Fasteners Specifications

Fasteners E Rings for Shafts, Fasteners External Shafts Rings, Fasteners Threaded Insert Outer Diameter In The Free State (Metric) Dimensions

Fasteners Stainless Steel Data Dimensions, Stainless Steel 303 304 316 Properties, Mechanical Properties-Austenitic Grades - Bolts, Screws and Studs, Comparison: US and ISO (DIN) Stainless Steels, Selection of Diameters - Tightening Torques, Loads, Comparative International Stainless Steel Grades, Thread Identification Chart (American Standard), Thread Identification Chart (Metric – Coarse/Fine)

Table of Content

Table of Content

Fasteners E Rings for Shafts

Fasteners External Shafts Rings

Fasteners Threaded Insert Outer Diameter In The Free State (Metric) Dimensions

Fasteners Stainless Steel Data Dimensions

Stainless Steel 303 304 316 Properties

Mechanical Properties-Austenitic Grades - Bolts, Screws and Studs

Comparison: US and ISO (DIN) Stainless Steels

Selection of Diameters - Tightening Torques, Loads

Comparative International Stainless Steel Grades

Thread Identification Chart (American Standard)

Thread Identification Chart (Metric – Coarse/Fine)

Fasteners Torque Information Dimensions

General Torque Figures

Torque – Metric Fasteners

Torque – Imperial Fasteners

ISO Metric (Coarse) Threads Dimensions

Proof Loads For Screws - ISO Metric (Fine) Threads ISO 898/I-1988

Proof Loads For Nuts (Coarse Thread) - According to DIN 934 and DIN 985

Proof Loads For Nuts (Fine Thread) - According to DIN 934 and DIN 985

Chemical Resistance Table For Screws in A2 and A4

Thread Identification Chart (British)

Retaining Ring (Heavy Duty ) Series 2160-5160 Specifications

DIN / ISO / EN Crossover Chart

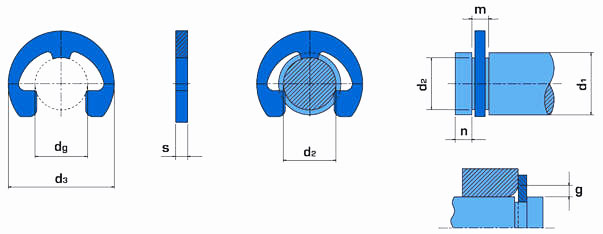

Fasteners E Rings for Shafts (Heavy Duty) Series 2144-5144 Specifications Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners E Rings for Shafts (Heavy Duty) Series 2144-5144 Specifications / Fasteners E Rings for Shafts (Heavy Duty) Series 2144-5144 Specifications

E Rings for Shafts (Heavy Duty) Series 2144-5144 Specifications

All measurements in millimeters (mm)

| Ring n° | d2 | d3 ref. | s | dg | d1 | m | n min. | FN Lbr. | Fs Lbr. | g | Fsg Lib. | nabl min. | lbs | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 9 | 0.074 | +0.002 | 0.206 | 0.015 | +0.002 | 0.072 | +0.001 | 0.094 | 0.020 | +0.002 | 0.020 | 13 | 51 | 0.033 | 50 | 90000 | 0.073 |

| -0.000 | -0.002 | -0.003 | -0.000 | ||||||||||||||

| 12 | 0.095 | +0.002 | 0.270 | 0.015 | +0.002 | 0.093 | +0.001 | 0.125 | 0.020 | +0.002 | 0.030 | 25 | 76 | 0.033 | 75 | 70000 | 0.125 |

| -0.000 | -0.002 | -0.003 | -0.000 | ||||||||||||||

| 15 | 0.116 | +0.002 | 0.335 | 0.025 | +0.002 | 0.113 | +0.002 | 0.156 | 0.029 | +0.003 | 0.040 | 40 | 152 | 0.050 | 150 | 60000 | 0.308 |

| -0.000 | -0.002 | -0.003 | -0.000 | ||||||||||||||

| 18 | 0.147 | +0.002 | 0.375 | 0.025 | +0.002 | 0.143 | +0.003 | 0.188 | 0.029 | +0.003 | 0.040 | 50 | 183 | 0.050 | 180 | 50000 | 0.396 |

| -0.000 | -0.002 | -0.003 | -0.000 | ||||||||||||||

| 21 | 0.188 | +0.002 | 0.446 | 0.025 | +0.002 | 0.182 | +0.003 | 0.219 | 0.029 | +0.003 | 0.031 | 50 | 223 | 0.050 | 220 | 43000 | 0.506 |

| -0.002 | -0.002 | -0.003 | -0.000 | ||||||||||||||

| 25 | 0.210 | +0.002 | 0.516 | 0.025 | +0.002 | 0.204 | +0.003 | 0.250 | 0.029 | +0.003 | 0.040 | 75 | 254 | 0.050 | 250 | 38000 | 0.704 |

| -0.002 | -0.002 | -0.003 | -0.000 | ||||||||||||||

| 31 | 0.250 | +0.003 | 0.588 | 0.025 | +0.002 | 0.242 | +0.003 | 0.312 | 0.029 | +0.003 | 0.062 | 135 | 305 | 0.055 | 300 | 32000 | 0.915 |

| -0.003 | -0.002 | -0.003 | -0.000 | ||||||||||||||

| 37 | 0.303 | +0.003 | 0.660 | 0.035 | +0.002 | 0.292 | +0.004 | 0.375 | 0.039 | +0.003 | 0.072 | 190 | 528 | 0.055 | 520 | 28000 | 1.525 |

| -0.003 | -0.002 | -0.004 | -0.000 | ||||||||||||||

| 43 | 0.343 | +0.003 | 0.746 | 0.035 | +0.00 | 0.332 | +0.004 | 0.438 | 0.039 | +0.003 | 0.094 | 285 | 609 | 0.055 | 600 | 24000 | 2.024 |

| -0.003 | -0.002 | -0.004 | -0.000 | ||||||||||||||

| 50 | 0.396 | +0.003 | 0.810 | 0.042 | +0.002 | 0.385 | +0.004 | 0.500 | 0.046 | +0.003 | 0.104 | 360 | 832 | 0.060 | 820 | 20000 | 2.640 |

| -0.003 | -0.002 | -0.004 | -0.000 | ||||||||||||||

| 56 | 0.437 | +0.003 | 0.870 | 0.042 | +0.002 | 0.430 | +0.004 | 0.562 | 0.046 | +0.003 | 0.124 | 480 | 944 | 0.060 | 930 | 17000 | 2.904 |

| -0.003 | -0.002 | -0.004 | -0.000 | ||||||||||||||

*All information is strictly informative

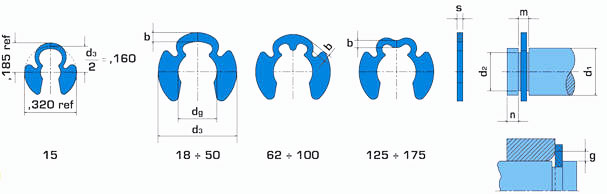

Fasteners External Shafts Rings (Poodle Style) Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners External Shafts Rings (Poodle Style) / Fasteners External Shafts Rings (Poodle Style)

All measurements in millimeters (mm)

| Ring n° | d2 | d3 ref. | s | dg | b | d1 | m | n min. | FN Lbr. | Fs Lbr. | g | Fsg Lib. | nabl min. | lbs | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 0.120 | +0.004 | 0.320 | 0.035 | +0.002 | 0.110 | +0.003 | 0.042 | 0.156 | 0.039 | +0.006 | 0.036 | 110 | 457 | 0.040 | 250 | 80000 | 0.418 |

| -0.004 | -0.002 | -0.003 | -0.000 | |||||||||||||||

| 18 | 0.148 | +0.005 | 0.400 | 0.035 | +0.002 | 0.140 | +0.003 | 0.048 | 0.188 | 0.039 | +0.006 | 0.040 | 130 | 609 | 0.040 | 270 | 80000 | 0.594 |

| -0.005 | -0.002 | -0.003 | -0.000 | |||||||||||||||

| 25 | 0.210 | +0.006 | 0.482 | 0.035 | +0.002 | 0.188 | +0.003 | 0.058 | 0.250 | 0.039 | +0.006 | 0.040 | 200 | 914 | 0.040 | 310 | 65000 | 0.878 |

| -0.006 | -0.002 | -0.003 | -0.000 | |||||||||||||||

| 31 | 0.272 | +0.006 | 0.588 | 0.042 | +0.002 | 0.250 | +0.003 | 0.074 | 0.312 | 0.046 | +0.006 | 0.040 | 250 | 1320 | 0.050 | 400 | 65000 | 1.518 |

| -0.006 | -0.002 | -0.003 | -0.000 | |||||||||||||||

| 37 | 0.331 | +0.006 | 0.680 | 0.042 | +0.002 | 0.312 | +0.004 | 0.081 | 0.375 | 0.046 | +0.006 | 0.044 | 300 | 1573 | 0.050 | 430 | 65000 | 2.002 |

| -0.006 | -0.002 | -0.004 | -0.000 | |||||||||||||||

| 43 | 0.390 | +0.008 | 0.752 | 0.050 | +0.002 | 0.375 | +0.004 | 0.081 | 0.438 | 0.056 | +0.006 | 0.048 | 400 | 2233 | 0.060 | 600 | 60000 | 2.684 |

| -0.008 | -0.002 | -0.004 | -0.000 | |||||||||||||||

| 50 | 0.440 | +0.008 | 0.826 | 0.050 | +0.002 | 0.406 | +0.004 | 0.097 | 0.500 | 0.056 | +0.006 | 0.060 | 600 | 2538 | 0.060 | 630 | 50000 | 3.322 |

| -0.008 | -0.002 | -0.004 | -0.000 | |||||||||||||||

| 62 | 0.531 | +0.008 | 0.966 | 0.050 | +0.002 | 0.500 | +0.005 | 0.086 | 0.625 | 0.056 | +0.006 | 0.094 | 1100 | 3045 | 0.060 | 720 | 45000 | 3.322 |

| -0.008 | -0.002 | -0.005 | -0.000 | |||||||||||||||

| 75 | 0.632 | +0.010 | 1.095 | 0.062 | +0.003 | 0.594 | +0.005 | 0.095 | 0.750 | 0.068 | +0.008 | 0.118 | 1600 | 4669 | 0.065 | 1000 | 38000 | 6.688 |

| -0.010 | -0.003 | -0.005 | -0.000 | |||||||||||||||

| 100 | 0.860 | +0.010 | 1.415 | 0.078 | +0.003 | 0.812 | +0.006 | 0.113 | 1.000 | 0.086 | +0.008 | 0.140 | 2600 | 7613 | 0.065 | 1800 | 25000 | 13.024 |

| -0.010 | -0.003 | -0.006 | -0.000 | |||||||||||||||

| 125 | 1.090 | +0.010 | 1.800 | 0.093 | +0.003 | 1.032 | +0.006 | 0.180 | 1.250 | 0.103 | +0.008 | 0.160 | 3500 | 11165 | 0.065 | 2750 | 11000 | 25.498 |

| -0.010 | -0.003 | -0.006 | -0.000 | |||||||||||||||

LINKS HERE

*All information is strictly informative

Fasteners Threaded Insert Outer Diameter In The Free State (Metric) Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Threaded Insert Outer Diameter In The Free State (Metric) / Fasteners Threaded Insert Outer Diameter In The Free State (Metric)

Threaded Insert Outer Diameter In The Free State (Metric)

| Nominal Diameter | Pitch (mm) | Drill Bit Diameter (mm) | Drilling Diameter | Tap | Outer Diameter in Free State | ||

