M80 | 39.50 |

| M85 | 44.50 |

| M90 | 49.50 |

| M95 | 55.60 |

| M100 | 61.70 |

*All information is strictly informative

Fasteners Threaded Insert Nominal Length (UNC) Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Threaded Insert Nominal Length (UNC) / Fasteners Threaded Insert Nominal Length (UNC)

Threaded Insert Nominal Length (UNC)

| Nominal Diameter | Pitch (mm) | Drill Bit Diameter (mm) | Drilling Diameter | Tap | Nominal Length | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | Min Outer Diameter | 1d | 1.5d | 2d | 2.5d | 3d | |||

| 2-56 | 0.453 | 2.4 | 2.30 | 2.50 | 2.77 | 2.18 | 3.28 | 4.37 | 5.46 | 6.55 |

| 3-48 | 0.529 | 2.7 | 2.65 | 2.80 | 3.20 | 2.51 | 3.76 | 5.03 | 6.30 | 7.54 |

| 4-40 | 0.635 | 3.1 | 3.00 | 3.15 | 3.67 | 2.84 | 4.27 | 5.69 | 7.11 | 8.53 |

| 5-40 | 0.635 | 3.4 | 3.33 | 3.50 | 4.00 | 3.17 | 4.75 | 6.35 | 7.92 | 9.52 |

| 6-32 | 0.794 | 3.8 | 3.68 | 3.89 | 4.54 | 3.50 | 5.26 | 7.01 | 8.76 | 10.51 |

| 8-32 | 0.794 | 4.4 | 4.34 | 4.52 | 5.20 | 4.16 | 6.25 | 8.33 | 10.41 | 12.50 |

| 10-24 | 1.058 | 5.2 | 5.06 | 5.28 | 6.20 | 4.82 | 7.24 | 9.65 | 12.06 | 14.48 |

| 12-24 | 1.058 | 5.8 | 5.72 | 5.92 | 6.86 | 5.48 | 8.23 | 10.97 | 13.71 | 16.46 |

| 1/4-20 | 1.270 | 6.7 | 6.62 | 6.86 | 8.00 | 6.35 | 9.52 | 12.70 | 15.87 | 19.05 |

| 5/16-18 | 1.411 | 8.4 | 8.24 | 8.49 | 9.77 | 7.92 | 11.91 | 15.87 | 19.83 | 23.80 |

| 3/8-16 | 1.588 | 10.0 | 9.89 | 10.12 | 11.59 | 9.52 | 14.27 | 19.05 | 23.80 | 28.57 |

| 7/16-14 | 1.814 | 11.6 | 11.51 | 11.78 | 13.47 | 11.11 | 16.66 | 22.22 | 27.78 | 33.32 |

| 1/2-13 | 1.954 | 13.2 | 13.12 | 13.40 | 15.24 | 12.70 | 19.05 | 25.40 | 31.75 | 38.10 |

| 9/16-12 | 2.117 | 14.9 | 14.75 | 15.03 | 17.04 | 14.27 | 21.43 | 28.57 | 35.71 | 42.85 |

| 5/8-11 | 2.309 | 16.5 | 16.38 | 16.68 | 18.88 | 15.87 | 23.80 | 31.75 | 39.67 | 47.62 |

| 3/4-10 | 2.540 | 19.8 | 19.60 | 19.91 | 22.35 | 19.05 | 28.57 | 38.10 | 47.62 | 57.15 |

| 7/8-9 | 2.822 | 23.0 | 22.84 | 23.18 | 25.89 | 22.22 | 33.32 | 44.45 | 55.55 | 66.67 |

| 1″-8 | 3.175 | 26.4 | 26.09 | 26.47 | 29.53 | 25.40 | 38.10 | 50.80 | 63.50 | 76.20 |

| 1″ 1/8-7 | 3.629 | 29.5 | 29.36 | 29.74 | 33.29 | 28.57 | 42.85 | 57.15 | 71.42 | 85.72 |

| 1″ 1/4-7 | 3.629 | 32.8 | 32.54 | 32.92 | 36.46 | 31.75 | 47.62 | 63.50 | 79.37 | 95.25 |

| 1″ 3/8-6 | 4.234 | 36.2 | 35.84 | 36.35 | 40.42 | 34.92 | 52.37 | 69.85 | 87.30 | 104.77 |

| 1″ 1/2-6 | 4.234 | 39.5 | 39.02 | 39.53 | 43.62 | 38.10 | 57.15 | 76.20 | 95.25 | 114.30 |

*All information is strictly informative

Fasteners Threaded Insert Fitted (UNC) Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Threaded Insert Fitted (UNC) / Fasteners Threaded Insert Fitted (UNC)