|---|---|---|---|---|---|---|---|

| min. | max. | Min Outer Diameter | Min | Max | |||

| M2 | 0.4 | 2.1 | 2.09 | 2.18 | 2.52 | 2.5 | 2.7 |

| M2.5 | 0.45 | 2.6 | 2.60 | 2.70 | 3.08 | 3.3 | 3.5 |

| M3 | 0.5 | 3.2 | 3.11 | 3.22 | 3.65 | 3.8 | 4.0 |

| M3.5 | 0.6 | 3.7 | 3.63 | 3.76 | 4.28 | 4.55 | 4.75 |

| M4 | 0.7 | 4.2 | 4.15 | 4.29 | 4.91 | 5.15 | 5.35 |

| M5 | 0.8 | 5.2 | 5.17 | 5.33 | 6.04 | 6.35 | 6.6 |

| M6 | 1.0 | 6.3 | 6.22 | 6.41 | 7.30 | 7.6 | 7.85 |

| M7 | 1.0 | 7.3 | 7.22 | 7.41 | 8.30 | 8.65 | 8.9 |

| M8x1 | 1.0 | 8.3 | 8.22 | 8.41 | 9.30 | 9.85 | 10.1 |

| M8 | 1.25 | 8.4 | 8.27 | 8.48 | 9.62 | 9.85 | 10.1 |

| M9 | 1.25 | 9.4 | 9.27 | 9.48 | 10.62 | 10.85 | 11.1 |

| M10x1 | 1.0 | 10.25 | 10.22 | 10.41 | 11.30 | 12.1 | 12.5 |

| M10x1.25 | 1.25 | 10.4 | 10.27 | 10.48 | 11.62 | 12.1 | 12.5 |

| M10 | 1.5 | 10.5 | 10.32 | 10.56 | 11.95 | 12.1 | 12.5 |

| M11 | 1.5 | 11.5 | 11.32 | 11.56 | 12.95 | 13.1 | 13.5 |

| M12x1 | 1.0 | 12.3 | 12.22 | 12.41 | 13.30 | 14.4 | 14.8 |

| M12x1.25 | 1.25 | 12.4 | 12.27 | 12.48 | 13.62 | 14.4 | 14.8 |

| M12x1.5 | 1.5 | 12.5 | 12.32 | 12.56 | 13.95 | 14.4 | 14.8 |

| M12 | 1.75 | 12.5 | 12.38 | 12.64 | 14.27 | 14.4 | 14.8 |

| M14x1.25 | 1.25 | 14.4 | 14.27 | 14.48 | 15.62 | 17.2 | 17.7 |

| M14x1.5 | 1.5 | 14.5 | 14.32 | 14.56 | 15.95 | 17.2 | 17.7 |

| M14 | 2.0 | 14.5 | 14.43 | 14.73 | 16.60 | 17.2 | 17.7 |

| M16x1.5 | 1.5 | 16.5 | 16.32 | 16.56 | 17.95 | 19.4 | 19.9 |

| M16 | 2.0 | 16.5 | 16.43 | 16.73 | 18.60 | 19.4 | 19.9 |

| M18x1.5 | 1.5 | 18.5 | 18.32 | 18.56 | 19.95 | 21.5 | 22.0 |

| M18x2 | 2.0 | 18.5 | 18.43 | 18.73 | 20.60 | 21.5 | 22.0 |

| M18 | 2.5 | 18.75 | 18.54 | 18.90 | 21.25 | 21.5 | 22.0 |

| M20x1.5 | 1.5 | 20.5 | 20.32 | 20.56 | 21.95 | 23.7 | 24.2 |

| M20x2 | 2.0 | 20.5 | 20.43 | 20.73 | 22.60 | 23.7 | 24.2 |

| M20 | 2.5 | 20.75 | 20.54 | 20.90 | 23.25 | 23.7 | 24.2 |

| M22x1.5 | 1.5 | 22.5 | 22.32 | 22.56 | 23.95 | 26.3 | 26.8 |

| M22x2 | 2.0 | 22.5 | 22.43 | 22.73 | 24.60 | 26.3 | 26.8 |

| M22 | 2.5 | 22.75 | 22.54 | 22.90 | 25.25 | 26.3 | 26.8 |

| M24x1.5 | 1.5 | 24.5 | 24.32 | 24.56 | 25.95 | 28.6 | 29.1 |

| M24x2 | 2.0 | 24.5 | 24.43 | 24.73 | 26.60 | 28.6 | 29.1 |

| M24 | 3.0 | 24.75 | 24.65 | 25.05 | 27.90 | 28.6 | 29.1 |

| M26x1.5 | 1.5 | 26.5 | 26.32 | 26.56 | 27.95 | 31.0 | 31.5 |

| M27x1.5 | 1.5 | 27.5 | 27.32 | 27.56 | 28.95 | 32.2 | 32.7 |

| M27x2 | 2.0 | 27.5 | 27.43 | 27.73 | 29.60 | 32.2 | 32.7 |

| M27 | 3.0 | 27.75 | 27.65 | 28.05 | 30.90 | 32.2 | 32.7 |

| M28x1.5 | 1.5 | 28.5 | 28.32 | 28.56 | 29.95 | 33.1 | 33.6 |

| M30x1.5 | 1.5 | 30.5 | 30.22 | 30.56 | 31.95 | 35.2 | 35.7 |

| M30x2 | 2.0 | 30.5 | 30.43 | 30.73 | 32.60 | 35.2 | 35.7 |

| M30 | 3.5 | 31.0 | 30.76 | 31.21 | 34.55 | 35.2 | 35.7 |

| M33x2 | 2.0 | 33.5 | 33.43 | 33.73 | 35.60 | 38.3 | 38.8 |

| M33 | 3.5 | 34.0 | 33.76 | 34.21 | 37.55 | 38.3 | 38.8 |

| M34x1.5 | 1.5 | 34.5 | 34.32 | 34.56 | 35.95 | 39.1 | 39.4 |

| M36x1.5 | 1.5 | 36.5 | 36.32 | 36.56 | 37.95 | 42.1 | 42.6 |

| M36x2 | 2.0 | 36.5 | 36.43 | 36.73 | 38.60 | 42.1 | 42.6 |

| M36x3 | 3.0 | 37.0 | 36.65 | 37.05 | 39.90 | 42.1 | 42.6 |

| M36 | 4.0 | 37.0 | 36.87 | 37.34 | 41.20 | 42.1 | 42.6 |

| M39x3 | 3.0 | 40.0 | 39.65 | 40.05 | 42.90 | 45.1 | 45.6 |

| M39 | 4.0 | 40.0 | 39.87 | 40.34 | 44.20 | 45.1 | 45.6 |

| M42x3 | 3.0 | 43.0 | 42.65 | 43.05 | 45.90 | 48.5 | 49.0 |

| M42 | 4.5 | 43.0 | 42.98 | 43.50 | 47.85 | 48.5 | 49.0 |

| M45x3 | 3.0 | 46.0 | 45.65 | 46.05 | 48.90 | 52.00 | 52.5 |

| M45 | 4.5 | 46.0 | 45.98 | 46.50 | 50.85 | 53.5 | 54.0 |

*All information is strictly informative

Fasteners Stainless Steel Data Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Stainless Steel Data / Fasteners Stainless Steel Data

Stainless Steel Data

Designation System for Stainless Steel (ISO 3506 1979)

| Composition Groups | Austenitic | Ferritic | Martensitic | |||||

|---|---|---|---|---|---|---|---|---|

| Identification of Steel Grades | A1, A2, A4 | F1 | C1, C4 | C3 | ||||

| Property Class | 50 | 70 | 80 | 45 | 60 | 50 | 70 | 80 |

| Soft | Cold-Worked | High-Strength | Soft | Cold-Worked | Soft | Hardened and Tempered | Hardened and Tempered | |

Stainless Steel Properties

Extract from DIN 267 Part 11 – Chemical Composition of austenitic chromium-nickels steels in % by weight

| Austenitic Grade | Material No. to AISI | C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|---|

| A1 | 303 | 0.12 | 1.0 | 2.0 | 0.20 | 0.15 to 0.35 | 17.0 to 19.0 | 0.6 | 8.0 to 10.0 |

| A2 | 304 | 0.08 | 1.0 | 2.0 | 0.05 | 0.03 | 17.0 to 20.0 | – | 8.0 to 13.0 |

| A4 | 316 | 0.08 | 1.0 | 2.0 | 0.05 | 0.03 | 16.0 to 18.5 | 2.0 to 3.0 | 10.0 to 14.4 |

|

Mechanical Properties-Austenitic Grades

Bolts, Screws and Studs

| Grade | Property Class | Tensile Strength Rm MPa (N/mm2) minimum | Yield Stress Rp 0.2 Mpa (N/mm2) minimum | Elongation AL Minimum | Diameter Range |

|---|---|---|---|---|---|

| A2 and A4 | 70 | 700 | 450 | 0.4d | =<M20 |

| 80 | 800 | 600 | 0.3d | =<M20 |

Comparison: US and ISO (DIN) Stainless Steels

Tensile Load

| A2 and A4 as compared to 304 and 316 | Percent difference from US – Stainless Steel |

|---|---|

| up to M20 | 44% higher |

| M22 and over | 6% lower |

Selection of Diameters - Tightening Torques, Loads

Guideline values for screws in steel groups A2-70 and A4-70 with standard metric threads to DIN 13

| Diameter | Load 1)Force at 0.2% yield point N | Initial Stressing ForceN | Tightening Torque Nm | Force in service N | ||

|---|---|---|---|---|---|---|

| Axial Static | Axial Dynamic | Radial Static or Dynamic | ||||

| M3 | 2250 | 1420 | 0.9 | 610 | 360 | 120 |

| M4 | 3960 | 2490 | 2.2 | 1070 | 640 | 210 |

| M5 | 6390 | 4030 | 4.3 | 1730 | 1040 | 350 |

| M6 | 9040 | 5700 | 7.3 | 2440 | 1470 | 490 |

| M8 | 16470 | 10380 | 17.7 | 4450 | 2670 | 890 |

| M10 | 26100 | 16440 | 35.5 | 7050 | 4230 | 1410 |

| M12 | 37930 | 23900 | 61.3 | 10240 | 6150 | 2050 |

| M16 | 70650 | 44510 | 147.1 | 19080 | 11450 | 3820 |

| M20 | 110250 | 69460 | 285.1 | 29770 | 17860 | 5950 |

| 1)The values correspond to 100% of the 0.2% Notes on application:

**The table above is only intended as an aid for quick comparison** |

Comparative International Stainless Steel Grades

| British | French | German | Italian | Japanese | Swedish | USA |

|---|---|---|---|---|---|---|

| 304S21 | Z12CN17.08 | 1.4310 | X12CrNi 17 07 | SUS301 | 14 23 31 | 301 |

| 304S31 | SUS302 | 14 23 32 | 302 | |||

| 304S15304S16 | Z8CN18.09 | 1.4301 | X5CrNi 18 10 | SUS301 | 14 23 33 | 304 |

| 304S11 | Z2CN18.10 | 1.4306 | X2CrNi 18 11 | SUS304L | 14 23 52 | 304L |

| 305S19 | Z8CN18.12 | X8CrNi 18 12 | SUS305 | 305 | ||

| 309S24 | Z15CN24.13 | X16CrNi 23 14 | SUS309 | 309 | ||

| 310S24 | Z12CN25.20 | 1.4845 | Z22CrNi 25 20 | SUS310S | 14 23 61 | 310 |

| 315S16 | 14 23 40 | |||||

| 316S31316S33 | Z6CND17.11 | 1.44011.4436 | X8CrNiMo 17 13 | SUS316 | 14 23 4314 23 47 | 316 |

| 316S11316S13 | Z2CND17.12 | 1.44041.4435 | X2CrNiMo 17 12 | SUS316L | 14 23 5314 23 48 | 316L |

| 317S12 | Z2CND19.15 | 1.4435 | X2CrNiMo 18 16 | SUS317L | 14 23 67 | 317L |

| 317S16 | 1.4436 | SUS317 | 14 23 66 | 317 | ||

| 320S31320S33 | Z8CND17.12 | 1.45711.4573 | 14 23 50 | |||

| 321S31 | Z6CNT18.12 | 1.4541 | X6CrNiTi 18 11 | SUS321 | 14 23 37 | 321 |

| 347S31 | Z6CNNb18.11 | 1.4558 | X6CrNiNb 18 11X8CrNiNb 18 11 | SUS347 | 14 23 38 | 347 |

| 403S17 | Z6C13 | 1.4000 | X6Cr13 | SUS403 | 14 23 01 | 403 |

| 405S17 | Z6CA13 | 1.4002 | Z6CrA1 13 | SUS405 | 405 | |

| 409S19 | 1.4512 | 409 | ||||

| 430S17 | Z8C17 | 1.4016 | X8Cr 17 | SUS430 | 14 23 20 | 430 |

| 434S17 | Z8CD17.01 | 1.4113 | X8CrMo 17 | SUS434 | 14 23 25 | 434 |

| 410S21 | Z12C13 | 1.40061.4024 | X12Cr 13 | SUS410 | 13 23 02 | 410 |

| 410S45 | Z30C13 | X30Cr 13 | SUS420JS | 14 23 04 | 420 |

*All information is strictly informative

Fasteners Thread Identification Chart (American Standard) Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Thread Identification Chart (American Standard) / Fasteners Thread Identification Chart (American Standard)

| Basic Major Diameter | ||||||

|---|---|---|---|---|---|---|

| Nom Dia. | Threads Per Inch | |||||

| Inch | mm | UNC | UNF | UNEF | UNM | |

| .0118 | 0.30 | |||||

| .0118 | 0.30 | 0.30 | 318 | |||

| .0138 | 0.35 | 0.35 | 282 | |||

| .0146 | 0.37 | |||||

| .0157 | 0.40 | 0.40 | 254 | |||

| .0165 | 0.42 | |||||

| .0177 | 0.45 | 0.45 | 254 | |||

| .0189 | 0.48 | |||||

| .0197 | 0.50 | 0.50 | 203 | |||

| .0209 | 0.53 | 160 | ||||

| .0213 | 0.54 | |||||

| .0217 | 0.55 | 0.55 | 203 | |||

| .0236 | 0.60 | 0.60 | 169 | |||

| .0244 | 0.62 | |||||

| .0276 | 0.70 | 0.70 | 145 | |||

| .0311 | 0.79 | |||||

| .0315 | 0.80 | 0.80 | 127 | |||

| .0340 | 0.86 | 120 | ||||

| .0354 | 0.90 | 0.90 | 113 | |||

| .0394 | 1.00 | 1.00 | 102 | |||

| .0433 | 1.10 | 1.10 | 102 | |||

| .0470 | 1.19 | 90 | 96 | |||

| .0472 | 1.20 | 1.20 | ||||

| .0512 | 1.30 | |||||

| .0551 | 1.40 | 1.40 | 85 | |||

| .0591 | 1.50 | |||||

| .0600 | 1.52 | 80 | ||||

| .0629 | 1.60 | |||||

| .0669 | 1.70 | |||||

| .0709 | 1.80 | |||||

| .0730 | 1.85 | #1 | 64 | 72 | ||

| .0748 | 1.90 | |||||

| .0787 | 2.00 | |||||

| .0860 | 2.18 | #2 | 56 | 64 | ||

| .0866 | 2.20 | |||||

| .0906 | 2.30 | |||||

| .0984 | 2.50 | |||||

| .0990 | 2.51 | #3 | 48 | 56 | ||

| .1024 | 2.60 | |||||

| .1102 | 2.80 | |||||

| .1120 | 2.84 | #4 | 40 | 48 | ||

| .1181 | 3.00 | |||||

| .1250 | 3.18 | #5 | 40 | 44 | ||

| .1260 | 3.20 | |||||

| .1380 | 3.50 | #6 | 32 | 40 | ||

| .1417 | 3.60 | |||||

| .1575 | 4.00 | |||||

| .1614 | 4.10 | |||||

| .1640 | 4.17 | #8 | 32 | 36 | ||

| .1772 | 4.50 | |||||

| .1850 | 4.70 | |||||

| .1875 | 4.76 | |||||

| .1900 | 4.83 | #10 | 24 | 32 | ||

| .1969 | 5.00 | |||||

| .2087 | 5.30 | |||||

| .2160 | 5.49 | #12 | 24 | 28 | 32 | |

| .2165 | 5.50 | |||||

| .2188 | 5.56 | |||||

| .2362 | 6.00 | |||||

| .2500 | 6.35 | 1/4 | 20 | 28 | 32 | |

| .2756 | 7.00 | |||||

| .2812 | 7.14 | |||||

| .3125 | 7.94 | 5/16 | 18 | 24 | 32 | |

| .3125 | 7.94 | 1/16 | 27 | |||

| .3150 | 8.00 | |||||

| .3543 | 9.00 | |||||

| .3750 | 9.53 | 3/8 | 16 | 24 | 32 | |

| .3830 | 9.73 | |||||

| .3937 | 10.00 | |||||

| .4050 | 10.29 | 1/8 | 27 | |||

| .4331 | 11.00 | |||||

| .4375 | 11.11 | 7/16 | 14 | 20 | 28 | |

| .4724 | 12.00 | |||||

| .5000 | 12.70 | 1/2 | 13 | 20 | 28 | |

| .5180 | 13.16 | |||||

| .5400 | 13.72 | 1/4 | 18 | |||

| .5512 | 14.00 | |||||

| .5625 | 14.29 | 9/16 | 12 | 18 | 24 | |

| .6250 | 15.88 | 5/8 | 11 | 18 | 24 | |

| .6299 | 16.00 | |||||

| .6560 | 16.66 | |||||

| .6750 | 17.15 | 3/8 | 18 | |||

| .6875 | 17.46 | 11/16 | 24 | |||

| .7087 | 18.00 | |||||

| .7500 | 19.05 | 3/4 | 10 | 16 | 20 | |

| .7874 | 20.00 | |||||

| .8125 | 20.64 | 13/16 | 20 | |||

| .8250 | 20.96 | |||||

| .8400 | 21.34 | 1/2 | 14 | |||

| .8661 | 22.00 | |||||

| .8750 | 22.23 | 7/8 | 9 | 14 | 20 | |

| .9020 | 22.91 | |||||

| .9375 | 23.81 | 15/16 | 20 | |||

| .9449 | 24.00 | |||||

| 1.0000 | 25.40 | 1 | 8 | 14 | 20 | |

| 1.0236 | 26.00 | |||||

| 1.0410 | 26.44 | |||||

| 1.0500 | 26.67 | 3/4 | 14 | |||

| 1.0625 | 26.99 | 1 1/16 | 18 | |||

| 1.0630 | 27.00 | |||||

| 1.1250 | 28.58 | 1 1/8 | 7 | 12 | 18 | |

| 1.1811 | 30.00 | |||||

| 1.1875 | 30.16 | 1 3/16 | 18 | |||

| 1.1890 | 30.20 | |||||

| 1.2500 | 31.75 | 1 1/4 | 7 | 12 | 18 | |

| 1.2598 | 32.00 | |||||

| 1.2992 | 33.00 | |||||

| 1.3090 | 33.25 | |||||

| 1.3125 | 33.34 | 1 5/16 | 18 | |||

| 1.3150 | 33.40 | 1 | 11 1/2 | |||

| 1.3750 | 34.93 | 1 3/8 | 6 | 12 | 18 | |

| 1.3780 | 35.00 | |||||

| 1.4173 | 36.00 | |||||

| 1.4375 | 36.51 | 1 7/16 | 18 | |||

| 1.4920 | 37.90 | |||||

| 1.4961 | 38.00 | |||||

| 1.5000 | 38.10 | 1 1/2 | 6 | 12 | 18 | |

| 1.5354 | 39.00 | |||||

| 1.5625 | 39.69 | 1 9/16 | 18 | |||

| 1.5748 | 40.00 | |||||

| 1.6250 | 41.28 | 1 5/8 | 18 | |||

| 1.6500 | 41.91 | |||||

| 1.6535 | 42.00 | |||||

| 1.6600 | 42.16 | 1 1/4 | 11 1/2 | |||

| 1.6875 | 42.86 | 1 11/16 | 18 | |||

| 1.7450 | 44.32 | |||||

| UNC-Unified National Course UNF-Unified National FineUNEF-Unified National Extra Fine UNM-Unified National Miniature |

NPT-National Pipe Tapered

*All information is strictly informative

Fasteners Thread Identification Chart (Metric – Coarse/Fine) Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Thread Identification Chart (Metric – Coarse/Fine) / Fasteners Thread Identification Chart (Metric – Coarse/Fine)

Thread Identification Chart (Metric – Coarse/Fine)

| A screw thread in conformity with this International Standard is designated by the letter M followed by the values of the nominal diameter and of the pitch expressed in millimetres separated by the sign x. |

| Example : M 8 x 1.0 (Fine pitch 1.0) |

| The absence of the indication of pitch means that the coarse pitch is specified. |

| Example : M 8 (Coarse pitch 1.25) |

| The words “coarse” and “fine” are given in order to conform to usage. No concept of quality however, is associated with these words. “Coarse” pitches are the largest metric pitches used. For the diameter selected, choose one of the pitches shown on the corresponding line. |

| Basic Major Diameter | Nominal Diameter (mm) | STD | Pitch in mm | |||

|---|---|---|---|---|---|---|

| Inch | mm | Coarse | Fine | M Taper | ||

| .0118 | 0.30 | 0.30 | X | 0.075 | ||

| .0118 | 0.30 | 0.30 | * | 0.080 | ||

| .0138 | 0.35 | 0.35 | ** | 0.090 | ||

| .0146 | 0.37 | |||||

| .0157 | 0.40 | 0.40 | *X | 0.100 | ||

| .0165 | 0.42 | |||||

| .0177 | 0.45 | 0.45 | ** | 0.100 | ||

| .0189 | 0.48 | |||||

| .0197 | 0.50 | 0.50 | *X | 0.125 | ||

| .0209 | 0.53 | |||||

| .0213 | 0.54 | |||||

| .0217 | 0.55 | 0.55 | ** | 0.125 | ||

| .0236 | 0.60 | 0.60 | *X | 0.150 | ||

| .0244 | 0.62 | |||||

| .0276 | 0.70 | 0.70 | 0.175 | |||

| .0311 | 0.79 | |||||

| .0315 | 0.80 | 0.80 | *X | 0.200 | ||

| .0340 | 0.86 | |||||

| .0354 | 0.90 | 0.90 | **X | 0.225 | ||

| .0394 | 1.00 | 1.00 | *X | 0.250 | 0.2 | |

| .0433 | 1.10 | 1.10 | ** | 0.250 | 0.2 | |

| .0470 | 1.19 | |||||

| .0472 | 1.20 | 1.20 | *X | 0.250 | 0.2 | |

| .0512 | 1.30 | |||||

| .0551 | 1.40 | 1.40 | **X | 0.300 | 0.2 | |

| .0591 | 1.50 | 1.50 | 0.300 | |||

| .0600 | 1.52 | |||||

| .0629 | 1.60 | 1.60 | * | 0.350 | 0.2 | |

| .0669 | 1.70 | 1.70 | X | 0.350 | 0.2,0.25 | |

| .0709 | 1.80 | 1.80 | ** | 0.350 | 0.2 | |

| .0730 | 1.85 | |||||

| .0748 | 1.90 | |||||

| .0787 | 2.00 | 2.00 | *X | 0.400 | 0.25,0.35 | |

| .0860 | 2.18 | |||||

| .0866 | 2.20 | 2.20 | ** | 0.450 | 0.25 | |

| .0906 | 2.30 | 2.30 | X | 0.400 | 0.25,0.35 | |

| .0984 | 2.50 | 2.50 | * | 0.45 | 0.35 | |

| .0990 | 2.51 | |||||

| .1024 | 2.60 | 2.60 | X | 0.45 | 0.25,0.35 | |

| .1102 | 2.80 | |||||

| .1120 | 2.84 | |||||

| .1181 | 3.00 | 3.00 | *X | 0.50 | 0.35 | |

| .1250 | 3.18 | |||||

| .1260 | 3.20 | |||||

| .1380 | 3.50 | 3.50 | **X | 0.60 | 0.35,0.5 | |

| .1417 | 3.60 | |||||

| .1575 | 4.00 | 4.00 | *X | 0.70 | 0.5,0.75 | |

| .1614 | 4.10 | |||||

| .1640 | 4.17 | |||||

| .1772 | 4.50 | 4.50 | ** | 0.75 | 0.5 | |

| .1850 | 4.70 | |||||

| .1875 | 4.76 | |||||

| .1900 | 4.83 | |||||

| .1969 | 5.00 | 5.00 | *X | 0.80 | 0.5, 0.75, 0.90 | |

| .2087 | 5.30 | |||||

| .2160 | 5.49 | |||||

| .2165 | 5.50 | 5.50 | *** | 0.90 | 0.5 | |

| .2188 | 5.56 | |||||

| .2362 | 6.00 | 6.00 | *X | 1.00 | 0.5, 0.75 | |

| .2500 | 6.35 | |||||

| .2756 | 7.00 | 7.00 | ***X | 1.00 | 0.5, 0.75 | |

| .2812 | 7.14 | |||||

| .3125 | 7.94 | |||||

| .3125 | 7.94 | |||||

| .3150 | 8.00 | 8.00 | *X | 1.25 | 0.5, 0.75, 1 | |

| .3543 | 9.00 | 9.00 | ***X | 1.25 | 0.75, 1 | |

| .3750 | 9.53 | |||||

| .3830 | 9.73 | 1 | ||||

| .3937 | 10.00 | 10.00 | *X | 1.5 | 0.75, 1, 1.25 | |

| .4050 | 10.29 | |||||

| .4331 | 11.00 | 11.00 | ***X | 1.5 | 0.75, 1, 1.25 | |

| .4375 | 11.11 | |||||

| .4724 | 12.00 | 12.00 | *X | 1.75 | 1, 1.25, 1.5 | 1.5 |

| .5000 | 12.70 | |||||

| .5180 | 13.16 | |||||

| .5400 | 13.72 | |||||

| .5512 | 14.00 | 14.00 | **X | 2.00 | 1, 1.25, 1.5 | |

| .5625 | 14.29 | |||||

| .6250 | 15.88 | |||||

| .6299 | 16.00 | 16.00 | *X | 2.00 | 1, 1.5 | 1.5 |

| .6560 | 16.66 | |||||

| .6750 | 17.15 | |||||

| .6875 | 17.46 | |||||

| .7087 | 18.00 | 18.00 | **X | 2.5 | 1, 1.5, 2 | 1.5 |

| .7500 | 19.05 | |||||

| .7874 | 20.00 | 20 | *X | 2.5 | 1, 1.5, 2 | 1.5 |

| .8125 | 20.64 | |||||

| .8250 | 20.96 | |||||

| .8400 | 21.34 | |||||

| .8661 | 22.00 | 22 | **X | 2.5 | 1, 1.5, 2 | 1.5 |

| .8750 | 22.23 | |||||

| .9020 | 22.91 | |||||

| .9375 | 23.81 | |||||

| .9449 | 24.00 | 24 | *X | 3 | 1, 1.5, 2 | |

| 1.0000 | 25.40 | |||||

| 1.0236 | 26.00 | 26 | ***X | 1.5 | 1.5 | |

| 1.041011 | 26.44 | |||||

| 1.0500 | 26.67 | |||||

| 1.0625 | 26.99 | |||||

| 1.0630 | 27.00 | 27 | **X | 3 | 1, 1.5, 2 | |

| 1.1250 | 28.58 | |||||

| 1.1811 | 30.00 | 30 | *X | 3.5 | 1, 1.5, 2, 3 | |

| 1.1875 | 30.16 | |||||

| 1.1890 | 30.20 | |||||

| 1.2500 | 31.75 | |||||

| 1.2598 | 32.00 | 32 | ***X | 1.5, 2 | ||

| 1.2992 | 33.00 | 33 | **X | 3.5 | 1.5, 2, 3 | |

| 1.3090 | 33.25 | |||||

| 1.3125 | 33.34 | |||||

| 1.3150 | 33.40 | |||||

| 1.3750 | 34.93 | |||||

| 1.3780 | 35.00 | 35 | ***X | 1.5 | ||

| 1.4173 | 36.00 | 36 | *X | 4 | 1.5, 2, 3 | |

| 1.4375 | 36.51 | |||||

| 1.4920 | 37.90 | 1.5 | ||||

| 1.4961 | 38.00 | 38 | ***X | |||

| 1.5000 | 38.10 | |||||

| 1.5354 | 39.00 | 39 | **X | 4 | 1.5, 2, 3 | |

| 1.5625 | 39.69 | |||||

| 1.5748 | 40.00 | 40 | ***X | 1.5, 2, 3 | ||

| 1.6250 | 41.28 | |||||

| 1.6500 | 41.91 | |||||

| 1.6535 | 42.00 | 42 | *X | 4.5 | 1.5, 2, 3, 4 | |

| 1.6600 | 42.16 | |||||

| 1.6875 | 42.86 | |||||

| 1.7450 | 44.32 | |||||

** ISO Standard-2nd Choice

*** ISO Standard-3rd Choice

X DIN (German Standard)

*All information is strictly informative

Fasteners Torque Information Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Torque Information / Fasteners Torque Information

Two major points have to be accounted for when installing a fastener.