Threaded Insert Fitted (UNC)

| Nominal Diameter | Pitch (mm) | Drill Bit Diameter (mm) | Drilling Diameter | Tap | Insert Fitted | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | Min Outer Diameter | 1d | 1.5d | 2d | 2.5d | 3d | |||

| 2-56 | 0.453 | 2.4 | 2.30 | 2.50 | 2.77 | 1.7 | 2.8 | 3.9 | 5.0 | 6.1 |

| 3-48 | 0.529 | 2.7 | 2.65 | 2.80 | 3.20 | 2.0 | 3.2 | 4.5 | 5.8 | 7.0 |

| 4-40 | 0.635 | 3.1 | 3.00 | 3.15 | 3.67 | 2.2 | 3.6 | 5.1 | 6.5 | 7.9 |

| 5-40 | 0.635 | 3.4 | 3.33 | 3.50 | 4.00 | 2.5 | 4.1 | 5.7 | 7.3 | 8.9 |

| 6-32 | 0.794 | 3.8 | 3.68 | 3.89 | 4.54 | 2.7 | 4.5 | 6.2 | 8.0 | 9.7 |

| 8-32 | 0.794 | 4.4 | 4.34 | 4.52 | 5.20 | 3.4 | 5.5 | 7.5 | 9.6 | 11.7 |

| 10-24 | 1.058 | 5.2 | 5.06 | 5.28 | 6.20 | 3.8 | 6.2 | 8.6 | 11.0 | 13.4 |

| 12-24 | 1.058 | 5.8 | 5.72 | 5.92 | 6.86 | 4.4 | 7.1 | 9.9 | 12.6 | 15.4 |

| 1/4-20 | 1.270 | 6.7 | 6.62 | 6.86 | 8.00 | 5.1 | 8.2 | 11.4 | 14.6 | 17.8 |

| 5/16-18 | 1.411 | 8.4 | 8.24 | 8.49 | 9.77 | 6.5 | 10.5 | 14.5 | 18.4 | 22.4 |

| 3/8-16 | 1.588 | 10.0 | 9.89 | 10.12 | 11.59 | 7.9 | 12.7 | 17.5 | 22.2 | 27.0 |

| 7/16-14 | 1.814 | 11.6 | 11.51 | 11.78 | 13.47 | 9.3 | 14.9 | 20.4 | 26.0 | 31.5 |

| 1/2-13 | 1.954 | 13.2 | 13.12 | 13.40 | 15.24 | 10.7 | 17.1 | 23.4 | 29.8 | 36.1 |

| 9/16-12 | 2.117 | 14.9 | 14.75 | 15.03 | 17.04 | 12.2 | 19.3 | 26.5 | 33.6 | 40.7 |

| 5/8-11 | 2.309 | 16.5 | 16.38 | 16.68 | 18.88 | 13.6 | 21.5 | 29.4 | 37.4 | 45.3 |

| 3/4-10 | 2.540 | 19.8 | 19.60 | 19.91 | 22.35 | 16.5 | 26.0 | 35.5 | 45.1 | 54.6 |

| 7/8-9 | 2.822 | 23.0 | 22.84 | 23.18 | 25.89 | 19.4 | 30.5 | 41.6 | 52.7 | 63.8 |

| 1″-8 | 3.175 | 26.4 | 26.09 | 26.47 | 29.53 | 22.2 | 34.9 | 47.6 | 60.3 | 73.0 |

| 1″ 1/8-7 | 3.629 | 29.5 | 29.36 | 29.74 | 33.29 | 24.9 | 39.2 | 53.2 | 67.8 | 82.0 |

| 1″ 1/4-7 | 3.629 | 32.8 | 32.54 | 32.92 | 36.46 | 28.1 | 44 | 59.9 | 75.7 | 91.6 |

| 1″ 3/8-6 | 4.234 | 36.2 | 35.84 | 36.35 | 40.42 | 30.7 | 48.2 | 65.7 | 83.0 | 100.5 |

| 1″ 1/2-6 | 4.234 | 39.5 | 39.02 | 39.53 | 43.62 | 33.9 | 52.9 | 72 | 91.0 | 110.0 |

*All information is strictly informative

Fasteners Threaded Insert Fitted (UNF) Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Threaded Insert Fitted (UNF) / Fasteners Threaded Insert Fitted (UNF)

| Nominal Diameter | Pitch (mm) | Drill Bit Diameter (mm) | Drilling Diameter | Tap | Insert Fitted | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | Min Outer Diameter | 1d | 1.5d | 2d | 2.5d | 3d | |||