- 1. Inaccuracy of torque wrench tightening method can range anywhere from ±17 to ±23%

- 2. The friction coefficient changes when using lubrication on the thread.

1. Inaccuracy of tightening method

A torque wrench has a “scatter” (tolerance) of ±17% to ±23%. We must account for this in order not to over-tighten the fastener.

| Example: |

Torque should be set to 1,854 Nm (mean torque) on the torque wrench |

The accuracy of the tightening method needs to be accounted for, in order to not over-tighten the fastener.

2. Friction coefficient

The surface condition of a fastener may change the torque that can be applied and needs to be accounted for.

| Friction coefficients for standard finish fasteners | |||

| Surface Condition | Lubrication Condition | ||

|---|---|---|---|

| Screw | Nut | Oiled | MoS2-Paste |

| – no treatment – phosphate | – no treatment | 0.12-0.18 | 0.05-0.10 |

| – electroplated appx. 8 μm | – electroplated appx. 5 μm | 0.12-0.18 | |

| – dacromet-coated 6-8 μm | – dacromet-coated 6-8 μm | 0.10-0.14 | |

| Example: | A M30-12.9 fastener using MoS2 paste.

Torque should be set to 1,602 Nm (mean torque) on the torque wrench |

The accuracy of the tightening method, as well as the change in friction, needs to be accounted for in order not to over-tighten the fastener.

General Torque Figures

A torque value will be influenced by the fastening methods and tools used. The only way to determine an exact torque value is by actual application. The following figures are general guidelines only.

Figures in ft. lbs.

| Thread Diameter | Property Class | ||

|---|---|---|---|

| 8.8 | 10.9 | 12.9 | |

| M3 | 0.80 | 1.1 | 1.3 |

| M4 | 1.8 | 2.6 | 3.1 |

| M5 | 3.6 | 5.1 | 6.2 |

| M6 | 7 | 10 | 12 |

| M8 | 17 | 25 | 29 |

| M10 | 33 | 48 | 58 |

| M12 | 60 | 85 | 102 |

| M14 | 97 | 137 | 165 |

| M16 | 150 | 208 | 250 |

| M18 | 201 | 287 | 342 |

| M20 | 282 | 398 | 479 |

| M22 | 390 | 552 | 664 |

| M24 | 499 | 750 | 843 |

| M27 | 746 | 1051 | 1266 |

| M30 | 982 | 1383 | 1657 |

| M33 | 1331 | 1875 | 2250 |

| M36 | 1717 | 2407 | 2895 |

| M39 | 2220 | 3120 | 3750 |

| M42 | 2737 | 3840 | 4638 |

| M45 | 3390 | 4762 | 5722 |

| M48 | 4095 | 5775 | 6825 |

| M52 | 5250 | 7387 | 9000 |

| M56 | 6547 | 9225 | 11280 |

| M60 | 8175 | 11475 | 13800 |

| M64 | 9900 | 13950 | 17175 |

| M68 | 12000 | 16950 | 20100 |

| M72 | 14250 | 20100 | 24000 |

| M76 | 16800 | 23625 | 28350 |

| M80 | 19725 | 27600 | 33375 |

| M85 | 24000 | 33225 | 40125 |

| M90 | 28350 | 38925 | 47700 |

| M95 | 33450 | 46875 | 56250 |

| M100 | 39000 | 54750 | 66000 |

Torque – Metric Fasteners

| Diameter | Recommended Seating Torque (NM) | Proof Torque min. (NM) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ISO 4762DIN 912 | DIN 7984 | ISO 10642DIN 7991 | ISO 7380 | ISO 7379 | ISO 4014/ 4017DIN 931 / DIN 933 | ISO 4162 | ISO4026 / 4027 4028 / 4029 | ||||||

| Socket CapScrews | Low HeadSocket Cap Screws | Flat HeadCountersunk Socket Cap Screws | Button HeadSocket Cap Screws | SocketShoulder Screws | Hexagon HeadCap Screws | Hexagon FlangeScrews | Socket SetScrews | ||||||

| 10.9 | 12.9 | 10.9 | 10.9 | 12.9 | 10.9 | 12.9 | 12.9 | 10.9 | 12.9 | 10.9 | 12.9 | 45H | |

| M1.6 | 0.25 | 0.30 | |||||||||||

| M2 | 0.50 | 0.63 | |||||||||||

| M2.5 | 1.03 | 1.27 | |||||||||||

| M3 | 1.83 | 2.20 | 1.15 | 1.15 | 1.35 | 1.15 | 1.35 | 0.90 | |||||

| M4 | 4.27 | 4.83 | 2.70 | 2.70 | 3.10 | 2.70 | 3.10 | 2.50 | |||||

| M5 | 8.64 | 10.0 | 5.40 | 5.40 | 6.10 | 5.40 | 6.10 | 8.64 | 10.0 | 8.64 | 10.0 | 5.00 | |

| M6 | 14.7 | 16.8 | 9.15 | 9.15 | 10.5 | 9.15 | 10.5 | 5.6 | 14.7 | 16.8 | 14.7 | 16.8 | 8.50 |

| M6.5 | 5.6 | ||||||||||||

| M8 | 35.6 | 41.0 | 22.0 | 22.0 | 26.0 | 22.0 | 26.0 | 9.6 | 35.6 | 41.0 | 35.6 | 41.0 | 20.0 |

| M10 | 70.6 | 81.0 | 44.0 | 44.0 | 52.0 | 44.0 | 52.0 | 25 | 70.6 | 81.0 | 70.6 | 81.0 | 40.0 |

| M12 | 123 | 142 | 77.0 | 77.0 | 90.0 | 77.0 | 90.0 | 51 | 123 | 142 | 123 | 142 | 65.0 |

| M13 | 51 | ||||||||||||

| M14 | 195 | 226 | 122 | 122 | 143 australianpharmall.com | 195 | 226 | 195 | 226 | 65.0 | |||

| M16 | 305 | 350 | 190 | 190 | 225 | 190 | 225 | 92 | 305 | 350 | 305 | 350 | 160 |

| M18 | 420 | 485 | 262 | 420 | 485 | 310 | |||||||

| M20 | 596 | 685 | 371 | 370 | 440 | 245 | 596 | 685 | 310 | ||||

| M22 | 811 | 930 | 811 | 930 | |||||||||

| M24 | 1031 | 1180 | 1031 | 1180 | |||||||||

| M25 | 485 | ||||||||||||

| M27 | 1508 | 1730 | 1508 | 1730 | |||||||||

| M30 | 2048 | 2380 | 2048 | 2380 | |||||||||

| M33 | 2787 | 3262 | |||||||||||

| M36 | 3580 | 4190 | |||||||||||

| M39 | 4633 | 5420 | |||||||||||

Torque – Imperial Fasteners

| Diameter | Recommended Seating Torque (in-lb) | Proof Torque min. (in-lb) | ||||||

|---|---|---|---|---|---|---|---|---|

| ASME B18.3 | ASME B18.2.1 | IFI-111 | ASME B18.3 | |||||

| Socket CapScrews | Low HeadSocket Cap Screws | Flat HeadCountersunk Socket Cap Screws | Button HeadSocket Cap Screws | Socket Shoulder Screws | Hexagon HeadCap Screws SAE J429 Grade 8 | Hexagon FlangeScrews SAE J429 Grade 8 | Socket SetScrews | |

| #0 | 2.26 | 1.42 | 1.42 | 1.1 | ||||

| #1 | 4.01 | 2.52 | 2.52 | 2.1 | ||||

| #2 | 6.65 | 4.18 | 4.18 | 2.1 | ||||

| #3 | 10.1 | 6.33 | 6.33 | 6.0 | ||||

| #4 | 14.1 | 8.88 | 8.88 | 8.88 | 6.0 | |||

| #5 | 20.8 | 13.1 | 13.1 | 13.1 | 11 | |||

| #6 | 26.2 | 16.5 | 16.5 | 16.5 | 11 | |||

| #8 | 48.0 | 30.1 | 30.1 | 30.1 | 23 | |||

| #10 | 69.5 | 43.7 | 43.7 | 43.7 | 40 | |||

| 1/4 | 166 | 104 | 104 | 104 | 35 | 134 | 134 | 94 |

| 5/16 | 342 | 215 | 215 | 215 | 90 | 277 | 277 | 183 |

| 3/8 | 608 | 382 | 382 | 382 | 200 | 491 | 491 | 317 |

| 7/16 | 973 | 611 | 611 | 785 | 785 | 502 | ||

| 1/2 | 1484 | 931 | 931 | 931 | 363 | 1202 | 1202 | 750 |

| 9/16 | 1732 | 1732 | ||||||

| 5/8 | 2792 | 1722 | 1722 | 1722 | 922 | 2386 | 2386 | 1460 |

| 3/4 | 4952 | 3054 | 1864 | 4225 | 4225 | 2520 | ||

| 7/8 | 7991 | 4928 | 6823 | 5750 | ||||

| 1 | 11979 | 7388 | 3443 | 10226 | 8000 | |||

| 1-1/8 | 16968 | 10464 | 14485 | |||||

| 1-1/4 | 23944 | 14766 | 5637 | 20442 | ||||

| 1-3/8 | 31394 | 19360 | 26806 | |||||

| 1-1/2 | 41611 | 25692 | 12002 | 35573 | ||||

*All information is strictly informative

ISO Metric (Coarse) Threads Dimensions, Weight Chart & Material Specification & TolerancesISO Metric (Coarse) Threads / ISO Metric (Coarse) ThreadsISO Metric (Coarse) Threads Dimensions, Weight Chart & Material Specification & Tolerances

ISO Metric (Coarse) Threads ISO 898/I-1988

| Nominal Diameter Of Thread d(mm) | Pitch P(mm) | Nomincal Stress Area As (mm2) | Property Class | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3.6 | 4.6 | 4.8 | 5.6 | 5.8 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 | |||

| Proof Load (As . Ap),N | ||||||||||||

| 3 | 0.50 | 5.03 | 910 | 1130 | 1560 | 1410 | 1910 | 2210 | 2920 | 3270 | 4180 | 4880 |

| 3.5 | 0.60 | 6.78 | 1220 | 1530 | 2100 | 1900 | 2580 | 2980 | 3940 | 4410 | 5630 | 6580 |

| 4 | 0.70 | 8.78 | 1580 | 1980 | 2770 | 2460 | 3340 | 3860 | 5100 | 5710 | 7290 | 8520 |

| 5 | 0.80 | 14.20 | 2560 | 3200 | 4400 | 3980 | 5400 | 6250 | 8230 | 9230 | 11800 | 13800 |

| 6 | 1.00 | 20.10 | 3620 | 4520 | 6230 | 5630 | 7640 | 8840 | 11600 | 13100 | 16700 | 19500 |

| 7 | 1.00 | 28.90 | 5200 | 6500 | 8920 | 8090 | 11000 | 12700 | 16800 | 18800 | 24000 | 28000 |

| 8 | 1.25 | 36.60 | 6590 | 8240 | 11400 | 10200 | 13900 | 16100 | 21200 | 23800 | 30400 | 35500 |

| 10 | 1.50 | 58.00 | 10400 | 13000 | 18000 | 16200 | 22000 | 25500 | 33700 | 37700 | 48100 | 56300 |

| 12 | 1.75 | 84.30 | 15200 | 19000 | 26100 | 23600 | 32000 | 37100 | 489001) | 54800 | 70000 | 81800 |

| 14 | 2.00 | 115 | 20700 | 25900 | 35600 | 32200 | 43700 | 50600 | 667001) | 74800 | 95500 | 112000 |

| 16 | 2.00 | 157 | 28300 | 35300 | 48700 | 44000 | 59700 | 69100 | 910001) | 102000 | 130000 | 152000 |

| 18 | 2.50 | 192 | 34600 | 43200 | 59500 | 53800 | 73000 | 84500 | 11500 | 159000 | 186000 | |

| 20 | 2.50 | 245 | 44100 | 55100 | 76000 | 68600 | 93100 | 108000 | 147000 | 203000 | 238000 | |

| 22 | 2.50 | 303 | 54500 | 68200 | 93900 | 84800 | 115000 | 133000 | 182000 | 252000 | 294000 | |

| 24 | 3.00 | 353 | 63500 | 79400 | 109000 | 98800 | 134000 | 155000 | 212000 | 293000 | 342000 | |

| 27 | 3.00 | 459 | 82600 | 103000 | 142000 | 128000 | 174000 | 202000 | 275000 | 381000 | 445000 | |

| 30 | 3.50 | 561 | 101000 | 126000 | 174000 | 157000 | 213000 | 247000 | 337000 | 466000 | 544000 | |

| 33 | 3.50 | 694 | 125000 | 156000 | 215000 | 194000 | 264000 | 305000 | 416000 | 570000 | 673000 | |

| 36 | 4.00 | 817 | 147000 | 184000 | 253000 | 229000 | 310000 | 359000 | 490000 | 678000 | 792000 | |

| 39 | 4.00 | 976 | 176000 | 220000 | 303000 | 273000 | 371000 | 429000 | 586000 | 810000 | 947000 | |