| 2-64 | 0.396 | 2.3 | 2.29 | 2.44 | 2.70 | 1.8 | 2.9 | 4.0 | 5.0 | 6.2 |

| 3-56 | 0.453 | 2.7 | 2.62 | 2.77 | 3.10 | 2.0 | 3.3 | 4.6 | 5.8 | 7.1 |

| 4-48 | 0.529 | 3.0 | 2.97 | 3.14 | 3.53 | 2.3 | 3.7 | 5.2 | 6.6 | 8.0 |

| 6-40 | 0.635 | 3.8 | 3.66 | 3.81 | 4.33 | 2.9 | 4.6 | 6.4 | 8.1 | 9.9 |

| 8-36 | 0.706 | 4.4 | 4.32 | 4.47 | 5.08 | 3.4 | 5.5 | 7.6 | 9.7 | 11.8 |

| 10-32 | 0.794 | 5.1 | 5.00 | 5.16 | 5.86 | 4.0 | 6.5 | 8.9 | 11.3 | 13.7 |

| 1/4-28 | 0.907 | 6.7 | 6.55 | 6.72 | 7.53 | 5.5 | 8.6 | 11.8 | 15.0 | 18.1 |

| 5/16-24 | 1.058 | 8.3 | 8.17 | 8.35 | 9.31 | 6.9 | 10.9 | 14.9 | 18.8 | 22.7 |

| 3/8-24 | 1.058 | 9.9 | 9.75 | 9.93 | 10.90 | 8.4 | 13.2 | 18.0 | 22.8 | 27.5 |

| 7/16-20 | 1.270 | 11.5 | 11.39 | 11.59 | 12.76 | 9.8 | 15.4 | 20.9 | 26.5 | 32.0 |

| 1/2-20 | 1.270 | 13.1 | 12.97 | 13.16 | 14.35 | 11.4 | 17.8 | 24.1 | 30.5 | 36.8 |

| 9/16-18 | 1.411 | 14.7 | 14.59 | 14.79 | 16.12 | 12.9 | 20.1 | 27.2 | 34.4 | 41.4 |

| 5/8-18 | 1.411 | 16.3 | 16.18 | 16.38 | 17.71 | 14.5 | 22.4 | 30.4 | 38.3 | 46.2 |

| 3/4-16 | 1.588 | 19.5 | 19.39 | 19.60 | 21.11 | 17.5 | 27.0 | 36.5 | 46.0 | 55.6 |

| 7/8-14 | 1.814 | 22.7 | 22.62 | 22.84 | 24.58 | 20.4 | 31.5 | 42.7 | 53.8 | 64.8 |

| 1″-14 | 1.814 | 26.0 | 25.86 | 26.11 | 27.76 | 23.6 | 36.3 | 49.0 | 61.7 | 74.4 |

| 1″-12 | 2.117 | 26.0 | 25.86 | 26.11 | 28.15 | 23.3 | 36.0 | 48.7 | 61.4 | 74.0 |

| 1″ 1/8-12 | 2.117 | 29.2 | 29.03 | 29.29 | 31.33 | 26.5 | 40.7 | 55.0 | 69.3 | 83.6 |

| 1″ 1/4-12 | 2.117 | 32.4 | 32.21 | 32.21 | 34.50 | 29.7 | 45.5 | 61.4 | 77.2 | 93.1 |

| 1″ 3/8-12 | 2.117 | 35.5 | 35.38 | 35.38 | 37.68 | 32.8 | 50.3 | 67.8 | 85.2 | 102.6 |

| 1″ 1/2-12 | 2.117 | 38.7 | 38.56 | 38.56 | 40.85 | 36.0 | 55.1 | 74.1 | 93.1 | 112.2 |

*All information is strictly informative

Fasteners ISO Tolerances Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners ISO Tolerances / Fasteners ISO Tolerances

ISO Tolerances

| Nominal Dimension | Tolerance Zone in mm (External Measurements) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| over | to | m6 | h6 | h8 | h10 | h11 | h13 | h14 | h15 | h16 |

| 0 | 1 | +0.002 +0.008 | 0 -0.006 | 0 -0.014 | 0 -0.040 | 0 -0.060 | 0 -0.14 | |||

| 1 | 3 | +0.002 +0.008 | 0 -0.006 | 0 -0.014 | 0 -0.040 | 0 -0.060 | 0 -0.14 | 0 -0.25 | 0 -0.40 | 0 -0.60 |

| 3 | 6 | +0.004 +0.012 | 0 -0.008 | 0 -0.018 | 0 -0.048 | 0 -0.075 | 0 -0.18 | 0 -0.30 | 0 -0.48 | 0 -0.75 |

| 6 | 10 | +0.006 +0.015 | 0 -0.009 | 0 -0.022 | 0 -0.058 | 0 -0.090 | 0 -0.22 | 0 -0.36 | 0 -0.58 | 0 -0.90 |

| 10 | 18 | +0.007 +0.018 | 0 -0.011 | 0 -0.027 | 0 -0.070 | 0 -0.110 | 0 -0.27 | 0 -0.43 | 0 -0.70 | 0 -1.10 |

| 18 | 30 | +0.008 +0.021 | 0 -0.030 | 0 -0.033 | 0 -0.084 | 0 -0.130 | 0 -0.33 | 0 -0.52 | 0 -0.84 | 0 -1.30 |

| 30 | 50 | 0 -0.39 | 0 -0.62 | 0 -1.00 | 0 -1.60 | |||||

| 50 | 80 | 0 -0.46 | 0 -0.74 | 0 -1.20 | 0 -1.90 | |||||

| 80 | 120 | 0 -0.54 | 0 -0.87 | 0 -1.40 | 0 -2.20 | |||||

| Nominal Dimension | Tolerance Zone in mm (Internal Measurements) | ||||||

|---|---|---|---|---|---|---|---|

| over | to | H7 | H8 | H9 | H11 | H13 | H14 |

| 0 | 1 | +0.010 0 | +0.014 0 | +0.025 0 | +0.060 0 | +0.14 0 | |

| 1 | 3 | +0.010 0 | +0.014 0 | +0.025 0 | +0.060 0 | +0.14 0 | +0.25 0 |

| 3 | 6 | +0.012 0 | +0.018 0 | +0.030 0 | +0.075 0 | +0.18 0 | +0.30 0 |

| 6 | 10 | +0.015 0 | +0.022 0 | +0.036 0 | +0.090 0 | +0.22 0 | +0.36 0 |

| 10 | 18 | +0.018 0 | +0.027 0 | +0.043 0 | +0.110 0 | +0.27 0 | +0.43 0 |

| 18 | 30 | +0.021 0 | +0.033 0 | +0.052 0 | +0.130 0 | +0.33 0 | +0.52 0 |

| 30 | 50 | +0.39 0 | +0.62 0 | ||||

| 50 | 80 | +0.46 0 | +0.74 0 | ||||

| 80 | 120 | +0.54 0 | +0.87 0 | ||||

*All information is strictly informative

Fasteners Retaining Ring Interchange Chart Dimensions, Weight Chart & Material Specification & TolerancesRetaining Ring Interchange Chart / Fasteners Retaining Ring Interchange Chart

| BENERI® | ROTOR CLIP® | WALDES TRUARC® | IRR® | ANDERTON® | MIL STANDARD |

|---|---|---|---|---|---|

| 2100 – 5100 | SH | 5100 | 3100 | N1400 | 16624 |

| 2000 – 5000 | HO | N5000 | 3000 | N1300 | 16625 |

| 2160 – 5160 | SHR | 5160 | 7200 | N1460 | 3217 |

| 2108 – 5108 | SHI | 5108 | 4100 | N1408 | 16626 |

| 2008 – 5008 | HOI | 5008 | 4000 | N1308 | 16627 |

| 2101 – 5101 bowed | BSH | 5101 | 3101 | 1401 | 16628 |

| 2001 – 5001 bowed | BHO | N5001 | 3001 | 1301 | 16629 |

| BENERI® | ROTOR CLIP® | WALDES TRUARC® | IRR® | ANDERTON® | MIL STANDARD |

|---|---|---|---|---|---|

| 2133-5133 | E | 5133 | 1000 | N1500 | 16633 |

| 2144-5144 | RE | 5144 | 1200 | N1540 | 3215 |

| 2103-5103 | C | 5103 | 2000 | N1800 | 16632 |

| 2304-5304 | PO | 5304 | – | – | – |

| 2304-5304T | POL | T5304 | – | – | – |

| 2131 – 5131 bowed | BE | 5131 | 1001 | N1501 | 16634 |

| BENERI® | ROTOR CLIP® | SEEGER® | ANDERTON® |

|---|---|---|---|

| DIN 471 | DSH DIN 471 | DIN 471 A | D1400 |

| DIN 472 | DHO DIN 472 | DIN 472 J | D1300 |

| DIN 471 MAGG | DSR | DIN 471 AS | D1460 |

| DIN 472 MAGG | DHR | DIN 472 JS | D1360 |

| DIN 472 MIN | no code | no code | no code |

| DIN 472 MIN | no code | no code | no code |

| DIN 983 | DST DIN 983 | DIN 983 AK | D2100 |

| DIN 984 | DHT DIN 984 | DIN 984 JK | D2000 |

| AV | DSI | AV | M1408 |

| JV | DHI | JV | M1308 |

| AL | AL | ||

| JL | JL | ||

| SW | CFS | SW | |

| SB | CFH | SB |

| BENERI® | ROTOR CLIP® | SEEGER® | ANDERTON® |

|---|---|---|---|

| DIN 6799 | DE DIN 6799 | RA | D1500 |

| ANELLO C | DC | H | M1800 |

| ASS |

| BENERI® | ROTOR CLIP® | SEEGER® | ANDERTON® |

|---|---|---|---|

| RESS | DTX | ZA | M1465 |

| Ress x fori | DTI | ZJ | M1365 |

| AESS | DSF | G |

Fasteners Basic Metric Thread Chart (M1 – M100) Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Basic Metric Thread Chart (M1 – M100) / Fasteners Basic Metric Thread Chart (M1 – M100)