1)For structural steel screws 50700,68800 and 94500 N

Proof Loads For Screws

ISO Metric (Fine) Threads ISO 898/I-1988

| Nominal Diameter Of Thread d(mm) | Pitch P(mm) | Nomincal Stress Area As (mm2) | Property Class | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3.6 | 4.6 | 4.8 | 5.6 | 5.8 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 | |||

| Proof Load (As . Ap),N | ||||||||||||

| 8 | 1.00 | 39.2 | 7060 | 8820 | 12200 | 11000 | 14900 | 17200 | 22700 | 25500 | 32500 | 38000 |

| 10 | 1.25 | 61.2 | 11000 | 13800 | 19000 | 17100 | 23300 | 26900 | 33500 | 39800 | 50800 | 59400 |

| 12 | 1.25 | 92.1 | 16600 | 20700 | 28600 | 25800 | 35000 | 40500 | 53400 | 59900 | 76300 | 89300 |

| 14 | 1.50 | 125 | 22500 | 28100 | 38800 | 35000 | 47500 | 55000 | 72500 | 81200 | 104000 | 121000 |

| 16 | 1.50 | 167 | 30100 | 27600 | 51800 | 46800 | 63500 | 73500 | 96900 | 109000 | 139000 | 162000 |

| 18 | 1.50 | 216 | 38900 | 48600 | 67000 | 60500 | 82100 | 95000 | 130000 | 179000 | 210000 | |

| 20 | 1.50 | 272 | 49000 | 61200 | 84300 | 76200 | 103000 | 120000 | 163000 | 226000 | 264000 | |

| 22 | 1.50 | 333 | 59900 | 74900 | 103000 | 93200 | 126000 | 146000 | 200000 | 276000 | 323000 | |

| 24 | 2.00 | 384 | 69100 | 86400 | 119000 | 108000 | 146000 | 169000 | 230000 | 319000 | 372000 | |

| 27 | 2.00 | 496 | 89300 | 112000 | 154000 | 139000 | 188000 | 218000 | 298000 | 412000 | 481000 | |

| 30 | 2.00 | 621 | 112000 | 140000 | 192000 | 171000 | 236000 | 273000 | 373000 | 515000 | 602000 | |

| 33 | 2.00 | 761 | 137000 | 171000 | 236000 | 213000 | 289000 | 335000 | 457000 | 632000 | 738000 | |

| 36 | 3.00 | 865 | 156000 | 195000 | 268000 | 242000 | 329000 | 381000 | 519000 | 718000 | 838000 | |

| 39 | 3.00 | 1030 | 185000 | 232000 | 319000 | 288000 | 391000 | 453000 | 618000 | 855000 | 999000 | |

Proof Loads For Nuts (Coarse Thread)

According to DIN 934 and DIN 985 (Ref. DIN 267/4)

| Thread Size | Pitch P(mm) | Nominal Stress Area of Test Mandrel As mm2 | Property Class | |||||

|---|---|---|---|---|---|---|---|---|

| 4 | 5 | 6 | 8 | 10 | 12 | |||

| Proof Load (As * Sp), in N | ||||||||

| M3 | 0.50 | 5.03 | 2500 | 3000 | 4000 | 5000 | 6000 | |

| M3.5 | 0.60 | 6.78 | 3400 | 4050 | 5400 | 6800 | 8150 | |

| M4 | 0.70 | 8.78 | 4400 | 5250 | 7000 | 8750 | 10500 | |

| M5 | 0.80 | 14.2 | 7100 | 8500 | 11400 | 11400 | 17000 | |

| M6 | 1.00 | 20.1 | 10000 | 12000 | 16000 | 20000 | 24000 | |

| M7 | 1.00 | 28.9 | 14500 | 17300 | 23000 | 29000 | 34700 | |

| M8 | 1.25 | 36.6 | 18300 | 22000 | 29000 | 36500 | 43000 | |

| M10 | 1.50 | 58.0 | 29000 | 35000 | 46000 | 58000 | 69500 | |

| M12 | 1.75 | 84.5 | 42100 | 50500 | 67000 | 84000 | 100000 | |

| M14 | 2.00 | 115 | 57500 | 69000 | 92000 | 115000 | 138000 | |

| M16 | 2.00 | 157 | 78500 | 94000 | 126000 | 157000 | 188000 | |

| M18 | 2.50 | 192 | 76800 | 96000 | 115000 | 154000 | 192000 | 230000 |

| M20 | 2.50 | 245 | 98000 | 122000 | 147000 | 196000 | 245000 | 294000 |

| M22 | 2.50 | 303 | 121000 | 151000 | 182000 | 242000 | 303000 | 364000 |

| M24 | 3.00 | 353 | 141000 | 176000 | 212000 | 282000 | 353000 | 423000 |

| M27 | 3.00 | 459 | 184000 | 230000 | 276000 | 367000 | 459000 | 550000 |

| M30 | 3.50 | 561 | 224000 | 280000 | 336000 | 448000 | 561000 | 673000 |

| M33 | 3.50 | 694 | 277000 | 347000 | 416000 | 555000 | 694000 | 833000 |

| M36 | 4.00 | 817 | 327000 | 408000 | 490000 | 653000 | 817000 | 980000 |

| M39 | 4.00 | 976 | 390000 | 488000 | 585000 | 780000 | 976000 | 1170000 |

| The above proof loads are also valid for nuts where the property class marking is enclosed by two vertical lines |8|Conversion Factor: 1N = 0.2248 lb. |

Proof Loads For Nuts (Fine Thread)

According to DIN 934 and DIN 985 (Ref. DIN 267/4)

| Thread Size | Pitch P(mm) | Nominal Stress Area of Test Mandrel As mm2 | Property Class | ||||

|---|---|---|---|---|---|---|---|

| 5 | 6 | 8 | 10 | 12 | |||

| Proof Load (As * Sp), in N | |||||||

| M8 | 1.00 | 39.2 | 19600 | 23500 | 31000 | 39000 | 47000 |

| M10 | 1.00 | 64.5 | 32200 | 38700 | 51500 | 64500 | 77500 |

| M10 | 1.25 | 61.2 | 30600 | 37000 | 49000 | 61000 | 73500 |

| M12 | 1.25 | 92.1 | 46000 | 55000 | 74000 | 92000 | 110000 |

| M12 | 1.50 | 88.1 | 44000 | 53000 | 70000 | 88000 | 106000 |

| M14 | 1.50 | 125 | 62200 | 75000 | 100000 | 125000 | 150000 |

| M16 | 1.50 | 167 | 83500 | 100000 | 134000 | 167000 | 200000 |

| M18 | 1.50 | 216 | 108000 | 129000 | 173000 | 216000 | 259000 |

| M18 | 2.00 | 204 | 102000 | 122000 | 163000 | 204000 | 245000 |

| M20 | 1.50 | 272 | 136000 | 163000 | 218000 | 272000 | 326000 |

| M20 | 2.00 | 258 | 129000 | 155000 | 206000 | 258000 | 310000 |

| M22 | 1.50 | 333 | 166000 | 200000 | 266000 | 333000 | 400000 |

| M22 | 2.00 | 318 | 159000 | 191000 | 254000 | 318000 | 382000 |

| M24 | 2.00 | 384 | 192000 | 230000 | 307000 | 384000 | 460000 |

| M27 | 2.00 | 496 | 248000 | 298000 | 397000 | 496000 | 595000 |

| M30 | 2.00 | 621 | 310000 | 373000 | 497000 | 621000 | 745000 |

| M33 | 2.00 | 761 | 380000 | 456000 | 608000 | 761000 | 914000 |

| M36 | 3.00 | 865 | 432000 | 519000 | 692000 | 865000 | 1040000 |

| M39 | 3.00 | 1030 | 501000 | 618000 | 825000 | 1030000 | 1240000 |

| The above proof loads are also valid for nuts where the property class marking is enclosed by two vertical lines |8| Conversion Factor: 1N = 0.2248 lb. |

*All information is strictly informative

Fasteners Chemical Resistance Table For Screws in A2 and A4 Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Chemical Resistance Table For Screws in A2 and A4 / Fasteners Chemical Resistance Table For Screws in A2 and A4 / Chemical Resistance Table For Screws in A2 and A4

Chemical Resistance Table For Screws in A2 and A4

| Classification of corrosion resistance:

|

| Corrosive Agent | Concentration | Temp °C | Material | |

|---|---|---|---|---|

| A2 | A4 | |||

| Effluent water (with traces of sulphuric acid) | – | up to 40° | 0 | 0 |

| Acetone CH3COCH3 | all concentrations | 20° | 0 | 0 |

| Acetyl chloride Ch3CoCl | – | boiling | 1 | 0 |

| Aluminium Al | molten 750° | 3 | 3 | |

| Aluminium Chloride L Al Cl3,6H2O | 5% | 50° | 2 | 1 |

| Formic Acid H•COOH | 10% 15% 100% | 20° 20° 20° | 0 0 0 | 0 0 0 |

| Ammonia NH3 | – | – | 0 | 0 |

| Ammonium chloride (sal ammoniac) L NH4OH | 10% 25% 50% cold and hot saturated | boiling boiling boiling 20° boiling | 0 1 2 0 2 | 0 1 1 0 1 |

| Ammonium hydroxide NH4OH | all | 20° boiling | 0 | 0 |

| Ammonium perchlorate L NH4CIO4 | 10% | 20° boiling | 0 0 | 0 0 |

| Aniline C6H7NH2 | 20° | 0 | 0 | |

| Malic acid (COOH)2CH2CH OH | up to 50% | 20° | 0 | 0 |

| Cider | – | 20° | 0 | 0 |

| Ethyl alcohol (ethanol) C2H5OH | all concentrations | 20° | 0 | 0 |

| Ethyl ether (C2H5)2•O | – | boiling | 0 | 0 |

| Atmosphere | – | – | 0 | 0 |

| Petrol | all concentrations | 20° | 0 | 0 |

| Benzoic acid C6H5CO O OH | all concentrations | 20° | 0 | 0 |

| Beer | – | 20° | 0 | 0 |

| Blood | – | – | 0 | 0 |

| Spirits | – | 20° | 0 | 0 |

| Bromine Br L | – | 20° boiling | 3 3 | 3 3 |

| Buttermilk | – | 20° | 0 | 0 |

| Butyric acid C3H7COOh | 100% | 20° | 0 | 0 |

| Chlorine Cl Gas in dry state Gas in moist state L | – – | 20° 20° 100° | 0 3 3 | 0 3 3 |

| Chloride of lime L Ca (IO)2, CaO, 2 H2O Bleaching solution | dry moist 2.5g Cl/l | 20° 20° 20° | 0 1 1 | 0 1 0 |

| Chloroform CH CL3 | water free | 20° | 0 | 0 |

| Chlorine water L =cold water saturated with water | – | 20° | 1 | 1 |

| Hydrogen chloride gas L HCI | – – – – | 20° 50° 100° 400° | 1 1 2 3 | 1 1 1 3 |

| Chromic oxide CrO3 | 10% pure 50% pure | 20° 20° | 0 1 | 0 1 |

| Ferrogallic ink L | – | 20° | 0 | 0 |

| Iron phosphate solution, bonder process | – | 98° | 0 | 0 |

| Mineral oil | – | 20° | 0 | 0 |

| Vinegar = spirit vinegar | – | 20° | 0 | 0 |

| Acetic acid CH3COOH | 10% 50% | 20° 20° | 0 0 | 0 0 |

| Glacial acetic acide boiling | 100% | 20° boiling | 0 1 | 0 1 |

| Acetic acid + hydrogen peroxide CH3COOH + H2O2 | 10 u. 50% | 20° 50° 90° | 0 0 0 | 0 0 0 |

| Dyer’s bath alkaline or neutral organically acid slightly sulphuric acid or organically acid + sulphuric acid (H2SO4 below 1%) | – – – | 20° boiling boiling20° boiling | 0 0 00 1 | 0 0 00 |

| Oleic acid C17H33COOH | 30 bar technical | 150° | 0 | 0 |

| Oleic acid + traces H2SO4 | – | hot | 2 | 1 |

| Meat | – | – | 0 | 0 |

| Hydrofluoric acid = hydrogen fluoride H2 F2 | 40% | 20° | 3 | 3 |

| Fruit juices and fruit acids | – | 20° | 0 | 0 |

| Vegetables | – | boiling | 0 | 0 |

| Tannic acid = tannin | 5% | 20° | 0 | 0 |

| Glycerin C3 H5 (OH)3 | conc. | 20° boiling | 0 0 | 0 0 |

| Pit water | acid | 20° | 0 | 0 |

| Urine L | – | 20° | 0 | 0 |

| Iodine I L | dry moist | 20° 20° | 0 1 | 0 0 |

| Coffee | – | 20° boiling | 0 0 | 0 0 |

| Potassium aluminium sulphate = alum KAL(SO4)2, 12H2O) | 10% | 20° | 0 | 0 |

| Potassium chloride L K Cl | hot saturated | 20° boiling | 0 0 | 0 0 |

| Potassium ferricyanide = red prussiate of potash K3(Fe[CN]6) | – | 0 | 0 | 0 |

| Potassium ferrocyanide = yellow prussiate or potash K4[Fe(CN)6], 3 H2O) | – | 20° boiling | 0 0 | 0 0 |