Basic Metric Thread Chart (M1 – M100)

| Diameter | Coarse Pitch | Fine Thread Pitches | ||

|---|---|---|---|---|

| M1 | 0.25 | 0.2 | ||

| M1.2 | 0.25 | 0.2 | ||

| M1.4 | 0.3 | 0.2 | ||

| M1.6 | 0.35 | 0.2 | ||

| M1.7 | 0.35 | |||

| M1.8 | 0.35 | 0.2 | ||

| M2 | 0.4 | 0.25 | ||

| M2.2 | 0.45 | 0.25 | ||

| M2.3 | 0.4 | |||

| M2.5 | 0.45 | 0.35 | ||

| M2.6 | 0.45 | |||

| M3 | 0.5 | 0.35 | ||

| M3.5 | 0.6 | 0.35 | ||

| M4 | 0.7 | 0.5 | ||

| M5 | 0.8 | 0.5 | ||

| M6 | 1 | 0.75 | ||

| M7 | 1 | 0.75 | ||

| M8 | 1.25 | 1 | 0.75 | |

| M9 | 1.25 | 1 | 0.75 | |

| M10 | 1.5 | 1.25 | 1 | 0.75 |

| M11 | 1.5 | 1 | 0.75 | |

| M12 | 1.75 | 1.5 | 1.25 | 1 |

| M14 | 2 | 1.5 | 1.25 | 1 |

| M16 | 2 | 1.5 | 1 | |

| M18 | 2.5 | 2 | 1.5 | 1 |

| M20 | 2.5 | 2 | 1.5 | 1 |

| M22 | 2.5 | 2 | 1.5 | 1 |

| M24 | 3 | 2 | 1.5 | 1 |

| M27 | 3 | 2 | 1.5 | 1 |

| M30 | 3.5 | 3 | 2 | 1.5 |

| M33 | 3.5 | 3 | 2 | 1.5 |

| M36 | 4 | 3 | 2 | 1.5 |

| M39 | 4 | 3 | 2 | 1.5 |

| M42 | 4.5 | 4 | 3 | 2 |

| M45 | 4.5 | 4 | 3 | 2 |

| M48 | 5 | 4 | 3 | 2 |

| M52 | 5 | 4 | 3 | 2 |

| M56 | 5.5 | 4 | 3 | 2 |

| M60 | 5.5 | 4 | 3 | 2 |

| M64 | 6 | 4 | 3 | 2 |

| M68 | 6 | 4 | 3 | 2 |

| M72 | 6 | 4 | 3 | 2 |

| M80 | 6 | 4 | 3 | 2 |

| M90 | 6 | 4 | 3 | 2 |

| M100 | 6 | 4 | 3 | 2 |

*All information is strictly informative

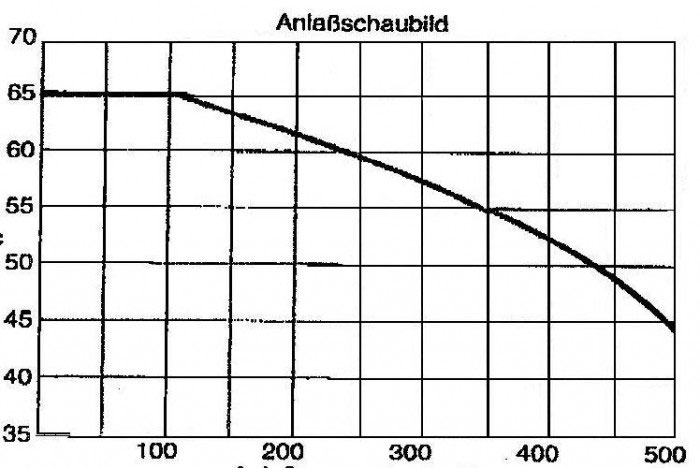

Drill Rod Dimensions, Weight Chart & Material Specification & Tolerances / Drill Rod / Drill Rod

Specifications for Drill Rod

Alloy Tool Steel Drill RodCR-V Alloy Silversteel

115 Cr V3

Steel Nr. 1.2210

| Properties Cr-V-alloyed tool steel with high strength Maintains blade sharpness Good machinability when spheroidized-annealed Small distortion on oil hardening (possible up to approx. 9mm) | Chemical Analysis | ||

|---|---|---|---|

| C | 1.15% | ||

| Cr | 0.70% | ||

| V | 0.10% | ||

| Si | 0.25% | ||

| Mn | 0.30% | ||

| Examples of Applications Twist drills and thread taps, reamers, piercing dies, ejectors, arbors, engraving tools, scrapers, files, etc.Is preferably used with silver steel finish in smallest tolerances | |||

| Delivery Conditions Spheroidized-annealed, drawn, ground and polished | Annealed tensile strength Max 750 N/mm2 (220HB) | ||

| Heat Treatment | |

|---|---|

| Hot Shaping -> | 1050-850 degrees C |

| Soft Annealing Temperature -> | 710-750 degrees C |

| Hardening Temperature -> | 810-840 degrees C in oil |

| 780-810 degrees C in water | |

| Hardness in HRC | Annealing Temperature in degrees Celsius | |

|---|---|---|

| Nomimal Dimension | Tolerance Zone in mm (external measurements) | ||

|---|---|---|---|

| Over | To | h8 (Steel) | |

| 0 | 1 | 0 | -0.014 |

| 1 | 3 | 0 | -0.014 |

| 3 | 6 | 0 | -0.018 |

| 6 | 10 | 0 | -0.022 |

| 10 | 18 | 0 | -0.027 |

| 18 | 30 | 0 | -0.033 |

| Nomimal Dimension | Tolerance Zone in mm (external measurements) | ||

|---|---|---|---|

| Over | To | h9 (Stainless Steel) | |

| 1 | 3 | 0 | -0.025 |

| 3 | 6 | 0 | -0.030 |

| 6 | 10 | 0 | -0.036 |

| 10 | 18 | 0 | -0.043 |

| 18 | 30 | 0 | -0.052 |

Threaded Insert Outer Diameter In The Free State (UNC) Dimensions, Weight Chart & Material Specification & Tolerances / Threaded Insert Outer Diameter In The Free State (UNC) / Threaded Insert Outer Diameter In The Free State (UNC)

Threaded Insert Outer Diameter In The Free State (UNC)

| Nominal Diameter | Pitch (mm) | Drill Bit Diameter (mm) | Drilling Diameter | Tap | Outer Diameter In The Free State | ||

|---|---|---|---|---|---|---|---|

| min. | max. | Min Outer Diameter | min | max | |||

| 2-56 | 0.453 | 2.4 | 2.30 | 2.50 | 2.77 | 2.8 | 3.0 |

| 3-48 | 0.529 | 2.7 | 2.65 | 2.80 | 3.20 | 3.2 | 3.5 |

| 4-40 | 0.635 | 3.1 | 3.00 | 3.15 | 3.67 | 3.6 | 4.0 |

| 5-40 | 0.635 | 3.4 | 3.33 | 3.50 | 4.00 | 4.0 | 4.4 |

| 6-32 | 0.794 | 3.8 | 3.68 | 3.89 | 4.54 | 4.5 | 4.9 |

| 8-32 | 0.794 | 4.4 | 4.34 | 4.52 | 5.20 | 5.2 | 5.6 |

| 10-24 | 1.058 | 5.2 | 5.06 | 5.28 | 6.20 | 6.2 | 6.6 |

| 12-24 | 1.058 | 5.8 | 5.72 | 5.92 | 6.86 | 6.8 | 7.2 |

| 1/4-20 | 1.270 | 6.7 | 6.62 | 6.86 | 8.00 | 8.0 | 8.4 |

| 5/16-18 | 1.411 | 8.4 | 8.24 | 8.49 | 9.77 | 9.7 | 10.2 |

| 3/8-16 | 1.588 | 10.0 | 9.89 | 10.12 | 11.59 | 11.5 | 12.0 |

| 7/16-14 | 1.814 | 11.6 | 11.51 | 11.78 | 13.47 | 13.4 | 14.0 |

| 1/2-13 | 1.954 | 13.2 | 13.12 | 13.40 | 15.24 | 15.2 | 15.8 |

| 9/16-12 | 2.117 | 14.9 | 14.75 | 15.03 | 17.04 | 17.0 | 17.6 |

| 5/8-11 | 2.309 | 16.5 | 16.38 | 16.68 | 18.88 | 18.9 | 19.5 |

| 3/4-10 | 2.540 | 19.8 | 19.60 | 19.91 | 22.35 | 22.4 | 23.0 |

| 7/8-9 | 2.822 | 23.0 | 22.84 | 23.18 | 25.89 | 26.0 | 26.7 |

| 1″-8 | 3.175 | 26.4 | 26.09 | 26.47 | 29.53 | 29.6 | 30.4 |

| 1″ 1/8-7 | 3.629 | 29.5 | 29.36 | 29.74 | 33.29 | 33.4 | 34.4 |

| 1″ 1/4-7 | 3.629 | 32.8 | 32.54 | 32.92 | 36.46 | 36.7 | 37.7 |

| 1″ 3/8-6 | 4.234 | 36.2 | 35.84 | 36.35 | 40.42 | 40.6 | 41.7 |

| 1″ 1/2-6 | 4.234 | 39.5 | 39.02 | 39.53 | 43.62 | 43.9 | 45.0 |

*All information is strictly informative

Threaded Insert Outer Diameter In The Free State (UNF) Dimensions, Weight Chart & Material Specification & TolerancesThreaded Insert Outer Diameter In The Free State (UNF) / Threaded Insert Outer Diameter In The Free State (UNF)

Threaded Insert Outer Diameter In The Free State (UNF)

| Nominal Diameter | Pitch (mm) | Drill Bit Diameter (mm) | Drilling Diameter | Tap | Outer Diameter In The Free State | ||