| Potassium hydroxide = caustic potash solution | 20% | 20° | 0 | 0 |

| Caustic potash KOH | 50% | 20° | 0 | 0 |

| Corrosive Agent | Concentration | Temp °C | Material | |

|---|---|---|---|---|

| A2 | A4 | |||

| Potassium permanganate K Mn O4 | all concentrations | 20° boiling | 0 0 | 0 0 |

| Calcium chloride L CaCL2, 6H2O | cold saturated | 20° | 0 | 0 |

| Calcium hydroxide Ca(OH)2 = milk of lime | – | 20° | 0 | 0 |

| Cheese | – | 20% | 0 | 0 |

| Carbon dioxide = carbonic acid CO2 | dry moist | hot hot | 0 0 | 0 0 |

| Carbon tetrachloride C CL4 | water free | 20° | 0 | 0 |

| Aqua regia L H CL + HNO3 | – | 20° | 3 | 3 |

| Cupric sulphate CuSO4, 5H20 = copper vitriol +3% H2SO4 | all concs. | 20° boiling 20° boiling | 0 0 0 0 | 0 0 0 0 |

| Glue (including acid) | – | boiling | 0 | 0 |

| Linseed oil +3% H2SO4 | – | 20° 200° | 0 0 | 0 0 |

| Magnesium sulphate MgSO4, 7H2O = Epsom salts | concentrated | 20° | 0 | 0 |

| Methyl alcohol CH3OH | all concentrations | 20° | 0 | 0 |

| Milk | fresh sour | up to 70° c up to 70° C | 0 0 | 0 0 |

| Lactic acid CH3 CHOH COOH | 1.5% 80% | 20° 20° | 0 0 | 0 0 |

| Mixed acids (nitrating acids) | 50% H2SO4 +50% HNO3 75% H2SO4 20% H2SO4 70% H2SO4 + 10% HNO3 30% H2SO4 | 50 ° 50 ° 50 ° 50° 50 ° | 0 1 0 0 0 | 0 0 0 0 0 |

| Monochloracetic acid L CH2 Cl COO H | 50% | 20° | 1 | 1 |

| Sodium chloride L NaCl = cooking salt | cold saturated hot saturated | 20° 100° | 0 1 | 0 0 |

| Sodium chloride L Na Cl O2 Sodium hydroxide =caustic soda solution =caustic soda NaOH | 5% 25% 50% | 20° boiling 20°boiling | 2 3 02 | 2 2 02 |

| Sodium hypochlorite L NaClO =bleaching solution | 5% | 20° boiling | 1 1 | 1 1 |

| Sodium carbonate Na2 CO3, 10 H2O | 10% cold saturated | boiling | 0 | 0 |

| Sodium sulphate Na2 SO4, 10 H2O | cold saturated | 20° | 0 | 0 |

| Novacaine | – | 20° | 0 | 0 |

| Fruit pulp containing SO2 | – | – | 0 | 0 |

| Oil (lubricating oil) | – | 20° | 0 | 0 |

| Oil (vegetable) | – | 20° | 0 | 0 |

| P3 washing agent | – | 95° | 0 | 0 |

| Persil | – | 20° and boiling | 0 | 0 |

| Petroleum | – | 20° | 0 | 0 |

| Phosphoric acid H3PO4 chemically pure | 1% 10% 45% 60% | 20 ° 20 ° 20 ° 20 ° | 0 0 0 0 | 0 0 0 0 |

| Photographic developer (Agfa-glyzin developer) | – | 20 ° | 0 | 0 |

| Photographic fixing bath L | – | 20 ° | 0 | 0 |

| Pickling brine L | – | 20 ° | 0 | 0 |

| Nitric acid HNO3 | 7% 10% 25% 37% 50% | 20 ° 20 ° 20 ° 20 ° 20 ° | 0 0 0 0 0 | 0 0 0 0 0 |

| Hydrochloric acid L HCl | 0.5% | 20 ° boiling | 1 3 | 1 3 |

| Sauerkraut brine L | – | – | 2 | 1 |

| Lard | – | 20 ° | 0 | 0 |

| Soft Soap | – | 20 ° | 0 | 0 |

| Sulphur, dry | fused | 130° | 0 | 0 |

| Carbon disulphide C S2 | – | 20° | 0 | 0 |

| Sulphuric acid H2SO4

fuming | 1% 2.5% 5% 7.5% 10% 98% – | 20° boiling 20° boiling 20° boiling 20 ° boiling 20 ° 20 ° 20 ° 70° 20° 70°20° 100° 20° 80° | 1 1 1 2 1 3 1 2 2 1 1 3 0 20 1 0 0 | 0 1 0 2 0 2 0 2 1 1 1 2 0 20 0 0 0 |

| Hydrogen sulphide dry H2S | <4 | 20° | 0 | 0 |

| Sulphurous acid H2 S O2 | saturated 4 bar 5-8 bar 10-20 bar | 20° 135° 160° 180-200° | 0 1 2 2 | 0 0 1 1 |

| Schweinfurt green 3 Cu (As O2)3, Cu (CH3 COO)2 | – | 20° | 0 | 0 |

| Sea Water L | – | 20° | 0 | 0 |

| Soap | – | 20° | 0 | 0 |

| Mustard L | – | 20° | 0 | 0 |

| Spinning bath | up to 10% H2SO4 | 70° | 2 | 1 |

| Tar (pure) | – | 20° and hot | 0 | 0 |

| Turpentine | – | 20° and hot | 0 | 0 |

| Vaseline | – | 20° and hot | 0 | 0 |

| Water Tap water Pit water = acidic water | – | 20° 20° | 0 0 | 0 0 |

| Water vapour Water vapour with SO2 Water vapour with CO2 | – – – | 400° – – | 0 1 0 | 0 0 0 |

| Wine (white and red) | – | 20° and hot | 0 0 | 0 0 |

| Tartaric acid COOH (CHOH)2 COOH | 10% 50% | 20° 20° | 0 0 | 0 0 |

| Lemon juice Citric acid HO C(CH2 COOH)2, COOH, H2) | – 1% 10% 25% 50% | 20° 20° 20° 20° 20° | 0 0 0 0 0 | 0 0 0 0 0 |

| Sugar solution | – | 20° boiling | 0 0 | 0 0 |

*All information is strictly informative

Fasteners Thread Identification Chart (British) Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Thread Identification Chart (British) / Fasteners Thread Identification Chart (British)

Thread Identification Chart (British)

| Basic Major Diameter | Nominal Diameter (mm) | Threads Per Inch | |||||

|---|---|---|---|---|---|---|---|

| Inch | mm | BA | BSW | BSF | BSP | BSPT | |

| .0118 | 0.30 | ||||||

| .0118 | 0.30 | ||||||

| .0138 | 0.35 | ||||||

| .0146 | 0.37 | 22 | 254 | ||||

| .0157 | 0.40 | ||||||

| .0165 | 0.42 | 21 | 231 | ||||

| .0177 | 0.45 | ||||||

| .0189 | 0.48 | 20 | 211 3/4 | ||||

| .0197 | 0.50 | ||||||

| .0209 | 0.53 | ||||||

| .0213 | 0.54 | 19 | 181 1/2 | ||||

| .0217 | 0.55 | ||||||

| .0236 | 0.60 | ||||||

| .0244 | 0.62 | 18 | 169 1/4 | ||||

| .0276 | 0.70 | 17 | 149 1/2 | ||||

| .0311 | 0.79 | 16 | 133 3/4 | ||||

| .0315 | 0.80 | ||||||

| .0340 | 0.86 | ||||||

| .0354 | 0.90 | 15 | 121 | ||||

| .0394 | 1.00 | 14 | 110 1/2 | ||||

| .0433 | 1.10 | ||||||

| .0470 | 1.19 | ||||||

| .0472 | 1.20 | 13 | 101 1/2 | ||||

| .0512 | 1.30 | 12 | 90 3/4 | ||||

| .0551 | 1.40 | ||||||

| .0591 | 1.50 | 11 | 82 | ||||

| .0600 | 1.52 | ||||||

| .0629 | 1.60 | ||||||

| .0669 | 1.70 | 10 | 72 1/2 | ||||

| .0709 | 1.80 | ||||||

| .0730 | 1.85 | ||||||

| .0748 | 1.90 | 9 | 65 | ||||

| .0787 | 2.00 | ||||||

| .0860 | 2.18 | ||||||

| .0866 | 2.20 | 8 | 59 | ||||

| .0906 | 2.30 | ||||||

| .0984 | 2.50 | 7 | 53 | ||||

| .0990 | 2.51 | ||||||

| .1024 | 2.60 | ||||||

| .1102 | 2.80 | 6 | 48 | ||||

| .1120 | 2.84 | ||||||

| .1181 | 3.00 | ||||||

| .1250 | 3.18 | 1/8 | 40 | ||||

| .1260 | 3.20 | 5 | 43 | ||||

| .1380 | 3.50 | ||||||

| .1417 | 3.60 | 4 | 38 1/2 | ||||

| .1575 | 4.00 | ||||||

| .1614 | 4.10 | 3 | 34 3/4 | ||||

| .1640 | 4.17 | ||||||

| .1772 | 4.50 | ||||||

| .1850 | 4.70 | 2 | 31 3/4 | ||||

| .1875 | 4.76 | 3/16 | 24 | 32 | |||

| .1900 | 4.83 | ||||||

| .1969 | 5.00 | ||||||

| .2087 | 5.30 | 1 | 28 1/4 | ||||

| .2160 | 5.49 | ||||||

| .2165 | 5.50 | ||||||

| .2188 | 5.56 | 7/32 | 28 | ||||

| .2362 | 6.00 | 0 | 25 1/2 | ||||

| .2500 | 6.35 | 1/4 | 20 | 26 | |||

| .2756 | 7.00 | ||||||

| .2812 | 7.14 | 9/32 | 26 | ||||

| .3125 | 7.94 | 5/16 | 18 | 22 | |||

| .3125 | 7.94 | ||||||

| .3150 | 8.00 | ||||||

| .3543 | 9.00 | ||||||

| .3750 | 9.53 | 3/8 | 16 | 20 | 28 | ||

| .3830 | 9.73 | 1/8 | 28 | ||||

| .3937 | 10.00 | ||||||

| .4050 | 10.29 | ||||||

| .4331 | 11.00 | ||||||

| .4375 | 11.11 | 7/16 | 14 | 18 | |||

| .4724 | 12.00 | ||||||

| .5000 | 12.70 | 1/2 | 12 | 16 | |||

| .5180 | 13.16 | ||||||

| .5400 | 13.72 | ||||||

| .5512 | 14.00 | ||||||

| .5625 | 14.29 | 9/16 | 12 | 16 | |||

| .6250 | 15.88 | 5/8 | 11 | 14 | |||

| .6299 | 16.00 | ||||||

| .6560 | 16.66 | 3/8 | 19 | 19 | |||

| .6750 | 17.15 | ||||||

| .6875 | 17.46 | 11/16 | 11 | 14 | |||

| .7087 | 18.00 | ||||||

| .7500 | 19.05 | 3/4 | 10 | 12 | |||

| .7874 | 20.00 | ||||||

| .8125 | 20.64 | 13/16 | 12 | ||||

| .8250 | 20.96 | 1/2 | 14 | ||||

| .8400 | 21.34 | 14 | |||||

| .8661 | 22.00 | ||||||

| .8750 | 22.23 | 7/8 | 9 | 11 | |||

| .9020 | 22.91 | 5/8 | 14 | 14 | |||

| .9375 | 23.81 | ||||||

| .9449 | 24.00 | ||||||

| 1.0000 | 25.40 | 1 | 8 | 10 | |||

| 1.0236 | 26.00 | ||||||

| 1.041011 | 26.44 | 3/4 | 14 | 14 | |||

| 1.0500 | 26.67 | ||||||

| 1.0625 | 26.99 | ||||||

| 1.0630 | 27.00 | ||||||

| 1.1250 | 28.58 | 1 1/8 | 7 | 9 | |||

| 1.1811 | 30.00 | ||||||

| 1.1875 | 30.16 | ||||||

| 1.1890 | 30.20 | 7/8 | 14 | 14 | |||

| 1.2500 | 31.75 | 1 1/4 | 7 | 9 | |||

| 1.2598 | 32.00 | ||||||

| 1.2992 | 33.00 | ||||||

| 1.3090 | 33.25 | 1 | 11 | 11 | |||

| 1.3125 | 33.34 | ||||||

| 1.3150 | 33.40 | ||||||

| 1.3750 | 34.93 | 1 3/8 | 8 | ||||

| 1.3780 | 35.00 | ||||||

| 1.4173 | 36.00 | ||||||

| 1.4375 | 36.51 | ||||||

| 1.4920 | 37.90 | 1 1/8 | 11 | ||||

| 1.4961 | 38.00 | ||||||

| 1.5000 | 38.10 | 1 1/2 | 6 | 8 | |||

| 1.5354 | 39.00 | ||||||

| 1.5625 | 39.69 | ||||||

| 1.5748 | 40.00 | ||||||

| 1.6250 | 41.28 | 1 5/8 | 8 | ||||

| 1.6500 | 41.91 | 1 1/4 | 11 | 11 | |||

| 1.6535 | 42.00 | ||||||

| 1.6600 | 42.16 | ||||||

| 1.6875 | 42.86 | ||||||

| 1.7450 | 44.32 | 1 3/8 | 11 | ||||

BSW-British Standard Whitworth

BSF-British Standard Fine

BSP-British Standard Pipe

BSPT-British

Standard Pipe Tapered

*All information is strictly informative

Fasteners Retaining Ring (Heavy Duty ) Series 2160-5160 Specifications Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners Retaining Ring (Heavy Duty ) Series 2160-5160 Specifications / Fasteners Retaining Ring (Heavy Duty ) Series 2160-5160 Specifications