|---|---|---|---|---|---|---|---|

| min. | max. | Min Outer Diameter | min | max | |||

| 2-64 | 0.396 | 2.3 | 2.29 | 2.44 | 2.70 | 2.79 | 3.02 |

| 3-56 | 0.453 | 2.7 | 2.62 | 2.77 | 3.10 | 3.3 | 3.7 |

| 4-48 | 0.529 | 3.0 | 2.97 | 3.14 | 3.53 | 3.7 | 4.1 |

| 6-40 | 0.635 | 3.8 | 3.66 | 3.81 | 4.33 | 4.5 | 4.9 |

| 8-36 | 0.706 | 4.4 | 4.32 | 4.47 | 5.08 | 5.3 | 5.7 |

| 10-32 | 0.794 | 5.1 | 5.00 | 5.16 | 5.86 | 6.1 | 6.5 |

| 1/4-28 | 0.907 | 6.7 | 6.55 | 6.72 | 7.53 | 7.8 | 8.3 |

| 5/16-24 | 1.058 | 8.3 | 8.17 | 8.35 | 9.31 | 9.7 | 10.2 |

| 3/8-24 | 1.058 | 9.9 | 9.75 | 9.93 | 10.90 | 11.4 | 11.9 |

| 7/16-20 | 1.270 | 11.5 | 11.39 | 11.59 | 12.76 | 13.4 | 13.9 |

| 1/2-20 | 1.270 | 13.1 | 12.97 | 13.16 | 14.35 | 15.1 | 15.7 |

| 9/16-18 | 1.411 | 14.7 | 14.59 | 14.79 | 16.12 | 16.9 | 17.6 |

| 5/8-18 | 1.411 | 16.3 | 16.18 | 16.38 | 17.71 | 18.6 | 19.3 |

| 3/4-16 | 1.588 | 19.5 | 19.39 | 19.60 | 21.11 | 22.2 | 22.9 |

| 7/8-14 | 1.814 | 22.7 | 22.62 | 22.84 | 24.58 | 26.0 | 26.7 |

| 1″-14 | 1.814 | 26.0 | 25.86 | 26.11 | 27.76 | 29.4 | 30.1 |

| 1″-12 | 2.117 | 26.0 | 25.86 | 26.11 | 28.15 | 29.7 | 30.4 |

| 1″ 1/8-12 | 2.117 | 29.2 | 29.03 | 29.29 | 31.33 | 33.2 | 33.9 |

| 1″ 1/4-12 | 2.117 | 32.4 | 32.21 | 32.21 | 34.50 | 36.6 | 37.3 |

| 1″ 3/8-12 | 2.117 | 35.5 | 35.38 | 35.38 | 37.68 | 40.0 | 40.9 |

| 1″ 1/2-12 | 2.117 | 38.7 | 38.56 | 38.56 | 40.85 | 43.4 | 44.3 |

*All information is strictly informative

Threaded Insert Number Of Coils In The Free State (UNF) / Threaded Insert Number Of Coils In The Free State (UNF) / Threaded Insert Number Of Coils In The Free State (UNF) / Threaded Insert Number Of Coils In The Free State (UNF)

| Nominal Diameter | Pitch (mm) | Drill Bit Diameter (mm) | Drilling Diameter | Tap | Number Of Coils In The Free State | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | Min Outer Diameter | 1d | 1.5d | 2d | 2.5d | 3d | |||

| 2-64 | 0.396 | 2.3 | 2.29 | 2.44 | 2.70 | 3.5 | 5.6 | 8.0 | 10.4 | 12.5 |

| 3-56 | 0.453 | 2.7 | 2.62 | 2.77 | 3.10 | 3.4 | 5.6 | 8.0 | 10.4 | 12.6 |

| 4-48 | 0.529 | 3.0 | 2.97 | 3.14 | 3.53 | 3.4 | 5.6 | 7.9 | 10.2 | 12.5 |

| 6-40 | 0.635 | 3.8 | 3.66 | 3.81 | 4.33 | 3.8 | 6.0 | 8.4 | 10.8 | 13.2 |

| 8-36 | 0.706 | 4.4 | 4.32 | 4.47 | 5.08 | 4.0 | 6.6 | 9.1 | 11.7 | 14.2 |

| 10-32 | 0.794 | 5.1 | 5.00 | 5.16 | 5.86 | 4.1 | 6.8 | 9.5 | 12.1 | 14.9 |

| 1/4-28 | 0.907 | 6.7 | 6.55 | 6.72 | 7.53 | 5.0 | 8.1 | 11.3 | 14.4 | 17.6 |

| 5/16-24 | 1.058 | 8.3 | 8.17 | 8.35 | 9.31 | 5.5 | 8.9 | 12.2 | 15.6 | 19.0 |

| 3/8-24 | 1.058 | 9.9 | 9.75 | 9.93 | 10.90 | 6.9 | 10.9 | 14.9 | 19.0 | 23.2 |

| 7/16-20 | 1.270 | 11.5 | 11.39 | 11.59 | 12.76 | 6.6 | 10.6 | 14.5 | 18.4 | 22.5 |

| 1/2-20 | 1.270 | 13.1 | 12.97 | 13.16 | 14.35 | 7.8 | 12.3 | 16.8 | 21.3 | 25.9 |

| 9/16-18 | 1.411 | 14.7 | 14.59 | 14.79 | 16.12 | 7.9 | 12.5 | 17.1 | 21.6 | 26.2 |

| 5/8-18 | 1.411 | 16.3 | 16.18 | 16.38 | 17.71 | 8.9 | 14.1 | 19.1 | 24.3 | 29.4 |

| 3/4-16 | 1.588 | 19.5 | 19.39 | 19.60 | 21.11 | 9.7 | 15.1 | 20.6 | 26.0 | 31.5 |

| 7/8-14 | 1.814 | 22.7 | 22.62 | 22.84 | 24.58 | 9.9 | 15.4 | 21.0 | 26.6 | 32.2 |