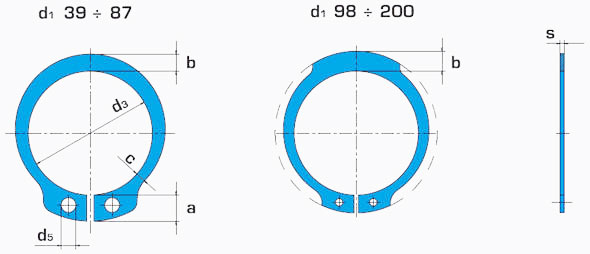

Retaining Ring (Heavy Duty ) Series 2160-5160 Specifications

Retaining Ring (Heavy Duty ) Series 2160-5160 Specifications

All measurements in millimeters (mm)

| Ring n° | d1 | s | d3 | a | b | c | d5 | d2 | m | n | FN | FR | g | FRg | nabl | lbs | Tool | Ring n° | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 0.500 | 0.047 | +0.002 | 0.460 | +0.005 | 0.120 | +0.004 | 0.090 | +0.005 | 0.050 | +0.005 | 0.050 | +0.010 | 0.468 | +0.001 | 0.056 | +0.004 | 0.048 | 1100 | 3959 | 0.058 | 650 | 65000 | 1.600 | A0 | A01 | 50 |

| -0.002 | -0.010 | -0.004 | -0.005 | -0.005 | -0.002 | -0.002 | -0.000 | ||||||||||||||||||||

| 62 | 0.625 | 0.049 | +0.002 | 0.575 | +0.005 | 0.130 | +0.004 | 0.106 | +0.005 | 0.059 | +0.005 | 0.050 | +0.010 | 0.588 | +0.001 | 0.056 | +0.004 | 0.057 | 1600 | 4872 | 0.062 | 750 | 49000 | 2.300 | A0 | A01 | 62 |

| -0.002 | -0.010 | -0.004 | -0.005 | -0.005 | -0.002 | -0.003 | -0.000 | ||||||||||||||||||||

| 75 | 0.750 | 0.078 | +0.003 | 0.689 | +0.005 | 0.180 | +0.005 | 0.127 | +0.006 | 0.077 | +0.006 | 0.078 | +0.015 | 0.704 | +0.001 | 0.086 | +0.005 | 0.069 | 2400 | 9135 | 0.074 | 2500 | 40500 | 5.600 | A1 | A11 | 75 |

| -0.003 | -0.010 | -0.005 | -0.006 | -0.006 | -0.002 | -0.003 | -0.000 | ||||||||||||||||||||

| 98 | 1.000 | 0.078 | +0.003 | 0.906 | +0.005 | 0.181 | +0.006 | 0.181 | +0.006 | 0.084 | +0.006 | 0.098 | +0.000 | 0.938 | +0.001 | 0.086 | +0.005 | 0.093 | 4000 | 11673 | 0.083 | 2500 | 30000 | 7.800 | A1 | A11 | 98 |

| -0.003 | -0.010 | -0.006 | -0.006 | -0.006 | -0.008 | -0.003 | -0.000 | ||||||||||||||||||||

| 106 | 1.062 | 0.093 | +0.003 | 0.978 | +0.010 | 0.181 | +0.006 | 0.181 | +0.006 | 0.090 | +0.007 | 0.093 | +0.015 | 0.998 | +0.002 | 0.103 | +0.005 | 0.096 | 4800 | 15225 | 0.088 | 4000 | 27000 | 11.500 | A1 | A11 | 106 |

| -0.003 | -0.015 | -0.006 | -0.006 | -0.007 | -0.002 | -0.004 | -0.000 | ||||||||||||||||||||

| 112 | 1.125 | 0.093 | +0.003 | 1.036 | +0.010 | 0.181 | +0.006 | 0.181 | +0.006 | 0.095 | +0.007 | 0.093 | +0.015 | 1.059 | +0.002 | 0.103 | +0.005 | 0.099 | 5200 | 16240 | 0.093 | 4000 | 26000 | 12.500 | A1 | A11 | 112 |

| -0.003 | -0.015 | -0.006 | -0.006 | -0.007 | -0.002 | -0.004 | -0.000 | ||||||||||||||||||||

| 118 | 1.181 | 0.093 | +0.003 | 1.087 | +0.010 | 0.213 | +0.006 | 0.213 | +0.006 | 0.098 | +0.007 | 0.108 | +0.000 | 1.111 | +0.002 | 0.103 | +0.005 | 0.105 | 5600 | 16748 | 0.093 | 4000 | 24000 | 13.500 | A2 | A21 | 118 |

| -0.003 | -0.015 | -0.006 | -0.006 | -0.007 | -0.010 | -0.004 | -0.000 | ||||||||||||||||||||

| 125 | 1.250 | 0.093 | +0.003 | 1.150 | +0.010 | 0.213 | +0.006 | 0.213 | +0.006 | 0.103 | +0.007 | 0.108 | +0.000 | 1.174 | +0.002 | 0.103 | +0.005 | 0.114 | 6500 | 17763 | 0.093 | 4000 | 23000 | 14.900 | A2 | A21 | 125 |

| -0.003 | -0.015 | -0.006 | -0.006 | -0.007 | -0.010 | -0.004 | -0.000 | ||||||||||||||||||||

| 131 | 1.312 | 0.093 | +0.003 | 1.208 | +0.010 | 0.213 | +0.006 | 0.213 | +0.006 | 0.106 | +0.007 | 0.108 | +0.000 | 1.234 | +0.002 | 0.103 | +0.005 | 0.117 | 7400 | 18270 | 0.107 | 4000 | 21500 | 1.600 | A2 | A21 | 131 |

| -0.003 | -0.015 | -0.006 | -0.006 | -0.007 | -0.010 | -0.004 | -0.000 | ||||||||||||||||||||

| 137 | 1.375 | 0.093 | +0.003 | 1.268 | +0.010 | 0.213 | +0.006 | 0.213 | +0.006 | 0.110 | +0.007 | 0.108 | +0.000 | 1.291 | +0.002 | 0.103 | +0.005 | 0.126 | 8200 | 19793 | 0.107 | 4000 | 20500 | 17.800 | A2 | A21 | 137 |

| -0.003 | -0.015 | -0.006 | -0.006 | -0.007 | -0.010 | -0.004 | -0.000 | ||||||||||||||||||||

| 150 | 1.500 | 0.109 | +0.003 | 1.380 | +0.010 | 0.213 | +0.006 | 0.213 | +0.006 | 0.096 | +0.008 | 0.108 | +0.000 | 1.406 | +0.002 | 0.120 | +0.005 | 0.141 | 10000 | 24868 | 0.107 | 5000 | 18500 | 17.000 | A2 | A21 | 150 |

| -0.003 | -0.015 | -0.006 | -0.006 | -0.008 | -0.010 | -0.004 | -0.000 | ||||||||||||||||||||

| 156 | 1.562 | 0.109 | +0.003 | 1.437 | +0.013 | 0.213 | +0.006 | 0.213 | +0.006 | 0.098 | +0.008 | 0.108 | +0.000 | 1.468 | +0.003 | 0.120 | +0.005 | 0.141 | 10400 | 26390 | 0.107 | 5000 | 17000 | 31.000 | A2 | A21 | 156 |

| -0.003 | -0.020 | -0.006 | -0.006 | -0.008 | -0.010 | -0.004 | -0.000 | ||||||||||||||||||||

| 175 | 1.750 | 0.109 | +0.003 | 1.608 | +0.013 | 0.213 | +0.006 | 0.213 | +0.006 | 0.106 | +0.008 | 0.108 | +0.000 | 1.650 | +0.003 | 0.120 | +0.005 | 0.150 | 12400 | 29435 | 0.107 | 5000 | 15500 | 33.400 | A2 | A21 | 175 |

| -0.003 | -0.020 | -0.006 | -0.006 | -0.008 | -0.010 | -0.004 | -0.000 | ||||||||||||||||||||

| 193 | 1.938 | 0.125 | +0.004 | 1.782 | +0.013 | 0.295 | +0.008 | 0.295 | +0.008 | 0.154 | +0.008 | 0.125 | +0.015 | 1.826 | +0.003 | 0.139 | +0.006 | 0.168 | 15300 | 37555 | 0.128 | 6000 | 14300 | 48.000 | A3 | A31 | 193 |

| -0.004 | -0.020 | -0.008 | -0.008 | -0.008 | -0.002 | -0.004 | -0.000 | ||||||||||||||||||||

| 193 | 1.969 | 0.125 | +0.004 | 1.782 | +0.013 | 0.295 | +0.008 | 0.295 | +0.008 | 0.154 | +0.008 | 0.125 | +0.015 | 1.850 | +0.003 | 0.139 | +0.006 | 0.180 | 15300 | 37555 | 0.128 | 6000 | 14100 | 48.000 | A3 | A31 | 193 |

| -0.004 | -0.020 | -0.008 | -0.008 | -0.008 | -0.002 | -0.004 | -0.000 | ||||||||||||||||||||

| 200 | 2.000 | 0.125 | +0.004 | 1.840 | +0.013 | 0.295 | +0.008 | 0.295 | +0.008 | 0.160 | +0.008 | 0.125 | +0.015 | 1.880 | +0.003 | 0.139 | +0.006 | 0.180 | 17000 | 38570 | 0.128 | 6000 | 14000 | 50.600 | A3 | A31 | 200 |

| -0.004 | -0.020 | -0.008 | -0.008 | -0.008 | -0.002 | -0.004 | -0.000 | ||||||||||||||||||||

*All information is strictly informative

Fasteners DIN / ISO / EN Crossover Chart Dimensions, Weight Chart & Material Specification & Tolerances / Fasteners DIN / ISO / EN Crossover Chart / Fasteners DIN / ISO / EN Crossover Chart

DIN / ISO / EN Crossover Chart

| Title DIN Standard | DIN | DIN EN ISO | DIN EN | DIN ISO | Comparable ISO Standard | Date of current standard/modified | Title of replacement standard | Comment |

|---|---|---|---|---|---|---|---|---|

| All-metal prevailing torque type hexagon nuts | 980 | 7042 | 27042 | 7042 | 1998-02 | Prevailing torque type (all-metal hexagon nuts), style 2 – Property classes 5, 8, 10 and 12 | Height of nut changed; width across flat according to ISO 272 included | |

| All-metal prevailing torque type hexagon nuts | 980 | 10513 | 30513 | 10513 | 1998-02 | Prevailing torque type all-metal hexagon nuts, style 2, with metric fine pitch thread – Property classes 8, 10 and 12 | Height of nut changed; width across flat according to ISO 272 included | |

| Clevis pins with head | 1434 | 22341 | 2341 | 1992-10 | Clevis pins with head | Only one head dimension. Some other nominal lengths defined | ||

| Clevis pins with head | 1435 | 22341 | 2341 | 1992-10 | Clevis pins with head | Only one head dimension. Some other nominal lengths defined | ||

| Clevis pins with head | 1436 | 22341 | 2341 | 1992-10 | Clevis pins with head | Only one head dimension. Some other nominal lengths defined | ||

| Clevis pins with head | 1444 | 22341 | 2341 | 1992-10 | Clevis pins with head | Some other nominal lengths defined | ||

| Clevis pins without head | 1433 | 22340 | 2340 | 1992-10 | Clevis pins without head | Some other nominal lengths defined | ||

| Clevis pins without head | 1443 | 22340 | 2340 | 1992-10 | Clevis pins without head | |||

| Countersunk (flat) head tapping screws with cross recess | 7982 | 7050 | 7050 | 1990-08 | Cross recessed countersunk (flat) head tapping screws (common head style) | Head dimensions and countersunk angles changed | ||

| Cross recessed countersunk (flat) head screws (Countersunk heads according to ISO) | 965 | 7046-1 | 7046 | 7046-1 | 1994-10 | Countersunk flat head screws (common head style) with type H or type Z cross recess – Property class 4.8 | Nominal size changed; head dimension changed; thread length changed; strength 8.8 included (see Part 2); penetration depth of cross slots changed | |

| Cross recessed countersunk (oval) head screws (Countersunk heads according to ISO) | 966 | 7047 | 7047 | 7047 | 1994-10 | Countersunk raised head screws (common head style) with type H or type Z cross recess – Product grade A | Nominal size changed; head dimension changed; thread length changed; strength 8.8 omitted; penetration depth of cross slots changed | |

| Cross recessed countersunk head drilling screws with tapping screw thread | 7504 | 15482 | 15482 | 2000-02 | Cross recessed countersunk head drilling screws with tapping screw thread | Standard divided into five single standards (EN ISO 10666, 15480, 15481, 15482, 15483); thread ST 3.9 omitted; hexagon head with collar and slot (Form L) omitted | ||

| Cross recessed pan head drilling screws with tapping screw thread | 7504 | 15481 | 15481 | 2000-02 | Cross recessed pan head drilling screws with tapping screw thread | Standard divided into five single standards (EN ISO 10666, 15480, 15481, 15482, 15483); thread ST 3.9 omitted; hexagon head with collar and slot (Form L) omitted | ||

| Cross recessed pan head tapping screws | 7981 | 7049 | 7049 | 1990-08 | Cross recessed pan head tapping screws | Marginal change of head dimensions. Caution with automatic feed and connection systems | ||