| 1″-14 | 1.814 | 26.0 | 25.86 | 26.11 | 27.76 | 11.5 | 17.9 | 24.3 | 30.6 | 37.0 |

| 1″-12 | 2.117 | 26.0 | 25.86 | 26.11 | 28.15 | 9.7 | 15.1 | 20.6 | 26.1 | 31.5 |

| 1″ 1/8-12 | 2.117 | 29.2 | 29.03 | 29.29 | 31.33 | 11.1 | 17.3 | 23.4 | 29.6 | 35.7 |

| 1″ 1/4-12 | 2.117 | 32.4 | 32.21 | 32.21 | 34.50 | 12.4 | 19.3 | 26.1 | 33.0 | 39.8 |

| 1″ 3/8-12 | 2.117 | 35.5 | 35.38 | 35.38 | 37.68 | 13.8 | 21.3 | 28.9 | 36.5 | 44.0 |

| 1″ 1/2-12 | 2.117 | 38.7 | 38.56 | 38.56 | 40.85 | 15.2 | 23.4 | 31.6 | 39.8 | 48.2 |

*All information is strictly informative

Threaded Insert Number Of Coils In The Free State (Metric)Threaded Insert Number Of Coils In The Free State (Metric)Threaded Insert Number Of Coils In The Free State (Metric)

| Nominal Diameter | Pitch (mm) | Drill Bit Diameter (mm) | Drilling Diameter | Tap | Number of Coils in the Free State | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | Min Outer Diameter | 0.5d | 0.75d | 1d | 1.5d | 2d | 2.5d | 3d | |||

| M2 | 0.4 | 2.1 | 2.09 | 2.18 | 2.52 | – | – | 3.5 | 5.9 | 7.8 | 10.0 | 12.0 |

| M2.5 | 0.45 | 2.6 | 2.60 | 2.70 | 3.08 | – | – | 3.5 | 5.9 | 8.1 | 10.5 | 12.9 |

| M3 | 0.5 | 3.2 | 3.11 | 3.22 | 3.65 | – | – | 3.9 | 6.3 | 8.7 | 11.1 | 13.5 |

| M3.5 | 0.6 | 3.7 | 3.63 | 3.76 | 4.28 | – | – | 3.7 | 6.3 | 8.7 | 11.2 | 13.3 |

| M4 | 0.7 | 4.2 | 4.15 | 4.29 | 4.91 | – | – | 3.7 | 6.1 | 8.4 | 10.9 | 13.2 |

| M5 | 0.8 | 5.2 | 5.17 | 5.33 | 6.04 | – | – | 4.3 | 6.9 | 9.7 | 12.3 | 14.8 |

| M6 | 1.0 | 6.3 | 6.22 | 6.41 | 7.30 | – | – | 4.2 | 6.9 | 9.6 | 12.3 | 14.6 |

| M7 | 1.0 | 7.3 | 7.22 | 7.41 | 8.30 | – | – | 5.3 | 8.2 | 11.1 | 14.3 | 17.4 |

| M8x1 | 1.0 | 8.3 | 8.22 | 8.41 | 9.30 | – | – | 6.1 | 9.5 | 12.9 | 16.5 | 19.9 |

| M8 | 1.25 | 8.4 | 8.27 | 8.48 | 9.62 | – | – | 4.7 | 7.4 | 10.6 | 13.5 | 16.4 |

| M9 | 1.25 | 9.4 | 9.27 | 9.48 | 10.62 | – | – | 5.3 | 8.6 | 11.9 | 15.3 | 18.1 |

| M10x1 | 1.0 | 10.25 | 10.22 | 10.41 | 11.30 | – | – | 7.6 | 12.1 | 16.3 | 20.7 | 25.0 |

| M10x1.25 | 1.25 | 10.4 | 10.27 | 10.48 | 11.62 | – | – | 6.0 | 9.7 | 13.1 | 16.9 | 20.1 |

| M10 | 1.5 | 10.5 | 10.32 | 10.56 | 11.95 | – | – | 5.0 | 8.1 | 11.2 | 14.2 | 17.2 |

| M11 | 1.5 | 11.5 | 11.32 | 11.56 | 12.95 | – | – | 5.6 | 9.0 | 12.3 | 15.7 | 18.9 |

| M12x1 | 1.0 | 12.3 | 12.22 | 12.41 | 13.30 | – | – | 9.3 | 14.5 | 19.5 | 24.8 | 30.0 |

| M12x1.25 | 1.25 | 12.4 | 12.27 | 12.48 | 13.62 | – | – | 7.4 | 11.6 | 15.9 | 20.7 | 24.8 |

| M12x1.5 | 1.5 | 12.5 | 12.32 | 12.56 | 13.95 | – | – | 6.2 | 9.8 | 13.5 | 15.7 | 20.8 |

| M12 | 1.75 | 12.5 | 12.38 | 12.64 | 14.27 | – | – | 5.2 | 8.4 | 11.7 | 14.7 | 18.0 |