| Cross recessed raised countersunk head drilling screws with tapping screw thread | 7504 | 15483 | 15483 | 2000-02 | Cross recessed raised countersunk head drilling screws with tapping screw thread | Standard divided into five single standards (EN ISO 10666, 15480, 15481, 15482, 15483); thread ST 3.9 omitted; hexagon head with collar and slot (Form L) omitted | ||

| Drilling screws with tapping screw thread – Mechanical and functional properties | 7504 | 10666 | 10666 | 2000-02 | Drilling screws with tapping screw thread – Mechanical and functional properties | Standard divided into five single standards (EN ISO 10666, 15480, 15481, 15482, 15483); thread ST 3.9 omitted; hexagon head with collar and slot (Form L) omitted | ||

| Grooved pins – Full-length parallel grooved, with chamfer | 1473 | 8740 | 28740 | 8740 | 1998-03 | Grooved pins – Full-length parallel grooved, with chamfer | Nominal lengths redefined. Shear rate increased. | |

| Grooved pins – Fulllength parallel grooved, with pilot | 1470 | 8739 | 28739 | 8739 | 1998-03 | Grooved pins – Full-length parallel grooved, with pilot | Nominal lengths redefined. Shear rate increased. | |

| Grooved pins – Fulllength taper grooved | 1471 | 8744 | 28744 | 8744 | 1998-03 | Grooved pins – Full-length taper grooved | Nominal lengths redefined. Shear rate increased. | |

| Grooved pins – Half-length reverse-taper grooved | 1474 | 8741 | 28741 | 8741 | 1998-03 | Grooved pins – Half-length reverse-taper grooved | Nominal lengths redefined. Shear rate increased. | |

| Grooved pins – Half-length taper grooved | 1472 | 8745 | 28745 | 8745 | 1998-03 | Grooved pins – Half-length taper grooved | Nominal lengths redefined. Shear rate increased. | |

| Grooved pins – One-third-length centre grooved | 1475 | 8742 | 28742 | 8742 | 1998-03 | Grooved pins – One-third-length centre grooved | Nominal lengths redefined. Shear rate increased. | |

| Grooved pins with countersunk head | 1477 | 8747 | 28747 | 8747 | 1998-03 | Grooved pins with countersunk head | Chamfer redefined | |

| Grooved pins with round head | 1476 | 8746 | 28746 | 8746 | 1998-03 | Grooved pins with round head | Chamfer redefined | |

| Hexagon Bolts without Hexagon Nut – with Hexagon Nut, Type g | 601 | 4016 | 24016 | 4016 | 4016 | 2001-03 | Hexagon head bolts – Product grade C | Nominal size extended; width across flats according to DIN ISO 272 included |

| Hexagon bolts, Metric fine thread, Types m and mg | 960 | 8765 | 28765 | 8765 | 8765 | 2001-03 | Hexagon thin nuts (chamfered) with metric fine pitch thread – Product grades A and B | Nominal size extended; width across flats according to DIN ISO 272 included |

| Hexagon flange bolts | 6921 | 1665 | 8102 | 1998-11 | Hexagon bolts with flange, heavy series | Dimensions partially changed; width across flats according to ISO 272; strength 12.9 omitted | ||

| Hexagon head bolts with shank; M 1,6 to M 39 screw threads, Product grades A and B | 931-1 | 4014 | 24014 | 4014 | 4014 | 2001-03 | Hexagon head bolts – Product grades A and B | Nominal size extended; width across flats according to DIN ISO 272 included |

| Hexagon head screws – Product grades A and B | 933 | 4017 | 24017 | 4017 | 4017 | 2001-03 | Hexagon head screws – Product grades A and B | Nominal size extended; width across flats according to DIN ISO 272 included |

| Hexagon nuts with flange | 6923 | 1661 | 4161 | 1998-02 | Hexagon nuts with flange | Fine thread omitted to be included in a separate standard later); width across flat M10 changed | ||

| Hexagon nuts; Metric Thread, Type g | 555 | 4034 | 24034 | 4034 | 4034 | 2001-03 | Hexagon nuts – Product grade C | Width across flats according to DIN ISO 272 included; nominal diameter reduced |

| Hexagon nuts; Metric screw threads; Product grades A and B | 934 | 4032 | 24032 | 4032 | 4032 | 2001-03 | Hexagon nuts, style 1 – Product grades A and B | Nominal diameter changed, height of the nut changed partially; nuts with fine thread specified in DIN EN ISO 8673; width across flats according to DIN ISO 272 included |

| Hexagon nuts; Metric screw threads; Product grades A and B | 934 | 8673 | 28673 | 8673 | 2001-03 | Hexagon nuts, style 1, with metric fine pitch thread – Product grades A and B | Nominal diameter changed, height of the nut changed partially; nuts with regular type screw thread specified in DIN EN ISO 4032; width across flats according to DIN ISO 272 included | |

| Hexagon screws, Thread Approximately to Head, Metric Thread, Type g | 558 | 4018 | 24018 | 4018 | 4018 | 2001-03 | Hexagon head screws – Product grade C | Nominal size extended; width across flats according to DIN ISO 272 included |

| Hexagon socket countersunk head screws | 7991 | 10642 | 10462 | 2004-06 | Hexagon socket countersunk head screws | |||

| Hexagon socket head cap screws | 912 | 4762 | 4762 | 2004-06 | Hexagon socket head cap screws | Nominal size range changed; fine thread deleted (ISO 21269) | ||

| Hexagon socket set screws with cone point | 914 | 4027 | 4027 | 2004-05 | Hexagon socket set screws with cone point | Nominal sizes M1.4, M1.8, M14, M18 and M22 omitted | ||

| Hexagon socket set screws with cup point | 916 | 4029 | 4029 | 2004-05 | Hexagon socket set screws with cup point | |||

| Hexagon socket set screws with dog point | 915 | 4028 | 4028 | 2004-05 | Hexagon socket set screws with dog point | Nominal sizes M1.4, M1.8, M14, M18 and M22 omitted | ||

| Hexagon socket set screws with flat point | 913 | 4026 | 4026 | 2004-05 | Hexagon socket set screws with flat point | Nominal sizes M1.4, M1.8, M14, M18 and M22 omitted | ||

| Hexagon thin nuts with M 1,6 to M 10 threads | 439-1 | 4036 | 24036 | 4036 | 4036 | 2001-02 | Hexagon thin nuts (unchamfered) – Product grade B | Correlation of dimensions with DIN 439-1, except for the width across flat of the nut M10 |

| Hexagon thin nuts with M 1,6 to M 52 and M 8×1 to M 52×3 threads | 439-2 | 4035 | 24035 | 4035 | 2001-03 | Hexagon thin nuts (unchamfered) – Product grades A and B | In tables 1 and 2 abbreviations changed and some specifications (thread dimensions) changed | |

| Hexagon thin nuts with M 1,6 to M 52 and M 8×1 to M 52×3 threads | 439-2 | 4035 | 24035 | 4035 | 4035 | 2001-03 | Hexagon thin nuts (unchamfered) – Product grades A and B | Standard divided by regular type screw threads and fine threads; width across flats according to ISO 272 changed; nominal size range changed; fine thread see ISO 8675 |

| Hexagon thin nuts with M 1,6 to M 52 and M 8×1 to M 52×3 threads | 439-2 | 8675 | 28675 | 8675 | 2001-03 | Hexagon thin nuts (unchamfered) with metric fine pitch thread – Product grades A and B | Standard divided by regular type screw threads and fine threads; width across flats according to ISO 272 changed; nominal size range changed; regular type screw thread see ISO 4035 | |

| Hexagon washers head drilling screws with tapping screw thread | 7504 | 15480 | 15480 | 2000-02 | Hexagon washers head drilling screws with tapping screw thread | Standard divided into five single standards (EN ISO 10666, 15480, 15481, 15482, 15483); thread ST 3,9 omitted; hexagon head with collar and slot (Form L) omitted | ||

| High-strength hexagon head bolts with large widths across flats for structural steel bolting | 6914 | 14399-4 | 7412 | 2006-06 | High-strength structural bolting assemblies for preloading – Part 4: System HV – Hexagon bolt and nut assemblies | |||

| High-strength hexagon nuts with large widths across flats for structural steel bolting | 6915 | 14399-4 | 2006-06 | High-strength structural bolting assemblies for preloading – Part 4: System HV – Hexagon bolt and nut assemblies | ||||

| M 8×1 to M 100×4 hexagon head bolts with fine pitch thread | 961 | 8676 | 28676 | 8676 | 8676 | 2001-03 | Hexagon head screws with metric fine pitch thread – Product grades A and B | Nominal size extended; width across flats according to DIN ISO 272 included |

| Mushroom head square neck bolts | 603 | 8677 | 1981-10 | |||||

| Parallel pins of unhardened steel and austenitic stainless steel | 7 | 2338 | 22338 | 2338 | 1998-02 | Parallel pins of unhardened steel and austenitic stainless steel | Nominal length redefined (with round end) form A+C deleted | |

| Parallel pins with internal thread | 7979 | 8735 | 28735 | 8735 | 1998-03 | Parallel pins with internal thread, of hardened and martensitic stainless steel | Dimensions partially changed | |

| Parallel pins with internal thread, of unhardened and austenitic stainless steel | 7979 | 8733 | 28733 | 8733 | 1998-03 | Parallel pins with internal thread, of unhardened and austenitic stainless steel | Dimensions partially changed | |

| Parallel pins, Hardened; Tolerance Zone m6 | 6325 | 8734 | 28734 | 8734 | 1998-03 | Parallel pins of hardened and martensitic stainless steel (Dowel pins) | Some other nominal lengths defined | |

| Plain washers – Extra large series, product grade C | 440 | 7094 | 7094 | 2000-12 | Plain washers – Extra large series, product grade C | Nominal sizes changed, nominal size 24 size “a” redefined to the maximum, square-end hole Form R omitted; (standard DIN 440 still valid) | ||

| Plain washers for clevis pins; product grade A | 1440 | 28738 | 8738 | 1992-10 | Plain washers for clevis pins; product grade A | Nominal sizes changed | ||

| Prevailing torque type – All-metal hexagon nuts with flange | 6927 | 1664 | 7044 | 1998-02 | Prevailing torque type – All-metal hexagon nuts with flange | Width across flat M10 changed | ||

| Prevailing torque type all-metal hexagon nuts | 6925 | 7042 | 27042 | 7042 | 1998-02 | Prevailing torque type (all-metal hexagon nuts), style 2 – Property classes 5, 8, 10 and 12 | Height of nut changed; width across flat according to ISO 272 included | |

| Prevailing torque type all-metal hexagon nuts | 6925 | 10513 | 30513 | 10513 | 1998-02 | Prevailing torque type all-metal hexagon nuts, style 2, with metric fine pitch thread – Property classes 8, 10 and 12 | Height of nut changed; width across flat according to ISO 272 included | |

| Prevailing torque type hexagon nuts with flange (with non-metallic insert), with metric fine pitch thread | 6926 | 1666 | 12125 | 1998-02 | Prevailing torque type hexagon nuts with flange (with non-metallic insert), with metric fine pitch thread | Width across flat M10 changed | ||

| Prevailing torque type hexagon nuts with non-metallic insert | 982 | 7040 | 27040 | 7040 | 1998-02 | Prevailing torque type hexagon nuts (with non-metallic insert), style 1 – Property classes 5, 8 and 10 | Height of nut changed; width across flat according to ISO 272 included | |

| Prevailing torque type hexagon nuts with non-metallic insert | 982 | 10512 | 30512 | 10512 | 1998-02 | Prevailing torque type hexagon nuts (with non-metallic insert), style 1, with metric fine pitch thread – Property classes 6, 8 and 10 | Height of nut changed; width across flat according to ISO 272 included | |

| Prevailing torque type hexagon nuts with non-metallic insert | 6924 | 7040 | 27040 | 7040 | 1998-02 | Prevailing torque type hexagon nuts (with non-metallic insert), style 1 – Property classes 5, 8 and 10 | Height of nut changed; width across flat according to ISO 272 included | |

| Prevailing torque type hexagon nuts with non-metallic insert | 6924 | 10512 | 30512 | 10512 | 1998-02 | Prevailing torque type hexagon nuts (with non-metallic insert), style 1, with metric fine pitch thread – Property classes 6, 8 and 10 | Height of nut changed; width across flat according to ISO 272 included | |

| Prevailing torque type hexagon thin nuts with non-metallic insert | 985 | 10511 | 10511 | 1998-02 | Prevailing torque type hexagon, thin nuts (with non-metallic insert) | Height of nut changed; width across flat according to ISO 272 included | ||

| Product grade A washers with a hardness from 300 HV, designed for use with hexagon head bolts and nuts | 125-2 | 7089 | 7089 | 2000-11 | Plain washers – Normal series, Product grade A | Without chamfer, up to nominal diameter 64 | ||

| Product grade A washers with a hardness from 300 HV, designed for use with hexagon head bolts and nuts | 125-2 | 7090 | 7090 | 1990-03 | Plain washers, chamfered – Normal series, Product grade A | Without chamfer, up to nominal diameter 64 | ||

| Product grade A washers with a hardness up to 250 HV, designed for use with cheese head screws | 433-1 | 7092 | 7092 | 2000-11 | Plain washers – Small series, Product grade A | Pyramid diamond hardness 140 HV cancelled; rating changed | ||

| Product grade A washers with a hardness up to 250 HV, designed for use with hexagon head bolts and nuts | 125-1 | 7089 | 7089 | 2000-11 | Plain washers – Normal series, Product grade A | Without chamfer, up to nominal diameter 64 | ||